Self-service dining establishments like buffets along with a handful of fast food restaurant chains (a certain well-known sandwich shop comes to mind) have been using sneeze guards for decades to prevent bacterial and viral contamination in their food. Sneeze guards have been a staple in a number of restaurants across North America since 1958 when they were initially introduced by restauranteur Johnny Garneau, who was a self-proclaimed germaphobe in his own right.

Self-service dining establishments like buffets along with a handful of fast food restaurant chains (a certain well-known sandwich shop comes to mind) have been using sneeze guards for decades to prevent bacterial and viral contamination in their food. Sneeze guards have been a staple in a number of restaurants across North America since 1958 when they were initially introduced by restauranteur Johnny Garneau, who was a self-proclaimed germaphobe in his own right.

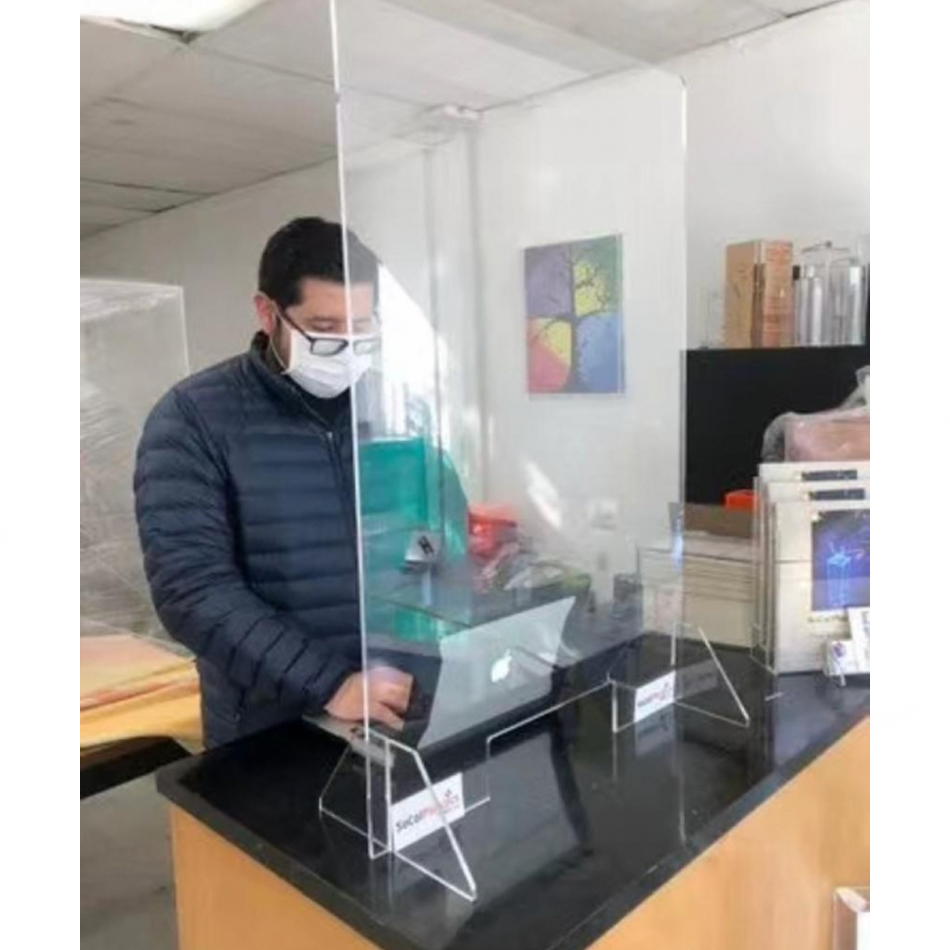

Amidst the COVID-19 pandemic, an increasing number of restaurant owners have adopted the use of sneeze guards not just to protect food behind the counter from contaminants but to also encourage physical distancing between customers dining indoors. Restaurant sneeze guards are FDA-approved, which means they’ve been thoroughly tested and proven to help prevent the spread of germs in enclosed spaces. Read on to learn more about the efficacy and usefulness of sneeze guards for restaurants and factors business owners should consider when installing them.

