The roofing industry has made a lot of advancements over the past few decades. Asphalt shingles, ceramic tiles, wood, slate, and even metal are among the most commonly used materials for residential roofs. But the use of these materials has slowly started to dwindle in recent years with the introduction of corrugated plastic (PVC) roofing sheets. Plastic sheet suppliers recommend using polycarbonate roofing sheets because they have a lot of the same and even enhanced structural and aesthetic qualities of traditional roofing materials at a fraction of the cost.

The roofing industry has made a lot of advancements over the past few decades. Asphalt shingles, ceramic tiles, wood, slate, and even metal are among the most commonly used materials for residential roofs. But the use of these materials has slowly started to dwindle in recent years with the introduction of corrugated plastic (PVC) roofing sheets. Plastic sheet suppliers recommend using polycarbonate roofing sheets because they have a lot of the same and even enhanced structural and aesthetic qualities of traditional roofing materials at a fraction of the cost.

What Are Plastic Roofing Sheets?

Plastic roofing sheets are made out of polycarbonate, which is a durable thermoplastic material. Aside from their excellent chemical composition and ability to withstand high temperatures for long periods of time, plastic roofing sheets are also extremely versatile and can be used for a variety of different structures.

In fact, special pergola plastic sheets and plastic sheets for gazebos are also seen a recent surge in popularity over the past few years. For expert installation and maintenance, partnering with a trusted roofing contractor can ensure your roofing project lasts for years. Since these plastic sheets can be designed and manufactured to resemble other materials such as glass or even wood, they have a plethora of aesthetic possibilities.

What Are the Different Types of Plastic Roofing Sheets?

There are four different types of plastic roofing sheets, each of which has unique aesthetic and functional properties that make them a good fit for various structural applications.

Corrugated Plastic Roofing Sheets

Corrugated plastic roofing sheets are primarily used for structures that are strictly meant to act as a form of cover, protection, or storage facility. They are used for agricultural structures such as farmhouses, outdoor sheds, detached carports or garages, and other types of residential storage units. The ridges in the sheets provide additional structural durability that’s resistant to external damages and protects the interior of the structure.

Flat Polycarbonate Roofing Sheets

Industrial complexes and commercial buildings typically consist of flat polycarbonate roofing panels. Polycarbonate sheets are incredibly durable and can withstand frequent exposure to high and low temperatures. They’re also very low maintenance, which makes them the ideal choice for warehouses, manufacturing facilities, and multi-store retail complexes.

PVC Sheets

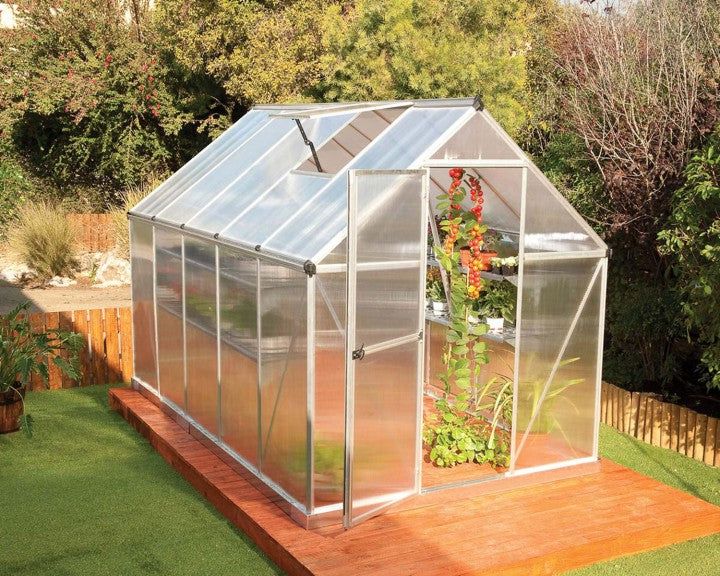

PVC, which stands for polyvinyl chloride, is an excellent roofing choice for greenhouses and other structures that require high sunlight transmittance. It’s incredibly lightweight, easy to install, and low maintenance.

Acrylic Plastic Roofing Sheets

Like its predecessors, acrylic roofing sheets also provide optimal natural light transmittance and low maintenance. They’re also far more affordable than traditional roofing materials. The main difference is that acrylic sheets are heat bent so they can be customized to fit a variety of structural angles. What sets acrylic roofing sheets over the top is that they’re made from recycled plastic materials, which makes them the most eco-friendly and sustainable option.

