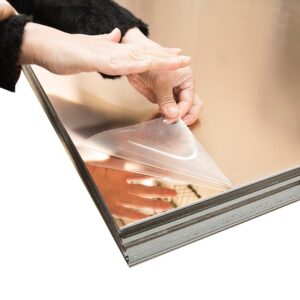

An acrylic mirror sheet is a piece of plastic that has been treated to have the same reflective properties as a traditional glass mirror. The surface of the sheet consists of thousands of tiny, mirrored facets, which give it its highly reflective appearance.

An acrylic mirror sheet is a piece of plastic that has been treated to have the same reflective properties as a traditional glass mirror. The surface of the sheet consists of thousands of tiny, mirrored facets, which give it its highly reflective appearance.

Acrylic mirror sheets are typically thinner and lighter than glass mirrors, making them easier to work with and install. Additionally, many people prefer acrylic mirrors for their more modern appearance.

Below we list some helpful tips on how to use, cut, and clean acrylic mirror sheets for your various applications.

How to Use Acrylic Sheets

When working with an acrylic mirror sheet, it is important to take the necessary precautions to ensure a safe and effective installation.

- Always wear appropriate safety equipment, such as gloves, safety glasses, and protective clothing, when handling an acrylic mirror sheet.

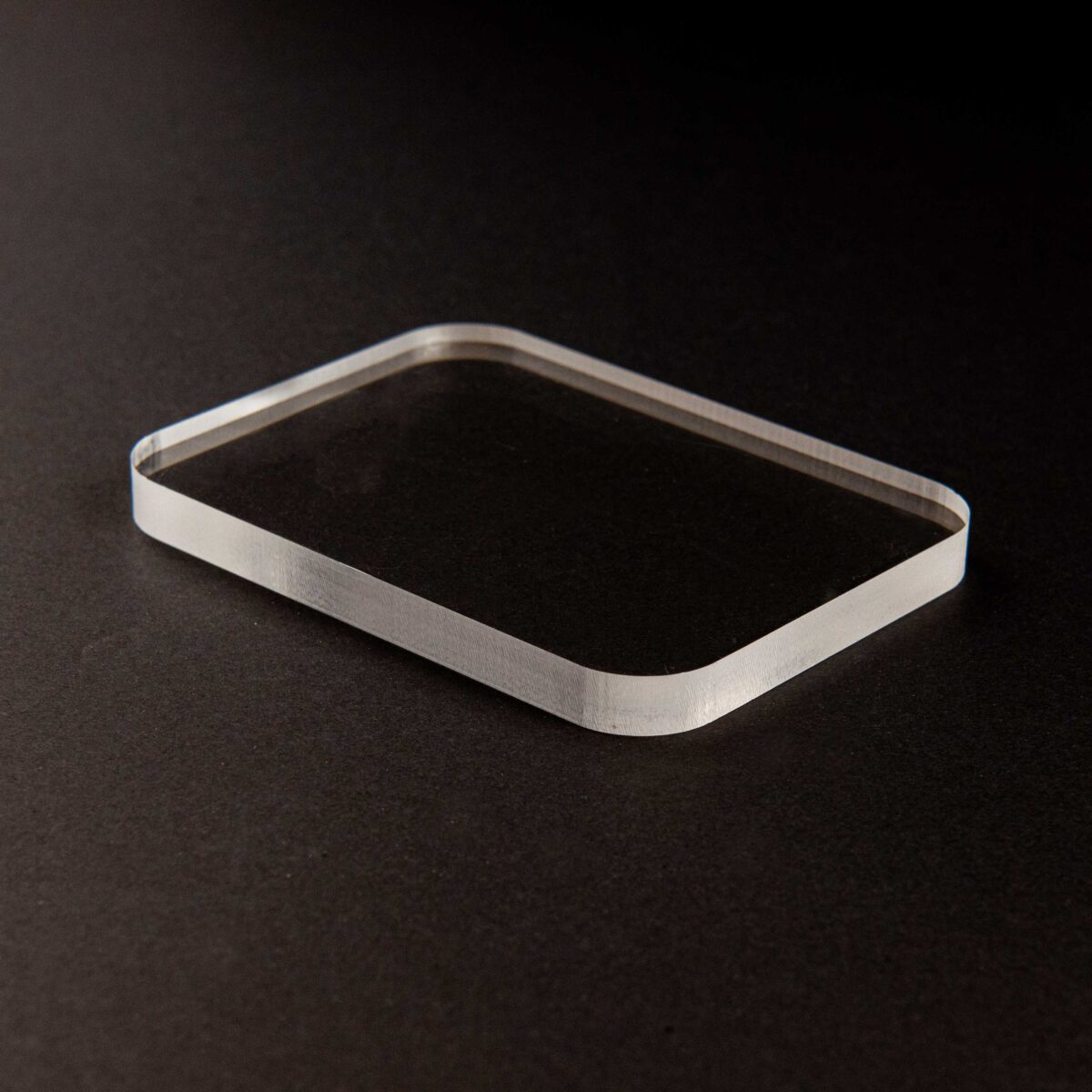

- Choose an acrylic mirror sheet that is the right size and shape for your application. Acrylic mirror sheets are available in a wide range of sizes, shapes, and thicknesses, so be sure to choose one that will work well with your intended use.

- Acrylic mirror sheets can be glued, screwed, or bolted into place. Be sure to use the appropriate adhesive, screw, or bolt for your particular application.

- Acrylic mirror sheets can be used for various purposes, such as for interior design and home décor, in commercial and retail settings, as safety mirrors for children and other basic wall-mounted unbreakable mirrors, as well as outdoors for signage.

- Acrylic mirrors do not distort images as much as traditional glass mirrors, but they can still produce some distortions. For this reason, it’s important to choose an acrylic mirror sheet that has been optical quality tested to ensure it meets your requirements.

- Always store acrylic mirror sheets in a cool, dry place when not in use. Exposure to high temperatures or moisture can cause the material to warp or become brittle over time, which can affect its performance and appearance.

