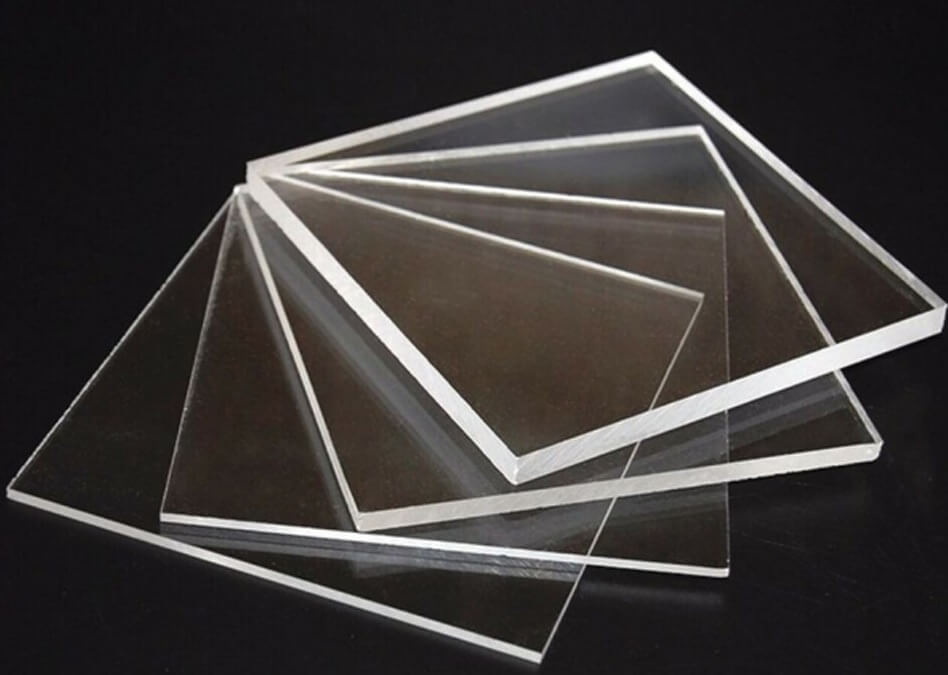

Plexiglass is a plastic material made from polymers of methyl methacrylate (PMMA). It is one of the most sought-after plastic materials, and the reason is simple: it is a better alternative to glass because of its flexibility, UV resistance, lightweight, transparency, high impact, and chemical resistance.

Plexiglass is a plastic material made from polymers of methyl methacrylate (PMMA). It is one of the most sought-after plastic materials, and the reason is simple: it is a better alternative to glass because of its flexibility, UV resistance, lightweight, transparency, high impact, and chemical resistance.

Glass is an amorphous solid made from raw materials such as sand, silica, soda, and lime that are melted at very high temperatures to form a new material.

Plexiglass and glass are popular materials used for different applications. But when you look at both materials, you may wonder: What are the similarities and differences? Comparing plexiglass and glass is crucial because both materials have distinct advantages and disadvantages that make them suitable for specific applications. Knowing this will help in selecting the most suitable material for diverse applications.

Strength and Durability

Glass is inherently prone to scratches. Glass is also brittle, so when it is subjected to stress, it breaks easily into sharp shards. On the other hand, it is very unlikely for plexiglass to break, and when it does, it will fracture into pieces with rounded edges. Plexiglass is 10 times more impact and shatter-resistant than glass.

Cost and Affordability

Plexiglass is cheaper than glass due to the raw materials needed for forming and production. You need silica sand, soda ash, and limestone to make glass, and a rise in the cost of any of these materials will influence the cost of production. Plexiglass is made from polymers of methyl methacrylate.

Plexiglass can be manufactured using methods like extrusion and injection molding, which can streamline production and reduce associated costs. Plexiglass melts at a much lower temperature, while glass melts between 1,400 °C to 1,600 °C, meaning plexiglass requires significantly less energy to shape and manufacture.

Another factor that contributes to the high cost of glass is its heavy weight. Plexiglass weighs 50% less than glass of equal thickness. Hence, transporting plexiglass is easier and cheaper than glass.

Applications in Construction and Architecture

Plexiglass is highly impact-resistant, making it a safer option for windows and facades, especially for areas prone to extreme weather conditions or potential impacts, because it can withstand harsh or unfavourable conditions and still allows light to penetrate through it.

Plexiglass is also three to eight times more thermally insulating than regular glass windows. However, prolonged exposure to sunlight can cause plexiglass to turn yellow and lose its optical clarity due to UV degradation. When it comes to safety, plexiglass is a better option. Glass can shatter upon intense impact, creating potential safety hazards.

Design and Aesthetics

One thing about plexiglass that cannot go unnoticed is its aesthetic appeal. Plexiglass comes in different colours and can easily blend with the interior design of your building. When plexiglass is used as tabletops, shower enclosures, coffee tables, bed frames, etc., it gives the house a sophisticated feel. Glass furniture adds charm to the home and it can maintain its sleek and beautiful look for a long time. Plexiglass is more flexible than glass; it can be made into any desired shape.

Optical Clarity and Light Transmission

Both glass and plexiglass sheets are transparent; however, plexiglass has better optical clarity. Plexiglass has a light transmittance of 0.93, meaning plexiglass transmits more than 90% of light. Glass, on the other hand, ranges between 0.80 and 0.90. It transmits more light, but the thicker the glass is, the more it discoulors. Plexiglass maintains its clarity consistently regardless of its thickness.

Environmental Impact and Sustainability

Glass is produced at extremely high temperatures, releasing more CO2 into the ecosystem. Plexiglass, on the other hand, is produced with less energy. Both Plexiglass and glass can be fully recycled but recycling plexiglass is a bit harder than glass.