Why Should You Invest in Plastic Roofing Sheets?

There are a lot of great advantages of using plastic roofing sheets in lieu of traditional materials that will either eventually break down and need to be replaced, end up in landfills, or are too costly to maintain.

Plastic roofing sheets come in a variety of configurations, colour options, and can be customized to virtually any roofing structural dimensions a lot more easily than asphalt, ceramic tiles, and other materials. Here are just some of the top reasons why residential and industrial roofing contractors should make the switch to plastic panels.

Plastic Sheets Are Cost-Effective

Plastic sheets are far more affordable than other roofing materials. Moreover, they’re easier and faster to install, which also saves you time and money on manual labor. Since they’re low maintenance, easy to clean, and can withstand a variety of environmental conditions, they don’t need to be replaced as frequently as asphalt shingles or ceramic tiles.

Unlike metal roofs, they don’t overheat on extremely hot days and freeze when the temperatures outside dip below zero. Plastic roofs are highly energy-efficient, which saves you a lot of money in the long run on your utility bills.

Durable and Easy to Install

Most plastic sheet distributors offer extensive long-term warranties on their products because they’re confident that customers won’t actually have to use it. That’s how incredibly durable plastic roofing sheets are. They’re also incredibly lightweight and easy to install. Since they come in large sheets instead of smaller pieces, plastic roofing materials cover a larger surface area than traditional roofing materials.

This also makes the installation process a lot faster and smoother. Large sheets can easily be cut down to the necessary size on the spot without having to use special machinery or being transported back to the manufacturing facility.

Exceptional Protective Properties

Plastic roofing sheets offer excellent protection for property interiors against external elements such as harmful UV rays, wind, rain, snow, and more. They also act as extra insulation to maintain optimal temperature control inside your property.

Stabilization Against UV Light

Another advantage of plastic roofing sheets is that they offer exceptional UV protection without reducing even light distribution and transmittance throughout your property. You can enjoy all the natural lighting you want in your home or business without putting yourself and others at risk of high UV exposure.

Fire-Resistant

Thermoplastic roofing materials have a Class-A fire resistance rating, which is the highest rating any material can get. That means that your roof can protect you and your property and even stop the fire from spreading and destroying the entire structure.

Weather and Water Resistant

Plastic roofing materials are weather and water-resistant. This means they can withstand water retention and therefore aren’t susceptible to the development of mold, fungus, mildew, leaks, and other types of water-related structural damages.

Prevents Pests from Getting in

Since thermoplastics are able to withstand extreme inclement weather conditions and won’t sustain damages as easily as other roofing materials, this prevents pests such as rodents, insects, and animals from getting into your home through the roof.

Canada Plastics & Belting Inc. is one of the leading plastic sheet suppliers in Toronto and the GTA. We offer a wide range of plastic roofing options, thicknesses, colours, and so much more. Contact us today to learn more about our products or visit our showroom in Scarborough!

