Glass has been a significant construction material for both residential and commercial spaces for many years. However, in light of the restrictions of glass in terms of use and durability, several options, like plastic, have been explored as suitable substitutes. This article covers transparent plastic, known as plexiglass sheets, and its effectiveness as a substitute for glass windows and other glass structures.

Glass has been a significant construction material for both residential and commercial spaces for many years. However, in light of the restrictions of glass in terms of use and durability, several options, like plastic, have been explored as suitable substitutes. This article covers transparent plastic, known as plexiglass sheets, and its effectiveness as a substitute for glass windows and other glass structures.

What Is a Plexiglass Window?

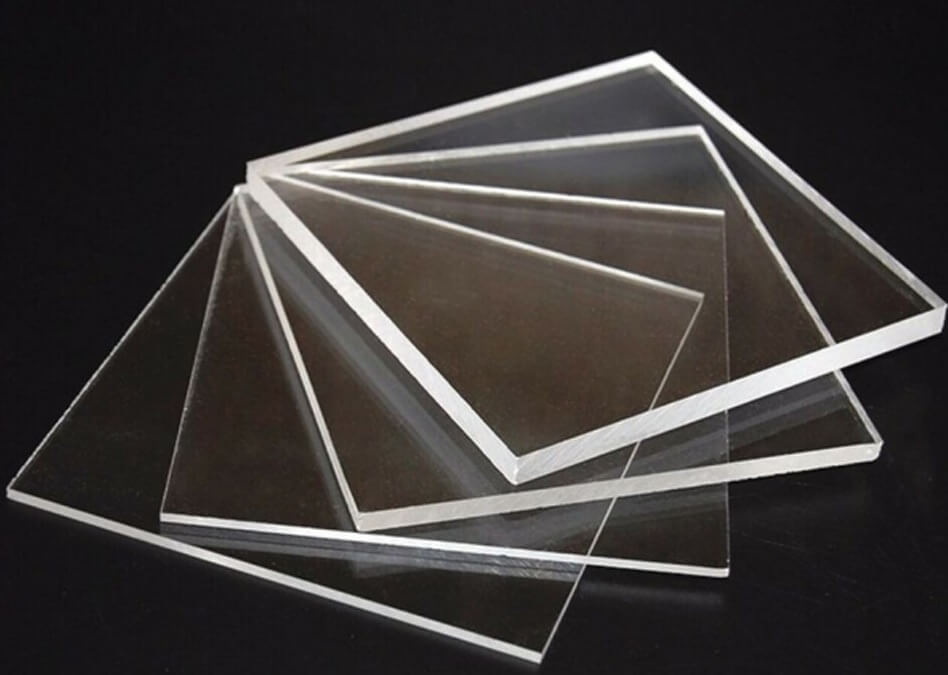

A plexiglass window is a window made from plexiglass which is a clear plastic that is made from polymethyl methacrylate. Plexiglass is an efficient substitute for glass mainly for its sturdiness and resilience to damage. Despite its similarity in terms of appearance and strength, plexiglass is not the same as glass as it’s made from acrylic.

Is a Plexiglass Window as Clear as a Glass Window?

Several factors can affect the clarity of glass, such as the method of production, the adhesive layer of the glass window, and even the thickness of the window. Although glass windows reflect light easily, they are not entirely transparent, and the thicker they are, the less clear they become.

On the other hand, Plexiglass windows can maintain 100% light reflection no matter how thick the window is. Plexiglass windows can be clearer than glass windows as they are entirely transparent.

How Thick Should Plexiglass Be for a Window?