How to Cut Acrylic Mirrors Sheets

Acrylic mirror sheets can be cut with a variety of common hand and power tools, including saws, routers, and grinders. However, due to the brittle nature of the material, it’s important to exercise caution. When cutting an acrylic mirror sheet, always take extra care to avoid sharp edges or rough surfaces.

Always wear protective gear, and make sure to use high-quality blades when cutting. Use a sharp, clean blade to avoid chipping or cracking the mirror surface.

How to Clean Acrylic Mirror Sheets

Acrylic mirror sheets can be easily damaged by harsh chemicals or cleaners, so be sure to use appropriate cleaning products and take care when wiping away dirt or dust. Acrylic mirror sheets can be cleaned with a soft, dry cloth. If necessary, you can use a mild soap or detergent to remove stubborn dirt or grime.

When cleaning an acrylic mirror sheet, always take care to avoid sharp edges or rough surfaces. Use a soft, clean cloth to avoid scratching the mirror surface.

Contact a High-End Acrylic Mirror Sheet Distributor in Toronto

Whether you need a high-performance mirror for an outdoor application or a decorative mirror for your home, acrylic mirror sheets are an excellent choice. With so many advantages, it’s no wonder that acrylic mirror sheet is one of the most popular choices for mirrors today.

As one of the leading acrylic sheet distributors in Toronto, Canada Plastics & Belting, Inc. has a wide range of products available in an assortment of colors and textures that can be custom-tailored to your project specifications. Contact us today to learn more.

Related Product:

Made of polymethyl methacrylate (PMMA), also known as acrylic, acrylic mirror sheets have many uses in a wide range of industries. This type of plastic is highly durable and offers excellent resistance to weathering, moisture, heat, and UV radiation. In addition, acrylic mirror sheets are lightweight and easy to work with, making them ideal for a variety of applications.

Made of polymethyl methacrylate (PMMA), also known as acrylic, acrylic mirror sheets have many uses in a wide range of industries. This type of plastic is highly durable and offers excellent resistance to weathering, moisture, heat, and UV radiation. In addition, acrylic mirror sheets are lightweight and easy to work with, making them ideal for a variety of applications.

