The high-speed packaging industry demands efficiency and reliability, and the conveyor belt is a key tool in its arsenal. These transport devices play a crucial role in ensuring products move seamlessly through various stages of packaging. Polytetrafluoroethylene (PTFE) conveyor belts, however, stand out as a transformative solution that is revolutionizing packaging operations. In this blog post, we’ll explore the various aspects of PTFE conveyor solutions and their profound impact on the packaging industry.

The high-speed packaging industry demands efficiency and reliability, and the conveyor belt is a key tool in its arsenal. These transport devices play a crucial role in ensuring products move seamlessly through various stages of packaging. Polytetrafluoroethylene (PTFE) conveyor belts, however, stand out as a transformative solution that is revolutionizing packaging operations. In this blog post, we’ll explore the various aspects of PTFE conveyor solutions and their profound impact on the packaging industry.

Overview of PTFE Conveyor Belt Usage in Packaging

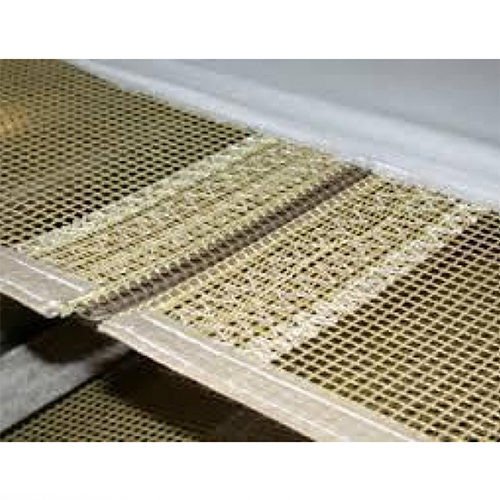

PTFE conveyor belts are a game-changer in the packaging industry, renowned for their exceptional properties and wide-ranging benefits. Made from PTFE material, also known as Teflon, these conveyor belts showcase unrivalled resistance to high temperatures, chemicals, and wear, making them ideal for demanding packaging environments.

PTFE belts are used at multiple stages of the packaging process, from product infeed to final packaging. Their versatility makes them an excellent choice for a variety of applications:

- Primary Packaging Lines: PTFE conveyor belts ensure smooth product movement and precise handling during initial packaging stages.

- Secondary Packaging Lines: These belts are ideal for bundling and wrapping, providing consistent performance.

- Integration with Inspection and Labelling Systems: PTFE belts facilitate seamless integration with automated inspection and labelling systems, ensuring quality control and accurate product information.

Operational Advantages of PTFE Conveyor Belts

A key reason for the growing popularity of PTFE conveyor belts in packaging is their numerous operational advantages:

Enhanced Speed & Precision

One of the standout features of PTFE belts is their low friction coefficient. This allows for smoother product movement, supporting high-speed packaging lines and precise product handling. The result is increased throughput and reduced risk of product damage.

Reduced Downtime

PTFE belts are easy to clean and require minimal maintenance compared to traditional belts. This significantly reduces downtime for cleaning and maintenance, keeping packaging lines running efficiently and reducing operational costs.

Improved Product Release

The non-stick properties of PTFE prevent product buildup on the conveyor belt, ensuring smooth product release. This is particularly beneficial in packaging processes where residue can cause significant delays and quality issues.

Temperature Resistance

PTFE belts can withstand a wide temperature range, making them suitable for various packaging processes involving heat or cold. Whether it’s sealing, freezing, or cooking, PTFE conveyor belts maintain their integrity and performance.

Sustainability Impact of PTFE Conveyor Belts

In addition to their operational benefits, PTFE conveyor belts contribute positively to the sustainability goals of the packaging industry.

Durability & Longevity

PTFE belts are known for their exceptional durability, reducing the need for frequent replacements. This longevity minimizes waste and contributes to more sustainable packaging practices.

Energy Efficiency

The low friction of PTFE belts translates to less energy consumption for conveyor operation. This efficiency not only reduces operational costs but also supports environmentally friendly practices by lowering the overall energy footprint.

Recyclability

At the end of their lifespan, PTFE belts can be recycled, further enhancing their sustainability credentials. This recyclability aligns with the growing emphasis on circular economy principles within the packaging industry.

Why Choose Canada Plastics and Belting Inc. for Your PTFE Conveyor Belt Needs?

Canada Plastics and Belting Inc. is a leading supplier of high-quality PTFE mesh conveyor belts in Toronto. We are committed to providing innovative and sustainable solutions tailored to the needs of the packaging industry. With a focus on quality and customer satisfaction, we ensure that your packaging operations achieve operational excellence and sustainability goals. Contact us today to begin transforming your packaging processes!

Conveyor belts are made of a variety of materials including metal, rubber, fabric, thermoplastics, and leather.

Conveyor belts are made of a variety of materials including metal, rubber, fabric, thermoplastics, and leather.