Polycarbonate sheets are clear sheets that are made with thermoplastic polymers that contain plastic material and are combined with carbonate groups to give rise to a strong, impact-resistant sheet. Below, we explore the benefits of using polycarbonate sheets for security and safety applications.

Features of Polycarbonate Sheets

Polycarbonate sheets have some peculiar features that make them versatile and a preferred choice in several industries. Some properties of polycarbonate sheets include:

High strength

Polycarbonate can be termed as unbreakable because of its high-strength features that can withstand temperatures as high as 1400C and temperatures as low as -200C. Polycarbonate polymers also have a density of 1.2 – 1.22g/dm3 making them very strong and impact resistant.

Refractive Index

The refractive index of polycarbonate is 1.548, and it has amazing optical features that allow it to be used in several optical devices and applications.

Resistance to Chemicals

Polycarbonate is resistant to reactions by certain chemicals like aliphatic hydrocarbons, diluted acids, and alcohols. It also shows moderate resistance to substances like grease and oil. However, polycarbonates are susceptible to attack by diluted alkalis and halogenated and aromatic hydrocarbons.

Transmittance

Polycarbonate can transmit about 90% of light, even as well as glass. This feature allows it to be applied in various forms.

Applications of Polycarbonate

There are countless applications of polycarbonate sheets in various industries, such as:

Appliances

Polycarbonate sheets are used in the manufacture of various appliances such as refrigerators, washing machines, air conditioners, hair dryers, food warmers, and so much more. This is because of their ability to be easily shaped, as well as their beautiful finish that makes appliances stand out.

Medical Applications

Polycarbonate sheets also have medical applications due to features like clarity, heat resistance, resistance to chemicals, and high strength. They are used in the manufacturing of medical instruments and appliances

Food Packaging

Polycarbonate can be used to make food packaging materials because it is heat and shatter resistant. It can be used for the manufacture of reusable food packages that are safe in microwaves.

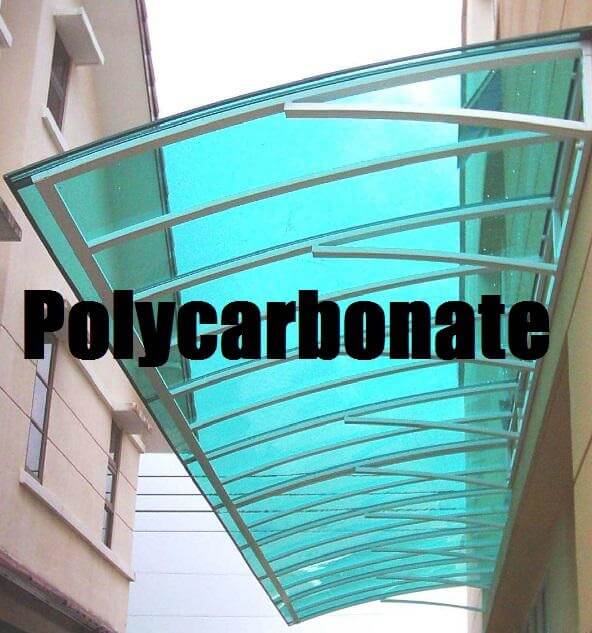

Building and Construction

Polycarbonate is used as a good alternative to glass in the building and construction industry. It can be used for different types of buildings and is preferred for its impact resistance, light transmission, and its resistance to UV rays

Cars and Other Automobiles

Polycarbonate is very essential in the manufacture of cars and other automobiles, mainly for its lightweight and impact resistant properties. Also, its clarity and heat resistance make it a good choice for headlamps and lenses.

How Can Polycarbonates Improve Security and Safety?

Here are some ways in which polycarbonate sheets can improve security and safety:

Security of Property

Polycarbonate sheets can be used in the manufacturing of certain property protection and security features, such as anti-burglary screens. Although these screens are not designed to prevent entry into a property completely, the high strength and impact-resistant properties of polycarbonate sheets make them difficult to break through and can delay trespassers long enough for help to arrive. They can also be used for window glazes, window bars, and safety screens.

Protective Gear

Polycarbonate is used for safety equipment such as face shields, helmets, anti-riot shields, and many others. This protective gear can be used by law enforcement, as well as mechanical workers. The lightweight property of polycarbonate makes this equipment easy to wear or carry while its impact resistance and strength make it a good protective material from both force and certain chemical damage.

