Clean Floors and Happy Workplace with GloFloExperience clean floors and create a happy workplace atmosphere with GloFlo’s exceptional cleaning agents.

Clean Floors and Happy Workplace with GloFloExperience clean floors and create a happy workplace atmosphere with GloFlo’s exceptional cleaning agents.

Our extensive range of high-quality cleaning products is designed to tackle any cleaning challenge you may encounter. From stubborn stains to hard-to-reach corners, GloFlo has the perfect solution. We offer a diverse selection of cleaning agents, and our dedicated team also provides valuable cleaning advice and guidance.

We take pride in sharing our expertise, ensuring you understand the most effective methods for applying our agents to achieve optimal results.GloFlo’s commitment to environmentally friendly practices means our cleaning agents are safe for both your workplace and the planet. You can trust that our products will leave your floors spotless without compromising sustainability.

Tips and Tricks for Getting Industrial Floor Cleaned

Maintaining clean industrial floors is crucial for ensuring a safe and productive work environment. However, cleaning large industrial spaces can be a challenging task. To help you achieve spotless floors, we’ve gathered some valuable tips and tricks for effective industrial floor cleaning.

-

Preparing the area:

-

- Clear the floor of any obstacles or debris.

- Block off the area to prevent foot traffic during cleaning.

-

Selecting the right cleaning agents:

-

- Choose cleaning agents specifically formulated for industrial floors.

- Consider factors such as floor type, stains, and level of dirt accumulation.

-

Using appropriate equipment:

-

- Utilize industrial-grade floor scrubbers, sweepers, or pressure washers for efficient cleaning.

- Ensure the equipment is properly maintained and adjusted for optimal performance.

-

Following proper cleaning techniques:

-

- Start by sweeping or dry mopping to remove loose dirt and dust.

- Apply the cleaning agent as directed, using suitable dilution ratios.

- Scrub the floor thoroughly, paying attention to high-traffic areas and stubborn stains.

-

Implementing regular maintenance:

-

- Establish a cleaning schedule to prevent dirt buildup.

- Conduct routine inspections to identify any maintenance or repair needs.

By following these tips and tricks, you can achieve clean and well-maintained industrial floors, promoting a safe and productive working environment.

How Industrial Floor Cleaners Can Improve Your Business?

Industrial floor cleanliness plays a vital role in the success of any business. Clean, well-maintained floors enhance the overall aesthetics and offer several benefits that positively impact your business operations. Discover how industrial floor cleaners can improve your business in the following ways:

-

Enhanced Safety:

- Regular cleaning removes spills, debris, and potential hazards, reducing the risk of accidents or injuries in the workplace.

- Clean floors contribute to improved traction and prevent slips and falls, ensuring a safer environment for employees and visitors.

-

Increased Productivity:

- Clean, organized workspaces create a more focused and efficient atmosphere.

- Employees can navigate easily, locate equipment, and perform tasks without interruptions, boosting productivity and workflow.

-

Enhanced Brand Image:

- A clean and well-maintained facility reflects professionalism, attention to detail, and care for customers.

- It leaves a positive impression on clients, visitors, and potential partners, enhancing your brand image and reputation.

-

Extended Floor Lifespan:

- Regular cleaning and maintenance help prevent dirt, dust, and contaminants from accumulating and causing damage to the flooring materials.

- By extending the lifespan of your floors, you save on costly repairs or replacements, contributing to long-term cost savings.

-

Healthier Environment:

- Clean floors minimize dust, allergens, and pollutants, improving indoor air quality. This promotes a healthier work environment, reduces sick leave, and enhances employee well-being.

Investing in professional industrial floor cleaners can significantly improve your business by providing a clean, safe, and productive workspace.

The Advantages of Investing in Industrial Floor Cleaner Liquid by GloFlo

Investing in GloFlo’s industrial floor cleaner liquid offers a range of advantages for your business. Their specialized formulas provide superior cleaning performance, effectively removing tough stains and grime. The concentrated nature of the liquid ensures cost-effectiveness, as it lasts longer and reduces the need for frequent purchases.

By using GloFlo’s floor cleaner liquid, you can save time on cleaning tasks, allowing your employees to focus on core responsibilities and increasing overall productivity. Additionally, GloFlo offers eco-friendly options, prioritizing sustainability and minimizing environmental impact. Their expert guidance ensures proper application and optimal results, helping you maintain clean and well-maintained industrial floors.

FAQS

-

How can I deep clean my floors?

Thoroughly mop with a suitable cleaner and scrubbing technique.

-

Which floor cleaner liquid in Pakistan is the best?

GloFlo brings you the best floor cleaner liquid in Pakistan.

Conclusion

GloFlo’s industrial floor cleaning solutions, you can achieve clean floors, creating a happy and productive workplace. Experience the transformative power of GloFlo and elevate your business today. Contact us for a consultation and unleash the potential of clean floors!

