Are you in the e-commerce business and looking for a packaging material that will keep your products safe and secure during transit? Look no further—corrugated plastic sheets may be just what you need! This durable, cost-effective solution is not only lightweight but also recyclable, making it ideal for sustainable e-commerce packing. Plus, thanks to its waterproof nature and impact-resistance properties, corrugated plastic is increasingly becoming the go-to choice of many businesses when it comes to their shipping needs.

Are you in the e-commerce business and looking for a packaging material that will keep your products safe and secure during transit? Look no further—corrugated plastic sheets may be just what you need! This durable, cost-effective solution is not only lightweight but also recyclable, making it ideal for sustainable e-commerce packing. Plus, thanks to its waterproof nature and impact-resistance properties, corrugated plastic is increasingly becoming the go-to choice of many businesses when it comes to their shipping needs.

What Are the Challenges of E-Commerce Packaging?

While the rise of e-commerce has transformed the retail industry, it has also brought about a unique set of challenges for packaging. With more people shopping online, packaging demands have increased significantly. Not only must e-commerce packaging be visually appealing, but it also has to be sturdy enough to withstand handling and shipping. This poses a challenge for sustainability concerns, as many consumers are now environmentally conscious and demand that packaging be recyclable or reusable.

Resilience is key, as the packaging industry must adapt to new trends and technologies while also balancing cost concerns and consumer demands.

Advantages of Corrugated Plastic Sheets in E-Commerce Packaging

Let’s run through the many benefits of using corrugated plastic for e-commerce packaging.

Durability and Protection during Shipping

Corrugated plastic sheets are designed to be strong enough to withstand the rigors of long-distance shipping, while also providing cushioning to protect delicate items from damage. The sheets are also resistant to water, dust, and other contaminants, ensuring that your products arrive in perfect condition.

Versatility

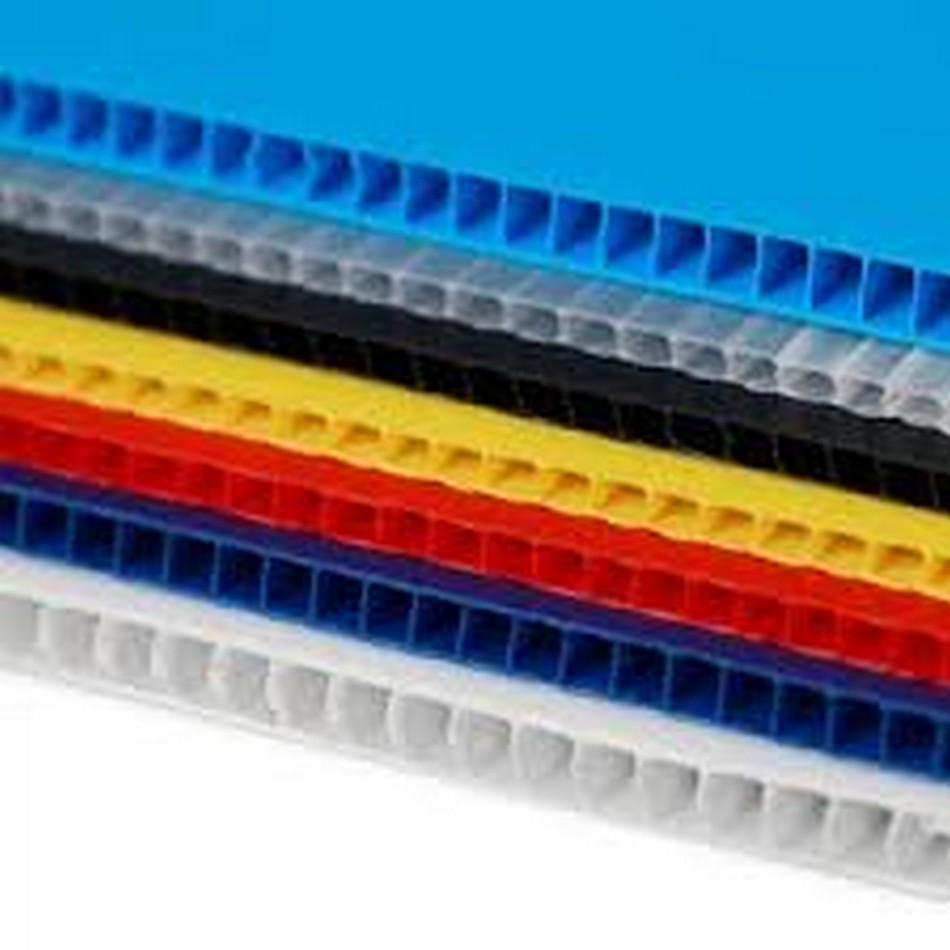

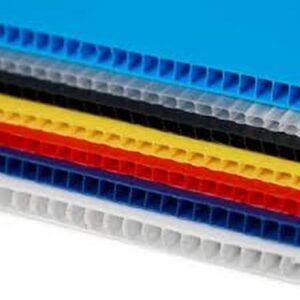

These sheets can be used for a variety of e-commerce packaging needs, including boxes, dividers, inserts, and wraps. They come in different sizes and thicknesses, making them suitable for a range of products from small electronics to large furniture pieces.

Lightweight Nature

The lightweight nature of corrugated plastic sheets means that they reduce the overall weight of the package without compromising on protection or durability. This makes it easier for customers to receive their orders quickly and efficiently.