Protection Against Vandalism

Polycarbonate can be used to glaze surfaces that are prone to vandalism, such as schools, commercial buildings, bus stops, and even some residential areas. The anti-abrasive property of polycarbonate and its resistance to oils and grease makes it a good tool for protecting surfaces from vandalism and destruction.

Car and Transportation Safety

The lightweight property of polycarbonate makes it a favorite with car manufacturers to ensure optimum performance. However, polycarbonate offers a few other safety benefits for cars and transportation, such as clear, impact-resistant windshields that are easy to see through and make driving easy and also difficult to break into.

Means of transportation like cable cars or rail transport require the use of abrasion-resistant materials, and polycarbonate sheets can help reduce the need and cost of maintenance. Polycarbonate can also help with heat control within the vehicle with specific tint modifications added to its transmissive surfaces.

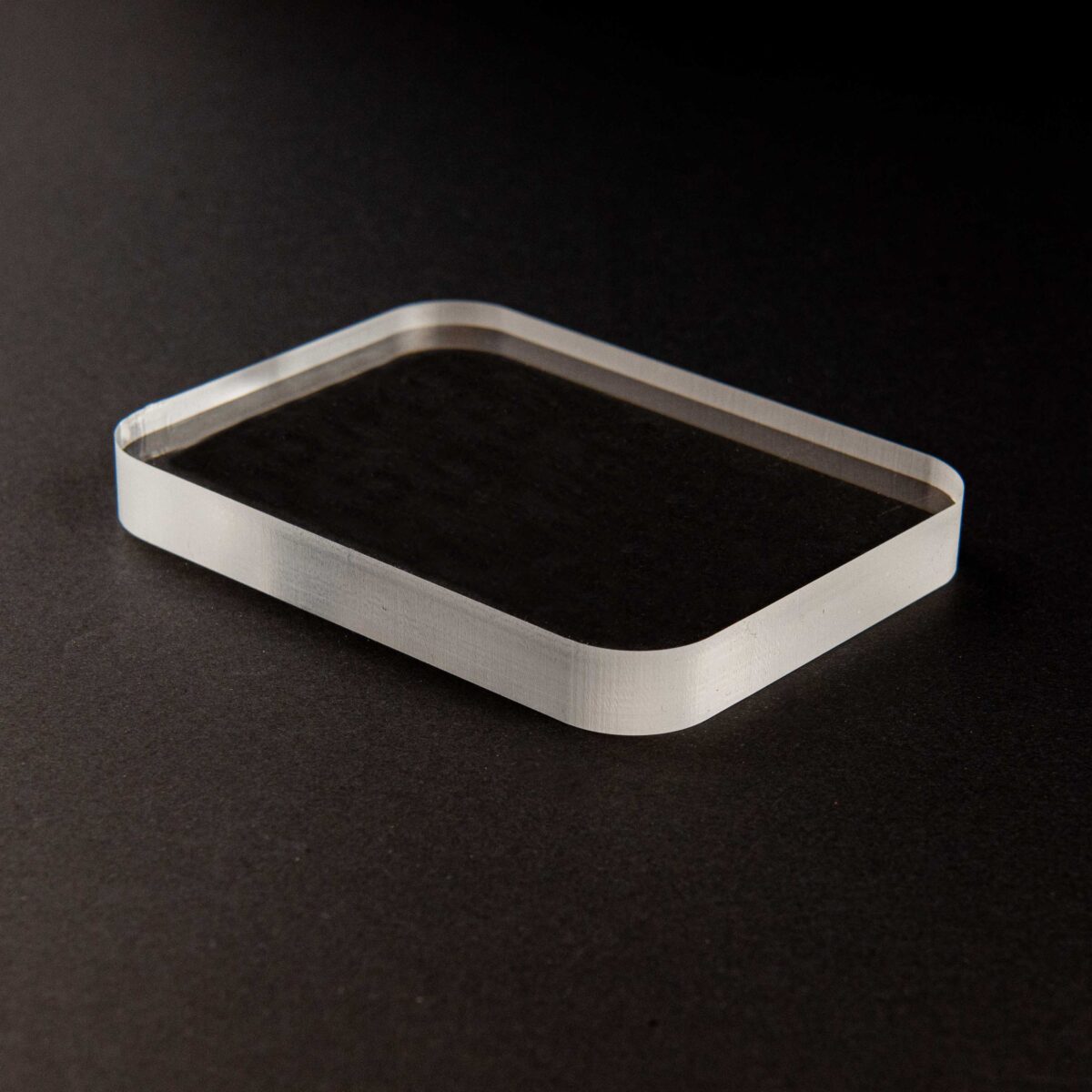

Bulletproof Windows

Polycarbonate is about 30 times stronger than acrylic and roughly 200 times stronger than glass, making it a good choice for protective surfaces. Layered polycarbonate sheets can be used for bulletproof windows that can absorb shot impact without shattering.

Polycarbonate vs. Glass: Which Is Better?

Here are some advantages of polycarbonate over glass:

Strength: Polycarbonate is stronger than glass and practically unbreakable, making it a preferred option for windows and windshields. Polycarbonate is also capable of withstanding harsh weather conditions.

Higher Resistance to Heat: Although glass has good heat resistance capacity, polycarbonate can withstand temperatures up to 470 degrees and even sudden heat bursts as high as 1,000 degrees without any damage or distortion to its structure.

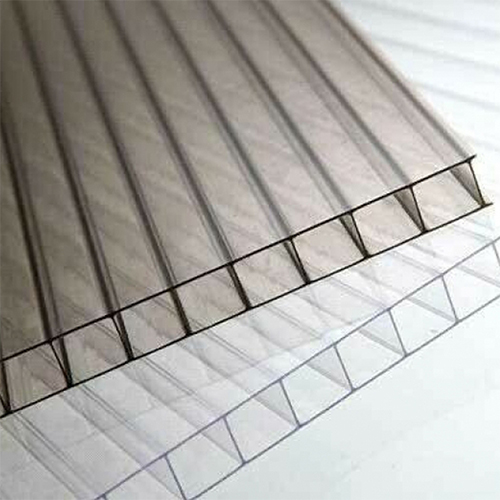

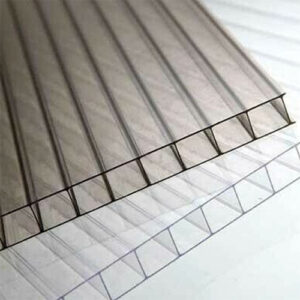

Better Heat Insulation: The heat insulation capacity of polycarbonate exceeds that of glass. Polycarbonate is a better insulator and more energy efficient in that it can help maintain and regulate the temperature of a space and reduce energy consumption.