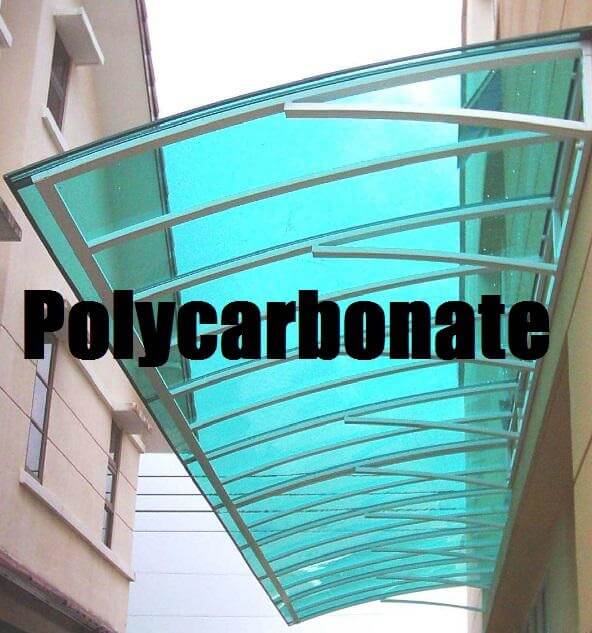

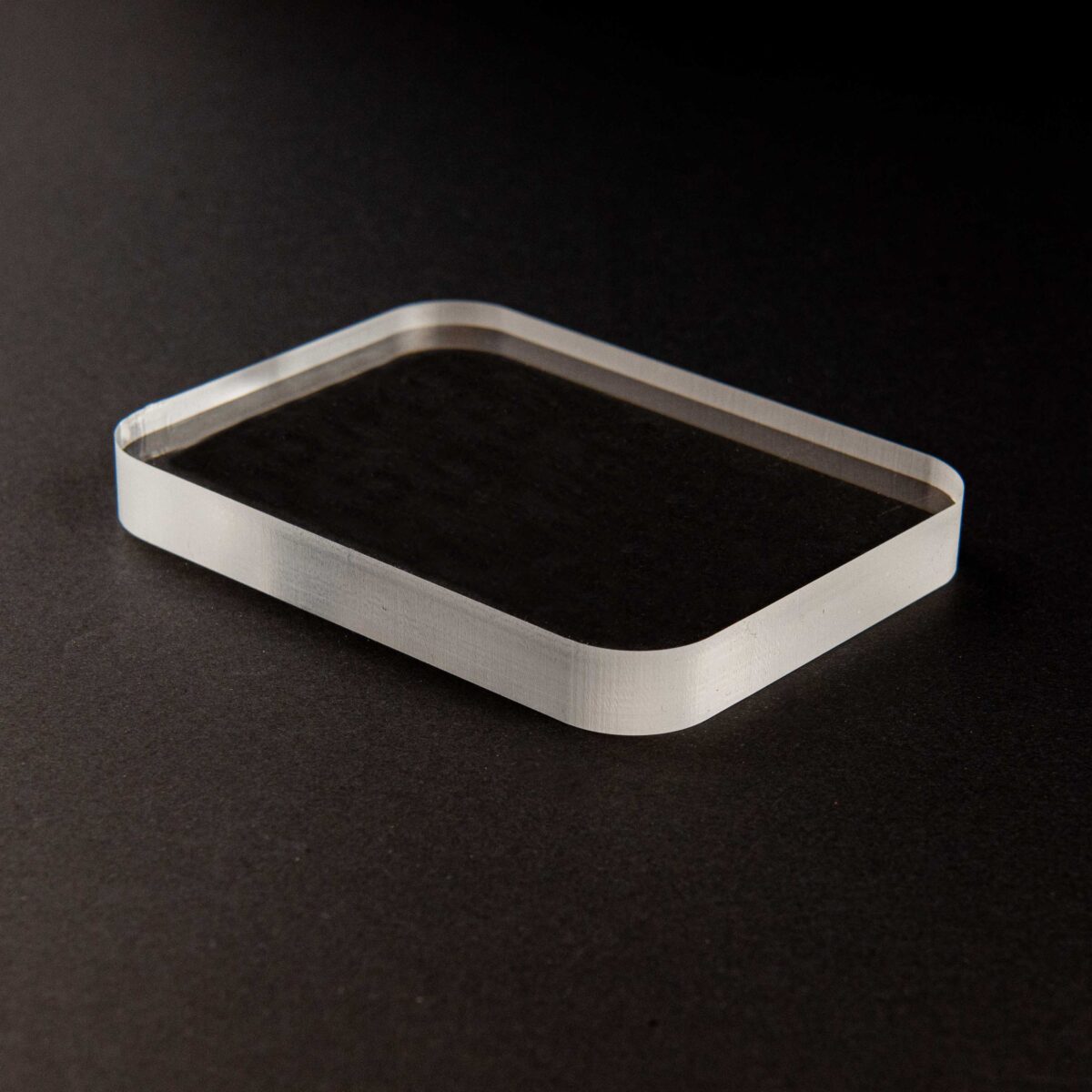

Polycarbonate sheet

Polycarbonate sheet

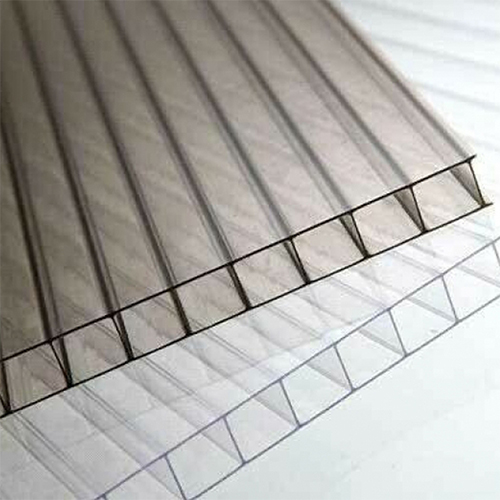

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

There are many different types of

There are many different types of