Looking for ways to improve the look and functionality of your home? Consider investing in awnings for doors and windows. Awnings offer effective protection from the sun’s harsh rays, helping to keep your home cool and comfortable no matter how hot it gets outside.

Looking for ways to improve the look and functionality of your home? Consider investing in awnings for doors and windows. Awnings offer effective protection from the sun’s harsh rays, helping to keep your home cool and comfortable no matter how hot it gets outside.

Additionally, they can add style and curb appeal to your property, making them a great way to improve your home’s overall appearance. If you’re looking for ways to improve your home, awnings are a great option to consider.

What Is an Awning?

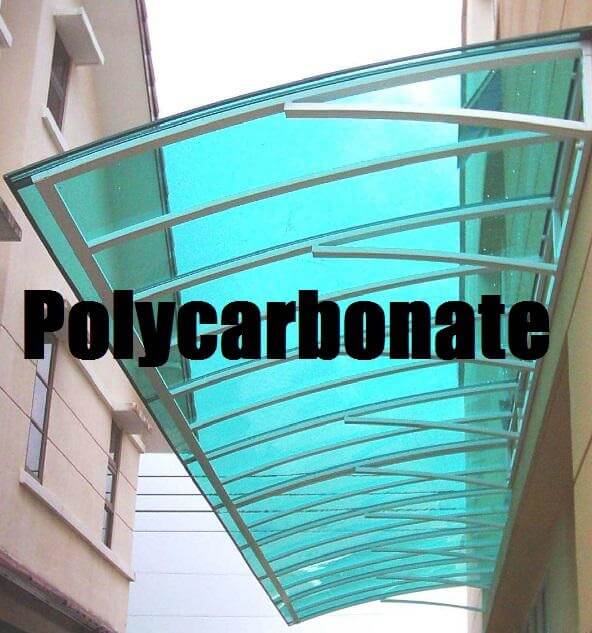

An awning is a type of exterior covering that is typically used to provide shade and protection from the sun’s harsh rays. It is typically made of lightweight material, such as fabric or polycarbonate, and is attached to the outside of doors or windows to provide sun protection.

There are different types of awnings available on the market, each with its own unique set of benefits. The type of awning you choose will depend on your specific needs and preferences.

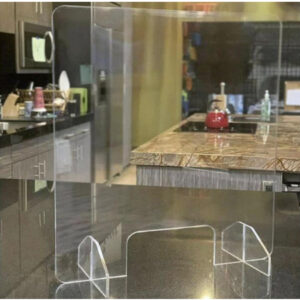

Some popular choices include fixed awnings, retractable awnings, motorized awnings, and canvas awnings. The latest trend in awnings is to opt for ones made of polycarbonate that are fixed on a frame made of a powder-coated aluminum frame.

Benefits of Investing in Awnings for Your Doors & Windows

Awnings are a popular choice for homeowners looking to improve the appearance and functionality of their homes. Below we list some of the main reasons why you should invest in awnings for your doors and windows.

- Awnings Provide Protection from the Sun’s Harsh Rays: Awnings are an excellent way to reduce heat gain in your home, helping to keep you cool and comfortable no matter how hot it gets outside.

- Awnings Can Help Prevent Fading of Fabrics and Furniture: The sun’s ultraviolet rays can cause fabrics and furniture to fade over time. Awnings can help prevent this by blocking the sun’s harmful rays, thus protecting your belongings from fading.

- Awnings Offer Privacy in Your Home: Awnings can be used to create a more private setting in your home, blocking the view of nosy neighbors or passersby.

- Awnings Can Add Style and Curb Appeal to Your Home: Awnings come in a variety of colors, styles, and materials, so you’re sure to find an option that complements the look of your home.

- Awnings Can Help Increase Energy Efficiency in Your Home: Awnings can block the sun’s heat from entering your home, helping to keep your home cool and reducing the need for air conditioning.

- Awnings Can Be Used to Create Outdoor Living Spaces: Awnings can be used to create a comfortable outdoor living space where you can sit and relax or entertain guests.

- Awnings Are Highly Durable and Long-Lasting: Awnings are built to withstand the elements and last for many years with proper care and maintenance.

- Awnings Are Easy to Care For: Awnings are typically made of materials that are easy to clean and require little maintenance.

- Awnings Are Affordable: Awnings are a more affordable option than other home improvement projects, such as window replacement or additions.

- Awnings Increase the Value of Your Home: Awnings are a great way to improve the appearance and functionality of your home, making them an excellent investment that can help increase the value of your property.

- Awning Protects Your Home From Water Damage: Awnings direct rainfall away from your home, helping to protect your property from water damage and leaks.

Choose the Best Awnings for Your Needs

When considering awnings for your home, don’t forget to take a closer look at aluminum door awnings. These types of awnings are a great option for adding protection to your home’s entryway while also providing a sleek and modern look.

Aluminum door awnings are typically lightweight and durable, making them an ideal choice for those looking for a long-lasting solution. They come in a variety of styles and colors, allowing you to choose the perfect match for your home’s exterior.

Additionally, aluminum door awnings can help to reduce energy costs by providing shade and keeping your home cooler in the summer months. They also offer protection from the elements, such as rain and snow, helping to keep your entryway dry and safe.

When shopping for aluminum door awnings, be sure to consider the size of your doorway and choose an option that fits comfortably. You’ll also want to factor in your budget, as well as any additional features you may want, such as retractable options or custom graphics.

Contact Canada Plastics & Belting for Awnings for Doors & Windows

Canada Plastics & Belting Inc. is one of the leading polycarbonate sheet suppliers in North America. Our company is based in Canada, and we offer a wide range of high-quality polycarbonate sheets that are perfect for awnings, doors, windows, and other home improvement projects. Contact us today to learn more about our products and to see how we can help you achieve your home improvement goals!

Despite boasting a durable and scratch-resistant surface,

Despite boasting a durable and scratch-resistant surface,

Considering it’s one of the most versatile and durable materials in the world, there are countless uses of acrylic sheets. Acrylic sheet suppliers and distributors provide their materials to various industrial and commercial businesses that manufacture many different types of structures and products.

Considering it’s one of the most versatile and durable materials in the world, there are countless uses of acrylic sheets. Acrylic sheet suppliers and distributors provide their materials to various industrial and commercial businesses that manufacture many different types of structures and products.

Conveyor belts are made of a variety of materials including metal, rubber, fabric, thermoplastics, and leather.

Conveyor belts are made of a variety of materials including metal, rubber, fabric, thermoplastics, and leather.

Over the past few years, polycarbonate twin wall sheet suppliers in Canada have been very busy fulfilling large orders for their signature products. These thermoplastic building materials are the perfect replacement for glass. They’re made to mimic the appearance and certain characteristics of glass, but they have a lot more advantages. They can be used for a number of different construction projects. In fact,

Over the past few years, polycarbonate twin wall sheet suppliers in Canada have been very busy fulfilling large orders for their signature products. These thermoplastic building materials are the perfect replacement for glass. They’re made to mimic the appearance and certain characteristics of glass, but they have a lot more advantages. They can be used for a number of different construction projects. In fact,