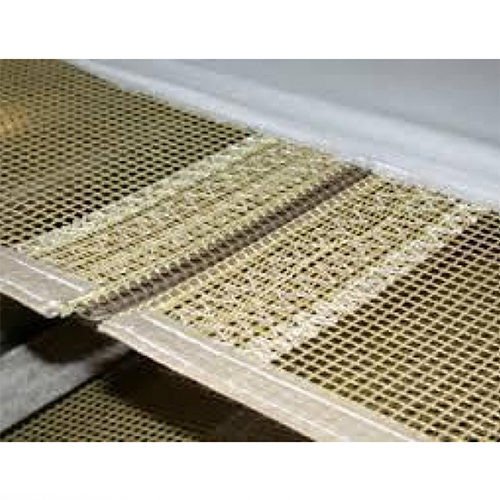

The essence of a manufacturing plant lies in its machinery, with conveyors playing a pivotal role in transporting materials between stages. Polytetrafluoroethylene (PTFE), known for its non-stick and heat-resistant properties, forms the foundation of PTFE mesh conveyor belts. The mesh structure is essential in industries requiring uniform heat transfer, such as food processing and printing.

The essence of a manufacturing plant lies in its machinery, with conveyors playing a pivotal role in transporting materials between stages. Polytetrafluoroethylene (PTFE), known for its non-stick and heat-resistant properties, forms the foundation of PTFE mesh conveyor belts. The mesh structure is essential in industries requiring uniform heat transfer, such as food processing and printing.

Engineered for versatility, these belts can withstand extreme temperatures, chemical reactions, and high-speed operations, maintaining performance across various industrial uses. In this blog post, we’ll explore the features and industrial applications of PTFE mesh conveyor belts and offer insights into optimizing industrial performance with them.

High-Speed Operations

In facilities where throughput speed is central, conveyor belts are the linchpins that keep the entire operation moving. They can drastically boost output and efficiency:

- Optimizing Material Handling Processes: The use of a PTFE mesh conveyor belt for material movement streamlines operations by reducing bottlenecks and enhancing efficiency through precisely calibrated belt speeds.

- Minimizing Downtime and Production Delays: PTFE mesh conveyor belts are highly reliable and sturdy, reducing the risk of failures and enhancing operational uptime for improved productivity.

Consistent Performance

Conveyor belts, when designed with precision, offer extraordinary reliability and can maintain:

- Uniform Heat Distribution: In industrial ovens and drying units, the uniform heat transfer capacity of PTFE mesh belts results in consistent product quality and reduced processing times.

- Smooth Material Flow: The surface of PTFE mesh conveyor belts minimizes friction and provides a consistent platform for materials, enhancing overall smoothness and accuracy in the production process.

Durability and Wear Resistance

Industrial production is often a test of endurance. Conveyor belts are no exception and must withstand arduous conditions:

- Withstanding Heavy Loads: PTFE mesh conveyor belts are engineered to handle substantial amounts of material without strain, making them a reliable choice for heavy-duty tasks.

- Resisting Abrasion and Impact: The mesh construction of these belts distributes impact forces, reducing wear and tear over time.

Low Maintenance Requirements

The features of PTFE mesh conveyor belts result in:

- Reduced Need for Repairs and Replacements: With their high resistance to wear and tear, PTFE mesh belts offer lower maintenance costs and enhanced cost-efficiency.

- Longevity in Harsh Operating Conditions: The durability of these belts translates to a longer lifespan even in the harshest industrial environments, outlasting traditional alternatives.

Non-Stick Surface Properties

One of the most valuable traits of PTFE mesh conveyor belts is their non-stick nature, which allows for:

- Prevention of Material Buildup: Materials in various states, from liquid to solid, are less likely to adhere to the belt, preventing jams and interruptions.

- Facilitation of Easy Cleaning: The non-stick quality also means that the belts can be cleaned quickly and effectively, maintaining the highest standards of hygiene in food and pharmaceutical manufacturing.

Customization Options

PTFE mesh conveyor belts can:

- Be Tailored for Specific Applications: With the ability to customize mesh size, belt thickness, and even edge reinforcement, these belts can be optimized for the unique demands of each manufacturing process.

- Integrate Advanced Technologies: Manufacturers are increasingly incorporating radio frequency identification (RFID) tags and sensors within PTFE mesh belts, allowing for advanced tracking and automation capabilities.

Contact Canada Plastics and Belting Inc. to Optimize Your Industrial Processes with PTFE Mesh Conveyor Belts

From enhancing material handling and reducing maintenance to ensuring durability and boosting cleanability, PTFE mesh conveyor belts are veritable assets for industries across the spectrum. By choosing these belts, industries can significantly cut down on production costs and improve operational efficiencies. Their innovative design and integration capabilities promise a future-proofed investment in the manufacturing sector.

For more information on how PTFE mesh conveyor belts can be integrated into your operations, or for customized belt solutions, contact Canada Plastics and Belting Inc. to kickstart a new era of efficiency and reliability in your industrial processes!