More Durable: Polycarbonate is stronger and more impact-resistant than glass and is able to withstand more damaging impact than glass. This makes it a more durable option for building projects.

Easier to Install and Use: Polycarbonate is light and easy to work with. It can easily be shaped and attached to the surfaces required, unlike glass. On some occasions, polycarbonate is used as a glaze for glass windows for extra strength and flair.

Canada Plastics & Belting Inc. offers an extensive range of polycarbonate sheets for greenhouses, roofing panels, and other building projects. Our products are fully customizable to suit your project needs and are available in different thicknesses, colour options, and textures. Contact us today to learn more.

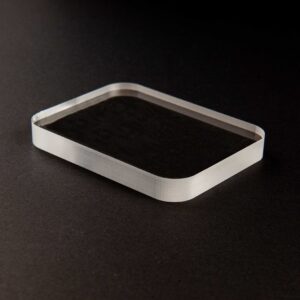

Polycarbonate sheet

Polycarbonate sheet

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

There are many different types of

There are many different types of

Polycarbonate corrugated panels are a favourite building and construction accessory for various commercial projects and homeowners engaged in DIY projects. Our A-1 quality polycarbonate corrugated panels in Canada are both lightweight and firm, which deliver phenomenal strength, flexibility, weather resistance, and light transmissions. As a noncorrosive industrial structural roofing and siding option, its ability to withstand high impact and function well under a broad temperature spectrum is favoured.

Polycarbonate corrugated panels are a favourite building and construction accessory for various commercial projects and homeowners engaged in DIY projects. Our A-1 quality polycarbonate corrugated panels in Canada are both lightweight and firm, which deliver phenomenal strength, flexibility, weather resistance, and light transmissions. As a noncorrosive industrial structural roofing and siding option, its ability to withstand high impact and function well under a broad temperature spectrum is favoured.