Why Sneeze Guards Are Recommended in Restaurants

By design, sneeze guards protect food preparation areas from being contaminated with airborne bacteria, viruses, and droplets that can spread disease. The concept of installing sneeze guards for restaurants is nothing new, but it’s become increasingly popular thanks in large part to the COVID-19 pandemic. In an effort to make customers feel more comfortable dining at their favourite local eateries again, restaurant owners have to take special precautions to prevent the spread of disease.

Federal regulations have mandated for years that specific eating establishments like buffets and any restaurant where food preparation takes place front of house are required to install restaurant sneeze guards to protect the general public. Restaurant dividers for COVID-19 must follow a unique set of regulations in order to be deemed effective and in compliance with the rules.

Factors such as sneeze guard thickness, material used (typically a restaurant-grade type of plastic), height, and durability are all taken into consideration. Although they’re built to withstand all kinds of usage and various public environments, sneeze guards can still be susceptible to some damages and should be replaced or repaired at the first sight of cracking.

Are Sneeze Guards Required in Self-Service Fast Food Establishments?

Yes, sneeze guards are required in self-service fast food establishments to maintain high food sanitation standards. This has always been the case, long before the pandemic.

Sneeze guards for restaurants are becoming increasingly ubiquitous in the food and hospitality industry. Even full service restaurants are seeing the value of installing them throughout their establishments to encourage physical distancing between customers and encourage more people to take advantage of dine-in options.

Restauranteurs are devoted to maintaining the high quality of their food and customer safety and satisfaction has been top of mind long before the beginning of the pandemic.

Visibility is of absolute importance when it comes to choosing sneeze guards for your restaurant. Customers need to be able to clearly see the ingredients being used behind the counter, especially if you own the type of establishment that requires them to choose various toppings and dishes from a hot table, food prep area, or buffet.

Important Factors to Consider when Choosing Sneeze Guards for Your Restaurants

Sneeze guards come in a variety of standard shapes and sizes, but they can also be customized according to the parameters of your restaurant. Every restaurant is different and therefore has unique physical restrictions. Eateries vary in size, layout, and customer capacity. These are all important factors that should be taken into consideration when selecting specific types of sneeze guards for your restaurant.

Additionally, sneeze guards should be clear to make total visibility and transparency possible. Whether you’re planning on installing table-mounted or freestanding sneeze guard barriers in your restaurant, the following considerations are paramount when deciding on a specific design.

Easy Installation

Depending on your preferences, you can choose to either permanently drill sneeze guards into various surfaces such as countertops and tables throughout your restaurant or you can choose a more temporary and portable options. Free standing sneeze guard barrier suppliers work with manufacturers to design and produce restaurant dividers that come with a stable and heavy base to keep them in place without requiring any permanent drilling or downtime. These sneeze guards can easily be moved around your restaurant as needed and can even be disassembled for easy and space-efficient storage.

Adaptability

“Adaptability” has become a major buzzword over the course of the pandemic. Businesses across all sectors have been forced to adapt in various capacities to the constantly changing mandates all in the name of protecting and preserving public health standards. Sneeze guard selection and customization is included in the need for perpetual adaptability. Mounting poles, barriers, and other hardware need to be adaptable and adjustable enough to fit perfectly with various surfaces and structures. As the rules and regulations are updated, restaurant workers should be able to move and adjust freestanding or mounted barriers with ease to better accommodate new health and safety standards that may emerge over time while maintaining the comfort and safety requirements of customers and employees.

Durability

In addition to excellent adaptability, the sneeze guards you select for your restaurant should be extremely durable. After all, just think of all of the people and things they’ll most likely be exposed to. Between people bumping up against them, being moved from one location to another, and all of the cleaning and sanitation agents they’ll be exposed to, sneeze guards endure a lot of usage and should be fully capable of handling anything that’s thrown at them.

Affordability

Sneeze guards are always on the job and that means that they may need to be repaired or replaced from time to time due to minor or major damages. Wear and tear such as scratches or cracking over time are inevitable. And, depending on the size, quantity, and customization required, some sneeze guard suppliers in Toronto might charge more than others.

Compatibility with Your Current Setup

Lastly, you need to consider whether sneeze guards are fully compatible with your current restaurant layout. Sneeze guards can be fully customized to fit the exact dimensions of your space and the specific surfaces being covered, so be sure to take exact measurements before placing your order.

