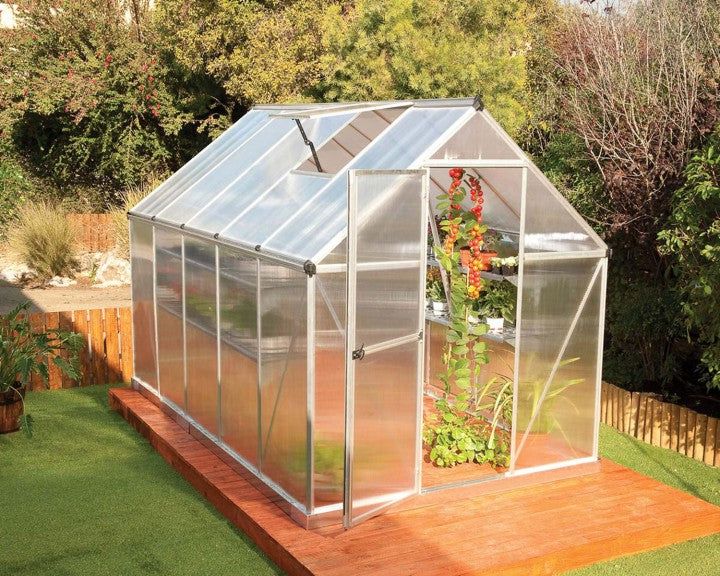

So you’ve decided to build a greenhouse to enjoy year-round fresh produce or exotic plants and flowers. Have you thought about the materials you will use to construct it? One of the most important components of a greenhouse is its covering, particularly if you live in an extreme, harsh climate. Choosing the right greenhouse sheet is important for shielding your plants from elements as well as providing them with the sunlight necessary to grow.

In this blog post, we’ll cover the ins and outs of greenhouse sheets to help you select the best covering for your needs.

Understanding the Types of Greenhouse Sheet Materials

There are four main types of greenhouse sheets:

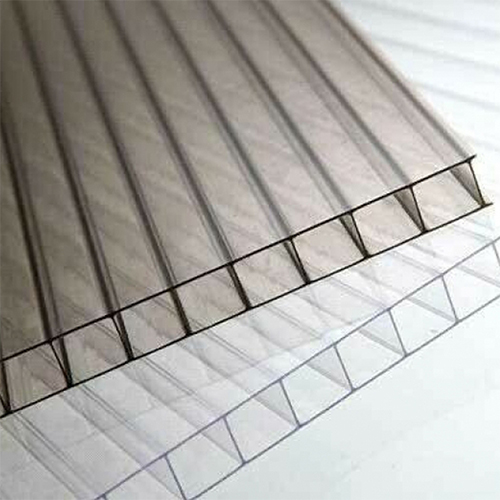

- Polycarbonate: Far stronger than glass and nearly as transparent, polycarbonate plastic is a popular choice for greenhouse coverings. A virtually unbreakable polycarbonate greenhouse sheet is shatter-proof and ultraviolet (UV) ray-resistant while also being lightweight.

- Polyethylene: Polyethylene is the most commonly used greenhouse material due to its low cost and ease to maintain. It also has excellent light transmission, which means it allows plenty of light in for your plants.

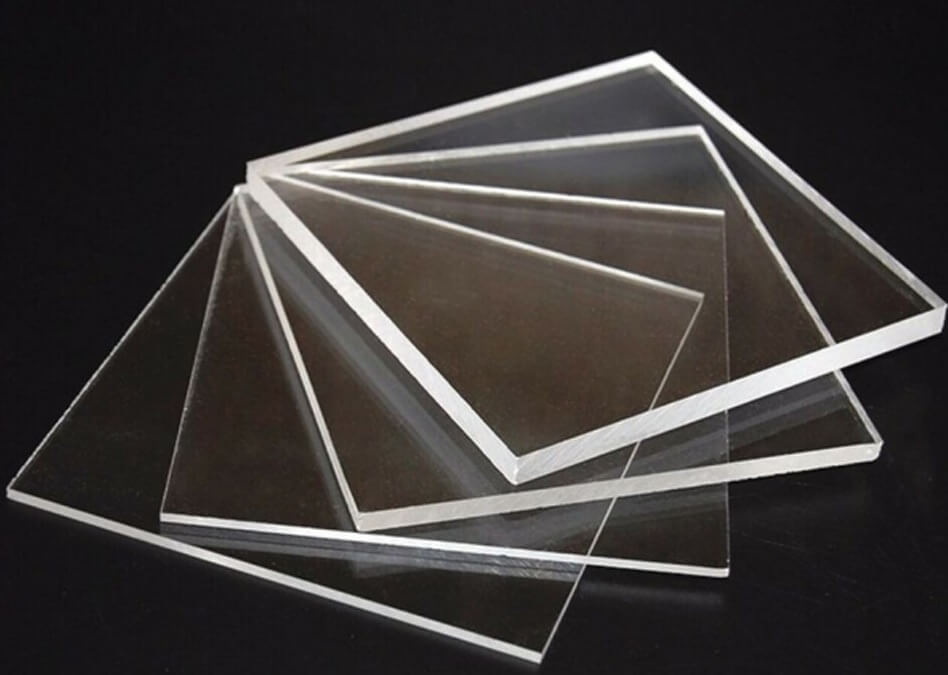

- Acrylic: Like polycarbonate, acrylic is much stronger than glass while weighing half as much. It’s additionally more transparent than glass, allowing more than 90% of light to pass through. An acrylic greenhouse sheet will also cost you less than a comparable polycarbonate sheet.