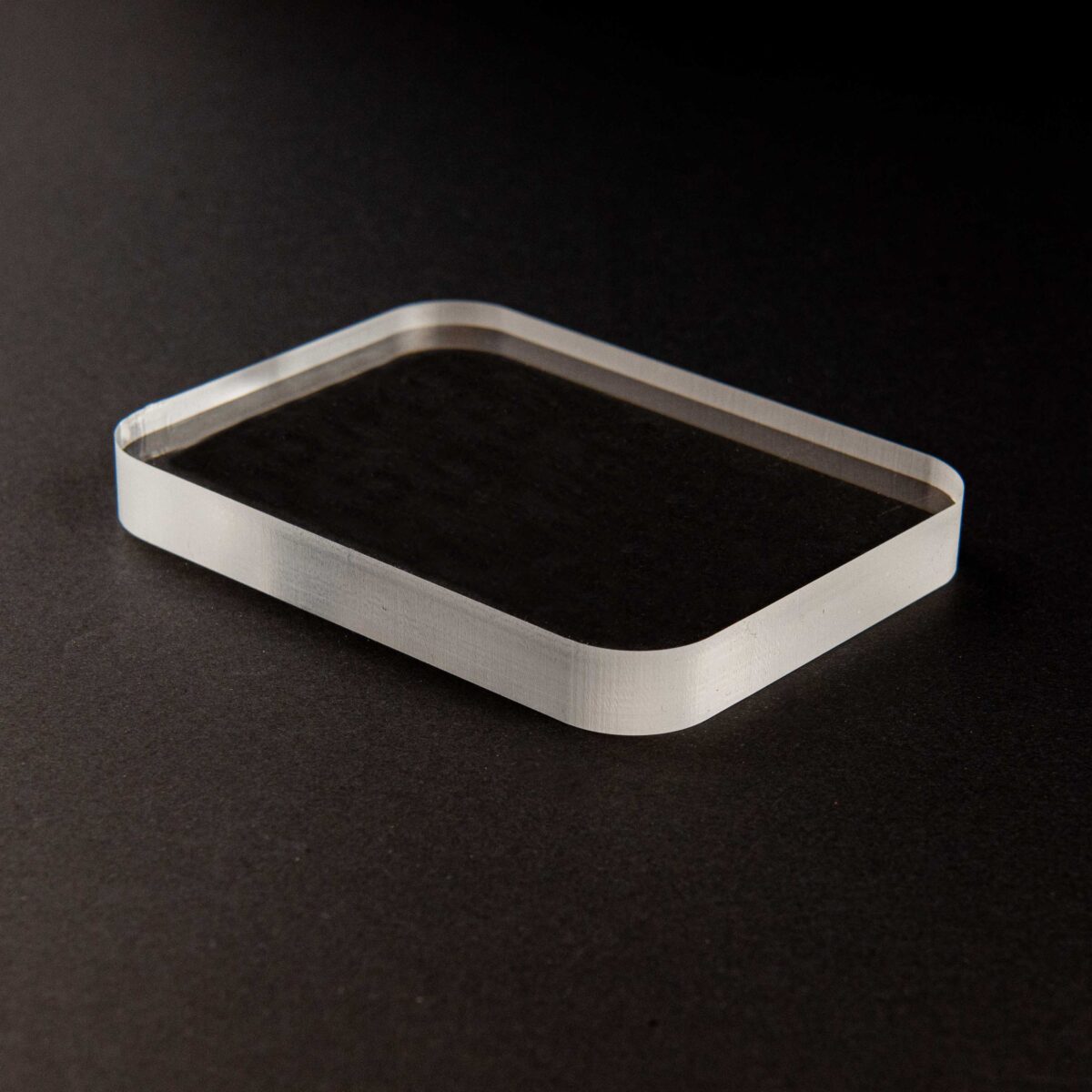

Plexiglass windows can measure as much as 1.25 inches in thickness; however, the thickness of plexiglass windows depends on several factors, such as the size of the window to be installed, the type of building, and the climate of the environment.

Small buildings in simple structures with mild weather conditions do not require thick plexiglass windows. On the other hand, in large buildings with bigger windows or structures with harsh weather conditions, more expansive plexiglass windows are sturdier and provide more support.

Does Plexiglass Turn Yellow in the Sun?

Exposure to intense radiation or prolonged exposure to sunlight can cause the glass’s yellowing due to arsenic. This can be noticed in very old car headlights or even windows. However, plexiglass is known for its durability, even in sunlight.

Unlike other types of plastics like PE that degrades or are discoloured with prolonged exposure to sunlight, plexiglass is made of acrylic sheets capable of withstanding the radiation produced by sunlight and retaining their appearance for a very long time. Therefore, users don’t have to worry about the discoloration or yellowing of their plexiglass windows compared to using glass windows.

Reasons to Use Plexiglass for Windows

Some reasons to embrace the use of plexiglass sheets for windows include the following:

1. Cost-effective: Using plexiglass for windows is cheaper and more cost-effective than using glass. This is because the production of plexiglass requires less energy and raw materials. Also, compared to glass, plexiglass is easier and cheaper to transport from one place to another because they are lighter in weight.