Freestanding Sneeze Guard Suppliers in Toronto

Whether you’re looking for mounted or freestanding sneeze guard suppliers in Toronto, Canada Plastics & Belting Inc. has just what you need for your restaurant. We have an extensive inventory of industrial, commercial, and restaurant-grade plastic sneeze guards with a variety of hardware options that are fully customizable according to your specifications. Contact us today to learn more or visit our showroom in Scarborough!

Most people associate Teflon with cookware. Yes, it’s that non-stick coating that prevents food from sticking to your pans and allows you to use less butter or oil when you’re cooking. But it’s so much more than that. Did you know that Teflon conveyor belts are used in a number of industrial and commercial applications? Keep reading to learn about the different applications and advantages of Teflon conveyor belts.

Most people associate Teflon with cookware. Yes, it’s that non-stick coating that prevents food from sticking to your pans and allows you to use less butter or oil when you’re cooking. But it’s so much more than that. Did you know that Teflon conveyor belts are used in a number of industrial and commercial applications? Keep reading to learn about the different applications and advantages of Teflon conveyor belts.

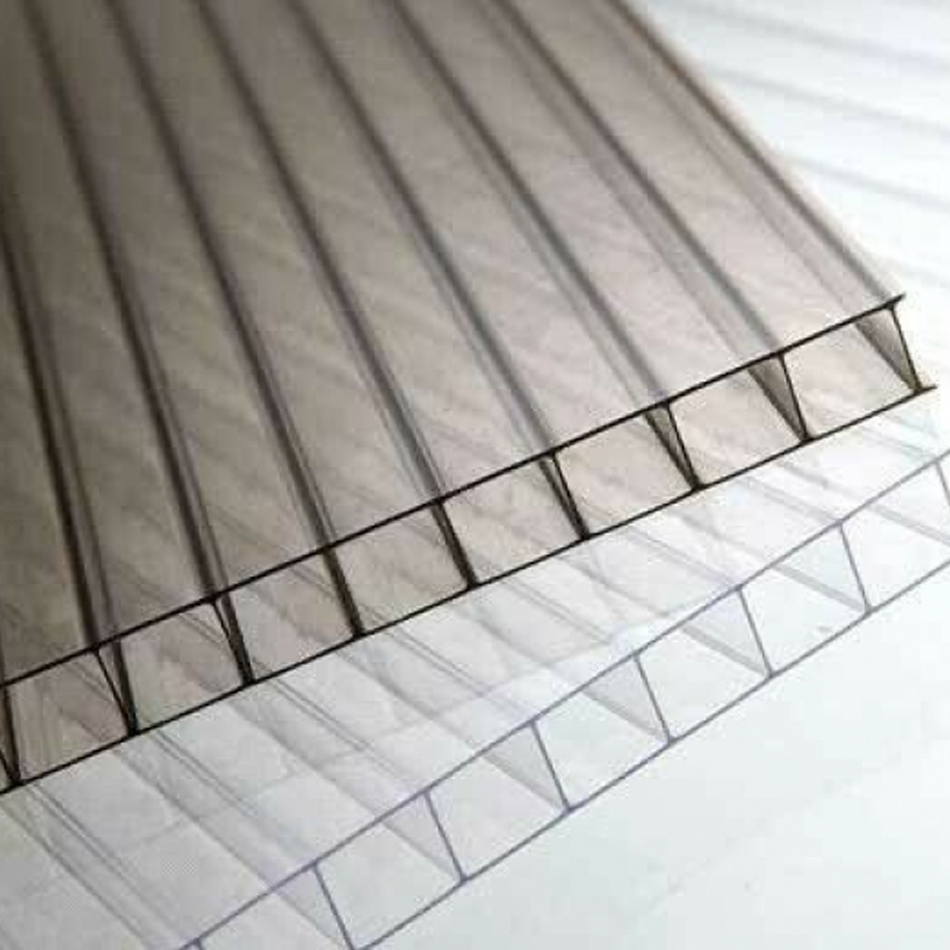

Over the past several years, polycarbonate has grown immensely in popularity, often serving as a replacement for glass and other plastic composites for various applications. Polycarbonate multiwall sheets for greenhouses are especially making a big impression on the commercial and residential gardening industries. Greenhouse polycarbonate sheets come in a variety of configurations. Choosing the right