Cost-Effective

Corrugated plastic offers excellent value for money compared to other packaging materials such as cardboard boxes or bubble wrap. Because they are lightweight, the sheets take up less space in storage and can be shipped more cheaply than heavier materials like cardboard boxes or foam packaging peanuts. Additionally, the durability of the material means that it is likely to last longer than other types of packaging materials, saving businesses money in the long run by reducing replacement costs.

Weatherproof

These weatherproof sheets can protect products from exposure to rain, snow, and other harsh weather conditions. This is especially important when shipping products to customers in areas with extreme weather conditions.

Customizability for Branding and Product Safety

Corrugated plastic can be printed with custom designs including company logos, product images, or other artwork, allowing businesses to create unique packaging solutions for their products. They can also be customized with inserts such as foam blocks or bubble wraps to provide extra cushioning for delicate items and increase customer satisfaction.

Sustainability and Reusability

Another advantage of corrugated plastic sheets is their sustainability compared to traditional cardboard boxes or foam inserts. The sheets are made from recycled materials and can be reused multiple times before needing to be disposed of, which helps reduce waste and minimize environmental impact.

Maximum Space Utilization

Corrugated plastic sheets provide maximum space utilization due to their flexibility and strength. The sheets can easily be cut into different shapes and sizes to fit snugly around the item being shipped without leaving any extra space in the package. This ensures that all items being shipped arrive safely at their destination without any additional costs associated with wasted space or damaged goods due to improper packing methods.

Specific Applications of Corrugated Plastic Sheets in E-Commerce

When it comes to e-commerce, the outer packaging of a product is just as important as the product itself. Corrugated plastic sheets have become increasingly popular for their ability to protect against impacts and weather conditions during shipping. These plastic sheets can be customized to fit any type of product, ensuring a tight, secure fit that minimizes the risk of damage.

Inner packaging solutions such as inserts and dividers are also crucial for ensuring safe delivery of fragile items. Customized compartments for multiple products can also simplify the shipping process, reducing the chance of things getting lost or damaged during transit.

Techniques and Customization Options for Corrugated Plastic E-Commerce Packaging

Die-cutting and shaping are two techniques used in corrugated plastic packaging that allow businesses to create tailored solutions for their products.

Die-cutting involves using a die press machine, which uses a sharp blade to cut the material into specific shapes or sizes. This technique can be used to create custom openings for items such as handles or straps, allowing for easy transport of products.

Shaping is another technique used in corrugated plastic packaging that involves using a heat source, such as a heated roller, to shape the material into desired forms. This technique can be used to create custom shapes for items such as point-of-purchase (POP) display boxes or containers that are specifically designed for certain products.

Businesses can also use printing techniques such as digital printing and flexographic printing to add images or other graphics to their packages. This allows businesses to create attractive and memorable packages that will help them to increase brand recognition.

Benefits for E-Commerce Businesses

Corrugated plastic sheets are an excellent choice for e-commerce businesses due to the cost savings they provide in shipping and returns.

What’s more, the use of these sheets can help to create a premium unboxing experience for customers, which can lead to increased customer satisfaction and loyalty.

And, in addition to being made from recycled plastics that would otherwise end up in landfills or oceans, the sheets require less energy to produce than materials such as cardboard and bubble wrap, making them a much more sustainable choice for e-commerce businesses looking to reduce their environmental impact.

Choose Canada Plastics and Belting Inc. for Your Corrugated Plastic Sheets in Toronto

Corrugated plastic for packaging offers the perfect combination of utility and cost-effectiveness that helps ensure low damage rates during shipping. This makes it a great option for online businesses looking for an efficient way to package products while staying ahead of industry modernizations.

If you want to learn more about how corrugated plastic sheets can improve your existing packaging solutions, then contact Canada Plastics and Belting Inc. today!

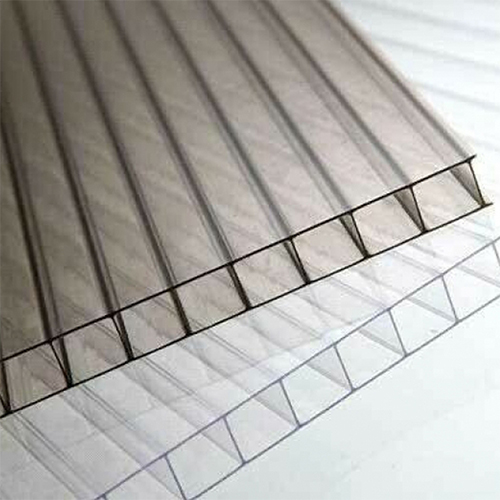

Corrugated plastic is a fluted plastic that is lightweight but rigid. With its big rectangular flutes running the entire length of it, the corrugated plastic is extruded and has a very long outdoor lifespan.

Corrugated plastic is a fluted plastic that is lightweight but rigid. With its big rectangular flutes running the entire length of it, the corrugated plastic is extruded and has a very long outdoor lifespan.

You’ve probably seen tons of lawn and real estate signs in your lifetime. Whether people are advertising their own businesses on their front lawns, selling their homes, or showing support for front line workers, there’s no doubt that these signs certainly have the ability to grab your attention as you’re walking or driving by.

You’ve probably seen tons of lawn and real estate signs in your lifetime. Whether people are advertising their own businesses on their front lawns, selling their homes, or showing support for front line workers, there’s no doubt that these signs certainly have the ability to grab your attention as you’re walking or driving by.