Despite boasting a durable and scratch-resistant surface,

Despite boasting a durable and scratch-resistant surface,

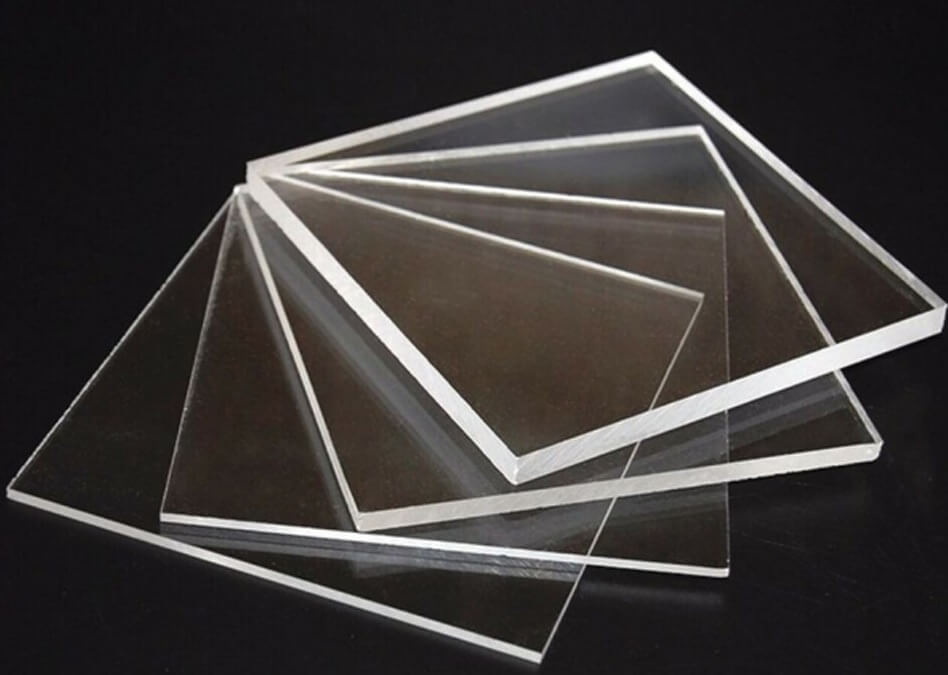

Considering it’s one of the most versatile and durable materials in the world, there are countless uses of acrylic sheets. Acrylic sheet suppliers and distributors provide their materials to various industrial and commercial businesses that manufacture many different types of structures and products.

Considering it’s one of the most versatile and durable materials in the world, there are countless uses of acrylic sheets. Acrylic sheet suppliers and distributors provide their materials to various industrial and commercial businesses that manufacture many different types of structures and products.

Acrylic is one of the most versatile building materials in the world. It can be used for a wide range of applications across numerous industries, but its main purpose is to act as a more affordable and durable replacement for glass. Hence, acrylic has many of the same properties of glass including appearance and transparency options. The main exception is that acrylic is virtually unbreakable, can last a very long time, and is easier to maintain.

Acrylic is one of the most versatile building materials in the world. It can be used for a wide range of applications across numerous industries, but its main purpose is to act as a more affordable and durable replacement for glass. Hence, acrylic has many of the same properties of glass including appearance and transparency options. The main exception is that acrylic is virtually unbreakable, can last a very long time, and is easier to maintain.

Acrylic sheets are a cost-effective and lightweight alternative to glass in the construction industry. While acrylic plastic sheets are commonly used in commercial construction, they’re quickly becoming a more popular choice for residential new builds as well. Not only is acrylic cheaper and easier to produce than glass, but it’s also easier and lighter to transport from the manufacturing plant to the jobsite. Plus, acrylic plastic sheets are also 17 times more durable than glass and offer enough flexibility to be moulded and shaped to fit into any structural design and size.

Acrylic sheets are a cost-effective and lightweight alternative to glass in the construction industry. While acrylic plastic sheets are commonly used in commercial construction, they’re quickly becoming a more popular choice for residential new builds as well. Not only is acrylic cheaper and easier to produce than glass, but it’s also easier and lighter to transport from the manufacturing plant to the jobsite. Plus, acrylic plastic sheets are also 17 times more durable than glass and offer enough flexibility to be moulded and shaped to fit into any structural design and size.