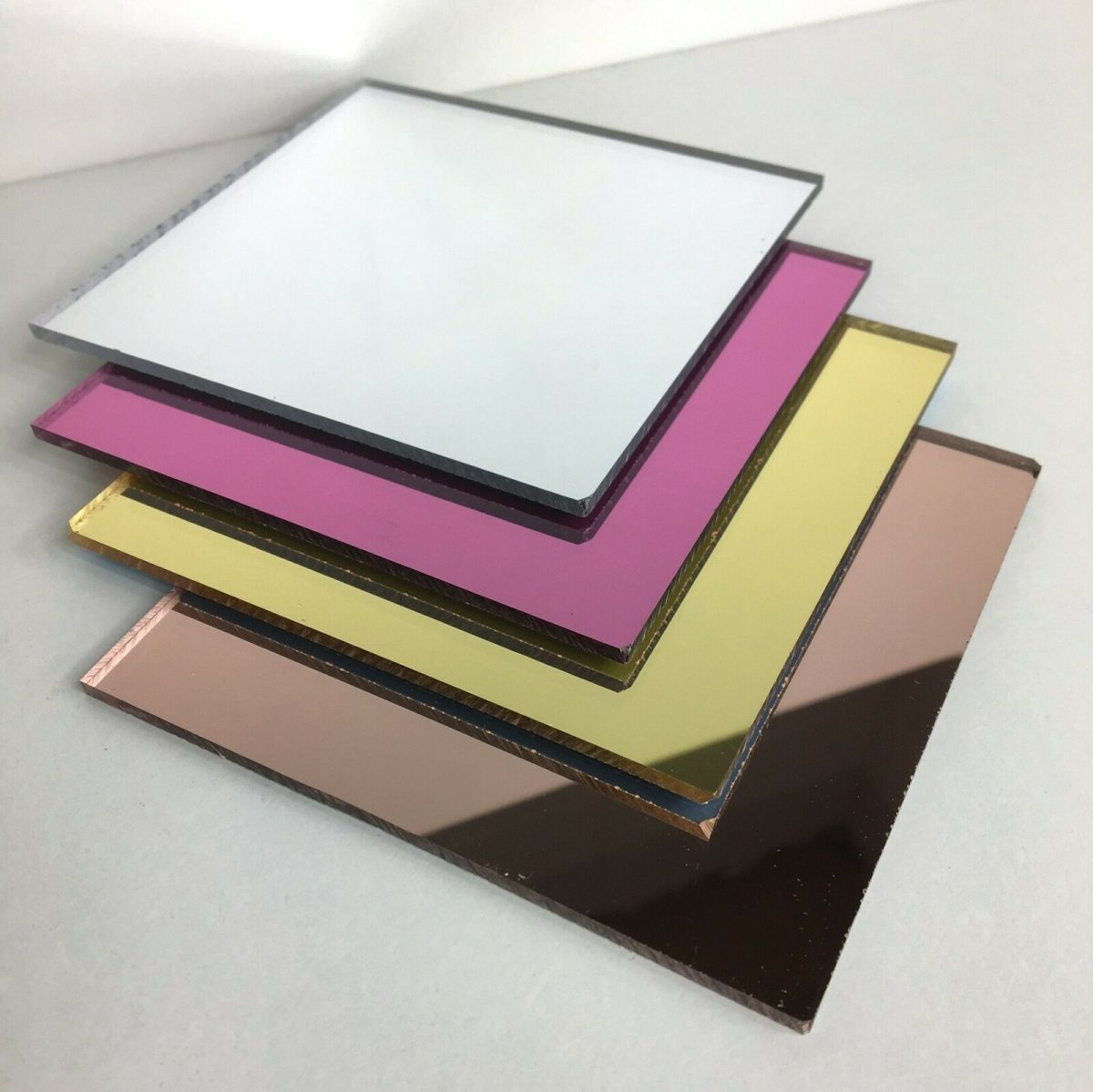

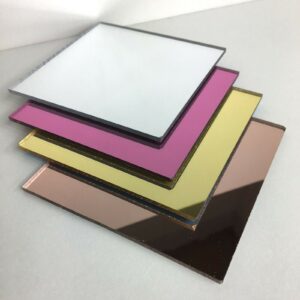

However, there are several types of acrylic sheets for users to choose from, all of which differ in price, such as transparent acrylic sheets, lucite block, coloured acrylic sheets, and mirrored sheeting.

