Polycarbonate roofing sheets have become increasingly popular in recent years due to their durability, lightweight design, and ability to provide natural light. These highly versatile sheets are commonly used in commercial and residential buildings for roofing, skylights, and walls. However, proper planning and consideration must be taken into account before installation to ensure success.

Polycarbonate roofing sheets have become increasingly popular in recent years due to their durability, lightweight design, and ability to provide natural light. These highly versatile sheets are commonly used in commercial and residential buildings for roofing, skylights, and walls. However, proper planning and consideration must be taken into account before installation to ensure success.

Factors such as climate, wind loads, and building codes must be carefully evaluated to determine the appropriate thickness and size of the sheets. Furthermore, the installation process itself requires attention to detail to ensure proper sealing and waterproofing. With proper planning, polycarbonate roofing sheets can provide not only aesthetic value but also long-lasting durability to any structure.

Read on for more details on what to consider when installing polycarbonate sheets for roofing.

How to Select the Right Polycarbonate Sheets

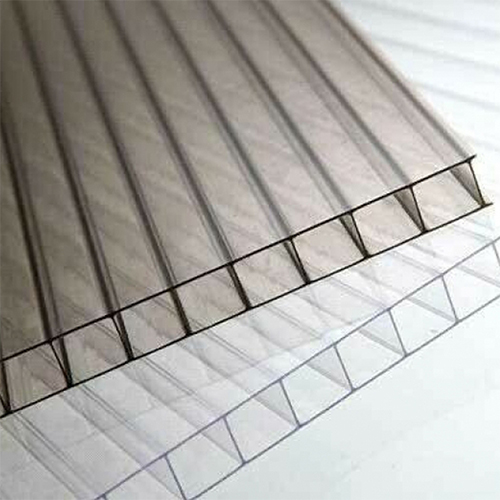

Selecting the right polycarbonate sheets for your roof requires careful consideration. One important factor is thickness. The thickness of the sheets affects their ability to resist impact and withstand weather conditions. Length is also important, as it determines how many sheets are needed for your project and affects the overall cost. Weight is another consideration, as heavier sheets can be more difficult to install and may require additional support.

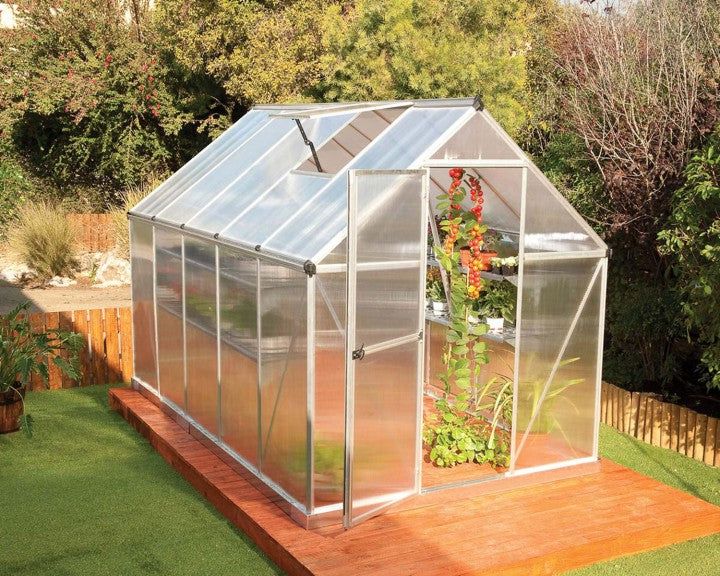

Additionally, the location and intended use of the roof must be considered. Do you intend to use the sheets for a greenhouse or just to create a covered patio? Roofs in areas prone to hailstorms or heavy rain may require thicker sheets. In contrast, roofs in sunny locations may benefit from lighter sheets that allow more natural light to enter.

Being mindful of these factors will ultimately ensure optimal performance and longevity.

Pre-Installation Considerations

To ensure proper installation and minimize potential issues, follow these guidelines when working with your polycarbonate sheets:

- For curved roofing, select a sheet thickness that matches the necessary bending radius.

- When cutting the sheets, ensure that they are securely fixed to prevent vibration and do not remove the protective film.

- Do not place sheets directly on coarse surfaces or lean them against walls.

- Clean frames thoroughly and ensure that the insert groove surface is flat.

- Allow enough space for expansion and contraction when inserting the sheets.

- Use a silicone sealant for filling any gaps.

- Make sure the protective film faces the sun, and remove only when the installation is finished.

Tools and Materials Needed for Installing Polycarbonate Roofing Sheets

For a successful installation, you will need a few essential tools including:

- A drill

- A jigsaw or circular saw

- A tape measure

- Silicone sealant

- Screws

- Washers

In terms of materials, you will need:

- Polycarbonate roofing sheets

- Glazing bars (aluminum profiles)

- End caps

Polycarbonate Roofing Sheet Installation Process

Here’s a handy guide to help you through the installation process.

First, gather all necessary tools and materials we listed above. Then, measure and cut the sheets to size, leaving a 50 mm overhang at the eaves and ridge.

Drill holes into the sheets and attach the screws with caps, using at least six screws per sheet. Apply a silicone sealant to the gaps between the sheets and secure the ridge cap over the overlapping sheets.

Finally, fit the polycarbonate end closures to the bottom of the sheets, creating a neat finish.

Safety Considerations When Installing Polycarbonate Roofing Sheets

Installing polycarbonate roofing sheets can be challenging, but with the right safety precautions, it becomes an effortless task. First and foremost, it is essential to wear the right personal protective equipment (PPE). Wear gloves, safety boots, and protective eyewear to prevent injuries and reduce the risk of accidents.

Also follow safe work practices, such as using proper equipment, placing ladders on level ground, and using scaffolding or safety harnesses when working at heights. Lastly, ensure that the surfaces around the area are free from clutter and secured to avoid tripping hazards.

Get Your Polycarbonate Sheets from Canada Plastics and Belting Inc.

When using polycarbonate, it’s important to take into consideration the pros and cons involved as well as proper planning and installation for the long-term performance of this material. The intended location and use of the structure and the appropriate thickness, length, and weight of the sheets should be considered when installing polycarbonate as part of a roofing system.

At Canada Plastics and Belting Inc., we have the expertise to provide you with quality product and value-based solutions so that your roofing job is done right in less time. Contact us to find out more about our selection of polycarbonate products and get started on putting together the ideal roofing system today!