Over the past several years, polycarbonate has grown immensely in popularity, often serving as a replacement for glass and other plastic composites for various applications. Polycarbonate multiwall sheets for greenhouses are especially making a big impression on the commercial and residential gardening industries. Greenhouse polycarbonate sheets come in a variety of configurations. Choosing the right

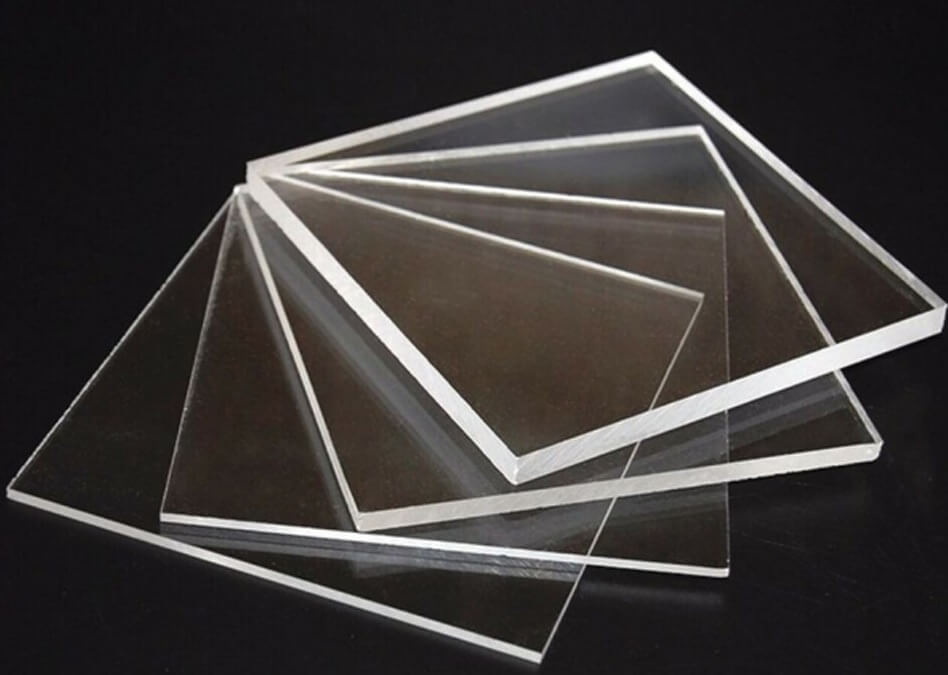

Acrylic is one of the most versatile building materials in the world. It can be used for a wide range of applications across numerous industries, but its main purpose is to act as a more affordable and durable replacement for glass. Hence, acrylic has many of the same properties of glass including appearance and transparency options. The main exception is that acrylic is virtually unbreakable, can last a very long time, and is easier to maintain.

Acrylic is one of the most versatile building materials in the world. It can be used for a wide range of applications across numerous industries, but its main purpose is to act as a more affordable and durable replacement for glass. Hence, acrylic has many of the same properties of glass including appearance and transparency options. The main exception is that acrylic is virtually unbreakable, can last a very long time, and is easier to maintain.

Plastic is a durable, light weight, cheap and easily modified material and has been extensively used in our daily lives.

Plastic is a durable, light weight, cheap and easily modified material and has been extensively used in our daily lives.

Multiwall polycarbonate sheets are quickly becoming the go-to material for a lot of indoor, outdoor, commercial, and industrial construction projects and applications. In addition to being extremely lightweight and durable,

Multiwall polycarbonate sheets are quickly becoming the go-to material for a lot of indoor, outdoor, commercial, and industrial construction projects and applications. In addition to being extremely lightweight and durable,

Self-service dining establishments like buffets along with a handful of fast food restaurant chains (a certain well-known sandwich shop comes to mind) have been using sneeze guards for decades to prevent bacterial and viral contamination in their food.

Self-service dining establishments like buffets along with a handful of fast food restaurant chains (a certain well-known sandwich shop comes to mind) have been using sneeze guards for decades to prevent bacterial and viral contamination in their food.