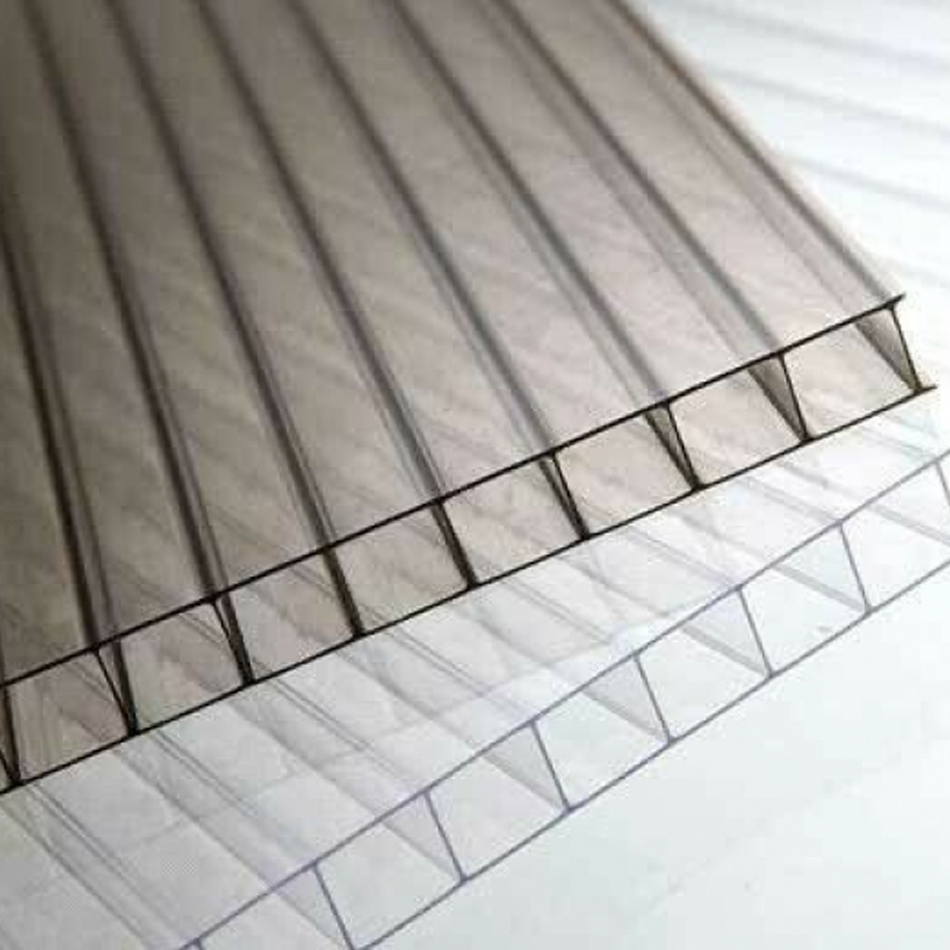

Over the past few years, polycarbonate twin wall sheet suppliers in Canada have been very busy fulfilling large orders for their signature products. These thermoplastic building materials are the perfect replacement for glass. They’re made to mimic the appearance and certain characteristics of glass, but they have a lot more advantages. They can be used for a number of different construction projects. In fact,

Over the past few years, polycarbonate twin wall sheet suppliers in Canada have been very busy fulfilling large orders for their signature products. These thermoplastic building materials are the perfect replacement for glass. They’re made to mimic the appearance and certain characteristics of glass, but they have a lot more advantages. They can be used for a number of different construction projects. In fact,

Polycarbonate Corrugated Panels is one of the most versatile and commonly used building materials currently on the market. Horticulturists, in particular, have made excellent use of multiwall sheets for greenhouses thanks in large part to their numerous qualities.

Polycarbonate Corrugated Panels is one of the most versatile and commonly used building materials currently on the market. Horticulturists, in particular, have made excellent use of multiwall sheets for greenhouses thanks in large part to their numerous qualities.

Polycarbonate roofing panels have been around in the construction industry for decades, but have only recently started gaining popularity for various design and building applications such as greenhouse structures. The reason for its slow ascent into mainstream uses for gazebo roofing is because most people like to stick to old faithful: glass. What they don’t realize is that there are a lot of great benefits to using greenhouse polycarbonate sheets instead. Unfortunately, there’s a lot of misinformation going around about the efficacy of greenhouse polycarbonate sheets and how they work. To help clear the air, here are some of the biggest myths and misconceptions that you should know about so you can make a more informed decision.

Polycarbonate roofing panels have been around in the construction industry for decades, but have only recently started gaining popularity for various design and building applications such as greenhouse structures. The reason for its slow ascent into mainstream uses for gazebo roofing is because most people like to stick to old faithful: glass. What they don’t realize is that there are a lot of great benefits to using greenhouse polycarbonate sheets instead. Unfortunately, there’s a lot of misinformation going around about the efficacy of greenhouse polycarbonate sheets and how they work. To help clear the air, here are some of the biggest myths and misconceptions that you should know about so you can make a more informed decision.

Roofing is one of the most important components when it comes to commercial and residential property construction. These days, there’s no shortage of roofing system material options to choose from. Among the many options are wood, clay, stone, metal, and polycarbonate plastic.

Roofing is one of the most important components when it comes to commercial and residential property construction. These days, there’s no shortage of roofing system material options to choose from. Among the many options are wood, clay, stone, metal, and polycarbonate plastic.

Multiwall polycarbonate sheets are quickly becoming the go-to material for a lot of indoor, outdoor, commercial, and industrial construction projects and applications. In addition to being extremely lightweight and durable,

Multiwall polycarbonate sheets are quickly becoming the go-to material for a lot of indoor, outdoor, commercial, and industrial construction projects and applications. In addition to being extremely lightweight and durable,