Safety Considerations and Regulations

Plexiglass is a flammable material and, therefore, not recommended for places prone to high temperatures or open flames. One advantage, however, is that plexiglass forms no embers, which makes it easy to extinguish with little water in the event of a fire, unlike glass, which is a brittle material and is more likely to shatter and fuel the fire.

Sharp glass pieces can cut deeply. Finely crushed glass can irritate the eyes and inhaling it can hurt the lungs. Plexiglass, on the other hand, doesn’t let toxic or harmful substances. Both glass and plexiglass comply with several industry safety standards such as automotive, food, healthcare, construction, etc.

Choose Canada Plastics and Belting Inc. for Plexiglass Sheets

Both glass and plexiglass have their unique properties and, as such, are suited for different applications. It is your responsibility to know when and where to use plexiglass sheets. If you want a more scratch-resistant material, that is durable, lighter, versatile, and shatter-resistant, then plexiglass is the right material. Contact Canada Plastic and Belting Inc. for plexiglass sheets for your next project.

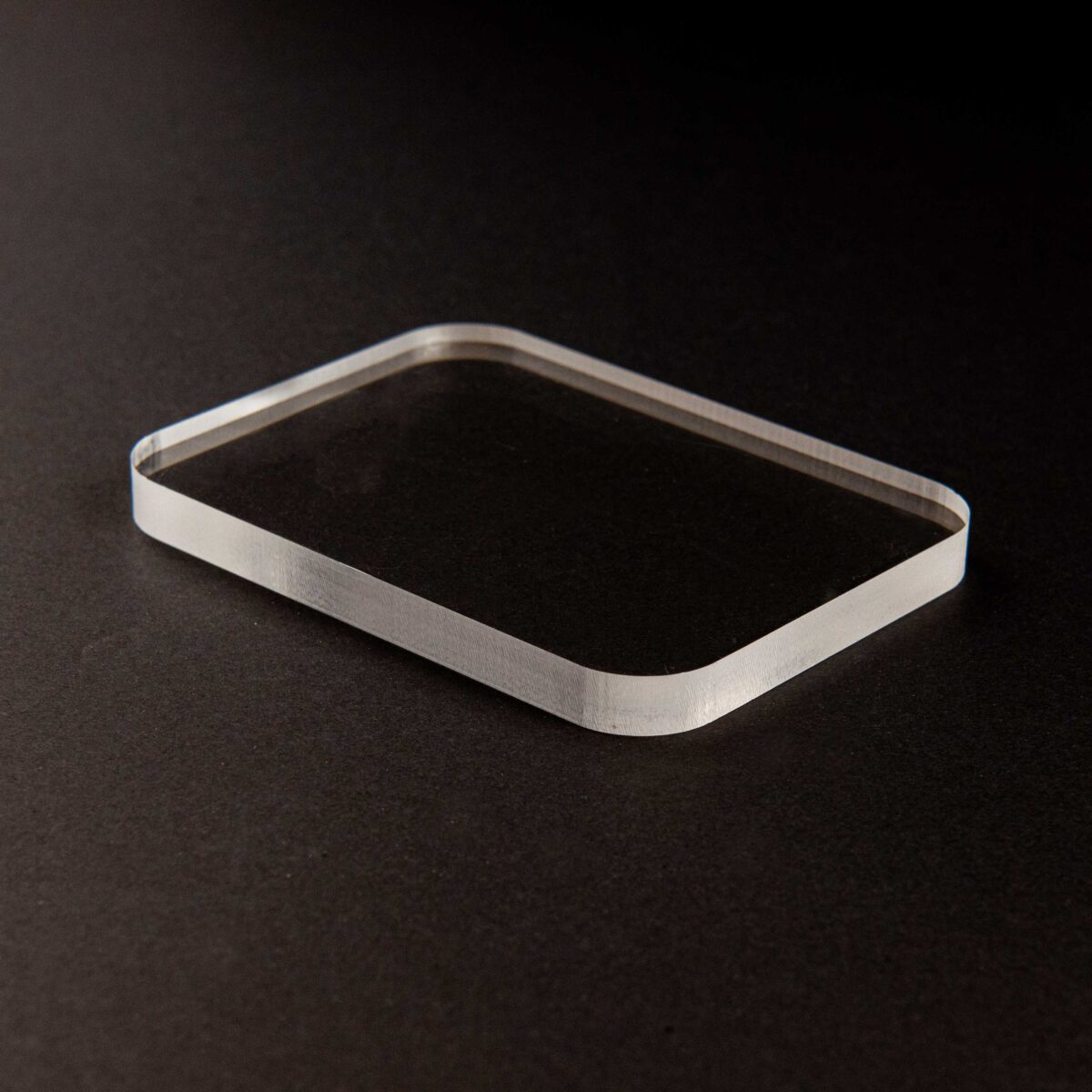

Glass has been a significant construction material for both residential and commercial spaces for many years. However, in light of the restrictions of glass in terms of use and durability, several options, like plastic, have been explored as suitable substitutes. This article covers transparent plastic, known as plexiglass sheets, and its effectiveness as a substitute for glass windows and other glass structures.

Glass has been a significant construction material for both residential and commercial spaces for many years. However, in light of the restrictions of glass in terms of use and durability, several options, like plastic, have been explored as suitable substitutes. This article covers transparent plastic, known as plexiglass sheets, and its effectiveness as a substitute for glass windows and other glass structures.

Despite boasting a durable and scratch-resistant surface,

Despite boasting a durable and scratch-resistant surface,

Glass is bulky, heavy, and extremely fragile.

Glass is bulky, heavy, and extremely fragile.