2. Minimal reflection: Plexiglass is a better option than glass for windows because it produces less glare and reflection. Unlike glass which produces more reflection and becomes more discoloured as the thickness increases, plexiglass can retain its clarity to allow adequate light transmission no matter how thick the window is.

3. Superior strength: Plexiglass is preferred to glass for windows because of its sturdiness. Plexiglass is estimated to be 17 times stronger and sturdier than glass. Unlike glass which can be easily damaged by high impact, plexiglass poses more difficulty to both intentional and accidental damage.

Another perk of using plexiglass for windows is that there is a lesser chance of injuries to people in the environment if the window sheeting breaks, unlike glass windows which could cause severe injuries.

4. Easy to use: Another major advantage of using plexiglass for windows instead of glass is that it is easier to use than glass. Plexiglass is easier to cut and can be carved into different shapes for creative window designs, unlike glass, which poses many difficulties to cut and shape.

Common Uses of Plexiglass

Some common uses of plexiglass include:

1. Commercial and residential windows: Plexiglass is used as a substitute for glass windows in many commercial and residential buildings. Home and business owners are more inclined to use plexiglass for windows instead of glass to guarantee safety and durability while saving money.

2. Skylights: Unlike glass, with its limitations in terms of shaping or installing roofs, plexiglass is versatile and can be used for different types of roofs. Also, plexiglass is more resilient to adverse and prolonged exposure to the elements, making it a better option for skylights in homes or businesses.

3. Solar panels: Plexiglass is a good option for covering solar panels, not only for their better resilience to sunlight but also for their ability to transmit light so that the panels can be charged. Also, plexiglass is easier to cut and shape for different shapes and sizes of solar panels.

4. Secure facilities: Plexiglass is more suited for secure facilities because it is more difficult to damage than glass. Facilities like ATMs, COVID-19 protection borders, and the like can be protected with plexiglass.

5. Shower enclosures: Plexiglass is preferred for its sturdiness and durability and for how easy it is to maintain. Plexiglass is easy to clean and is cheaper and safer for your bathroom than glass, as it is more difficult to clean and maintain and is also prone to damage.

6. Gardens and greenhouses: Plexiglass is a great option for indoor gardens and greenhouses as it is better suited to withstand the effects of the elements as well as being easier to clean and maintain. It also provides more security for the gardens than glass that can easily be shattered.

Ready to embrace the benefits of plexiglass? Canada Plastics & Belting Inc. is one of the top plexiglass suppliers in the GTA. We can also custom-cut the sheets to your specific dimensions. Contact us today or call us at (416) 291-3036 for a free quote.

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

Acrylic (commonly called

Acrylic (commonly called

Corrugated plastic is a fluted plastic that is lightweight but rigid. With its big rectangular flutes running the entire length of it, the corrugated plastic is extruded and has a very long outdoor lifespan.

Corrugated plastic is a fluted plastic that is lightweight but rigid. With its big rectangular flutes running the entire length of it, the corrugated plastic is extruded and has a very long outdoor lifespan.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

A greenhouse is a glass structure where you cultivate plants that require protection against the weather. Growing seasons can be prolonged and even improved with greenhouses since they act as a barrier between the environment and what you are growing. They offer protection from pests and extreme cold or heat.

When it comes to walk-in freezers, cold storage, and other commercial food and restaurant areas,

When it comes to walk-in freezers, cold storage, and other commercial food and restaurant areas,

There are many different types of

There are many different types of

ABS is a powerful engineering thermoplastic that is typically used in 3D printing. ABS is made up of three different monomers: acrylonitrile, butadiene, and styrene. ABS gets its impact resistance from the acrylonitrile, its heat stability from the butadiene, and its rigidity from the styrene.

ABS is a powerful engineering thermoplastic that is typically used in 3D printing. ABS is made up of three different monomers: acrylonitrile, butadiene, and styrene. ABS gets its impact resistance from the acrylonitrile, its heat stability from the butadiene, and its rigidity from the styrene.