- Glass: Glass has traditionally been used for greenhouse walls and ceilings. Glass sheets give your structure a classic look, and from an environmental standpoint, it is non-toxic and 100% recyclable. However, glass is heavier and more prone to breakage than plastics.

Factors to Consider When Choosing a Greenhouse Sheet

When choosing a greenhouse sheet, there are several factors to keep in mind to ensure that you are creating the ideal environment for your plants to thrive.

Climate Considerations

- Cold Climates: When choosing a greenhouse sheet for cold climates, it is important to consider the insulation value of the material. Polycarbonate sheets are a great choice for cold climates as they have excellent insulating properties, helping to keep your greenhouse warm in winter and cool in summer. Moreover, polycarbonate sheets are very durable and can withstand extreme temperatures without cracking or breaking.

- Hot and Sunny Climates: For hot and sunny climates, you’ll want to consider the amount of light that the sheet will allow in. Clear or white sheets are ideal, as they allow plenty of light into the greenhouse while still providing some shade from direct sunlight. You’ll also want a sheet with good heat-retention properties to keep the internal temperature of the greenhouse stable during hot summer days. Also make sure that any ventilation openings are covered with insect screens to prevent pests from entering the greenhouse.

- Variable Climates: If you live in an area with variable climates, you may want to consider using two different types of greenhouse sheets: one for colder months and one for warmer months. For example, during colder months, you could use polycarbonate sheets for their insulating properties, and during warmer months, you could use acrylic panels that allow more light into the greenhouse but offer less insulation than polycarbonate sheets do.

Crop-Specific Needs

- High-Light Plants: All plants require a certain amount of sunlight for photosynthesis or energy production. But high-light plants need at least six hours of direct sunlight per day to thrive. So, if you’re growing sun-soaking plants such as tomatoes or peppers, then you’ll need a sheet that transmits lots of light. Polycarbonate and acrylic sheets work well for this purpose.

- Shade-Loving Plants: Shade-loving plants like ferns and orchids may burn in direct sunlight. Therefore, they require a material with lower levels of light transmission, such as polycarbonate. Many greenhouse growers also use cloth shades to protect shady plants during the spring and summer months.

- Temperature-Sensitive Crops: Certain crops may require specific temperatures in order to grow properly, so it’s important to choose a sheet that will help maintain the desired temperature range for your particular crop. Temperature-sensitive crops such as strawberries or melons require a sheet that helps keep the temperature within an optimal range for those crops.

Durability and Longevity

- Resilience against Environmental Stressors: Durability is another important factor to consider when choosing a greenhouse sheet. Greenhouse sheets need to be able to withstand harsh weather conditions such as strong winds, hail, and heavy rain without becoming damaged or torn.

- Resistance to UV Radiation and Weathering: Over time, all plastics degrade with exposure to UV rays. Polycarbonate and acrylic varieties are generally your best options for UV resistance, but many greenhouse-grade polyethylene sheets contain UV stabilizers that limit degradation.

- Expected Lifespan of Different Materials: Polycarbonate and acrylic sheets are considered the most durable materials used in greenhouses and can last from 10 to 20 years with proper care and maintenance. Polyethylene is not as durable, with a one- to five-year life expectancy, but can still provide adequate protection from the elements if cared for properly. Glass has an indefinite lifespan, provided it doesn’t encounter any golf balls, rocks, or hailstorms.

Light Transmission Requirements

- Light Diffusion Needs: Light diffusion is a hot topic in the greenhouse community. Diffused light scatters sunlight across the greenhouse, distributing it evenly for your plants and allowing deeper penetration for optimized photosynthesis. Acrylic, polycarbonate, and polyethylene sheets can be treated with additives to better diffuse light.

- Balancing Natural Light with UV Protection: It is vital to strike the right balance between natural light and UV protection to minimize the risk of plant damage. While natural light is essential for photosynthesis, too much UV exposure can lead to leaf burns, stunted growth, and even death. This balance can be achieved through the use of greenhouse sheets made of high-quality materials that are UV-resistant and designed to regulate light transmission.

The Importance of Choosing the Right Material for Your Greenhouse

Choosing the right greenhouse sheet is essential for ensuring the success of your plants. When considering your options, it’s important to do your research and make informed decisions. A trusted greenhouse sheet distributor can further advise you on which materials best meet your specific needs and budget.

Contact Canada Plastics & Belting for Your Greenhouse Sheet Needs

If you’re on the hunt for a greenhouse sheet supplier in Toronto, look no further than Canada Plastics & Belting Inc. We offer a wide variety of polycarbonate, acrylic, and polyethylene sheets to suit your greenhouse needs.

Contact us today to learn more about our products.

Plexiglass is a plastic material made from polymers of methyl methacrylate (PMMA). It is one of the most sought-after plastic materials, and the reason is simple: it is a better alternative to glass because of its flexibility, UV resistance, lightweight, transparency, high impact, and chemical resistance.

Plexiglass is a plastic material made from polymers of methyl methacrylate (PMMA). It is one of the most sought-after plastic materials, and the reason is simple: it is a better alternative to glass because of its flexibility, UV resistance, lightweight, transparency, high impact, and chemical resistance.