Swimming pools are one of the most sought-after additions to homes. However, as enjoyable as they may be, they also require maintenance and protection from external elements such as debris and harsh weather conditions. That’s where polycarbonate sheets come into play. These durable materials have become increasingly popular among homeowners for several reasons.

Swimming pools are one of the most sought-after additions to homes. However, as enjoyable as they may be, they also require maintenance and protection from external elements such as debris and harsh weather conditions. That’s where polycarbonate sheets come into play. These durable materials have become increasingly popular among homeowners for several reasons.

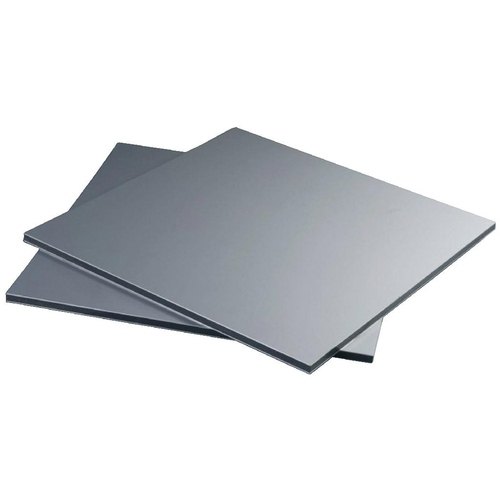

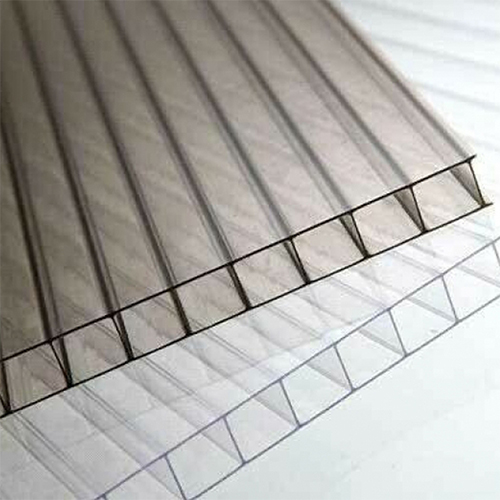

Made from a thermoplastic polymer, polycarbonate boasts a high level of impact resistance and durability, making it an excellent choice for outdoor structures like pool enclosures. In this blog post, we’ll dive into why using polycarbonate sheets for pool enclosures is not only practical but also adds a level of style to your outdoor space while providing essential protection for your beloved pool.

Benefits of Using Polycarbonate Roofing Sheet for Pool Enclosure

So, why should homeowners choose a polycarbonate pool enclosure? Let’s count the benefits.

Longer Lifespan of the Enclosure

Polycarbonate roofing sheets are made from a strong and resilient material that can withstand harsh weather conditions, such as strong winds and heavy rain. This means that your pool enclosure will last for many years without needing frequent repairs or replacements.

Easy to Customize

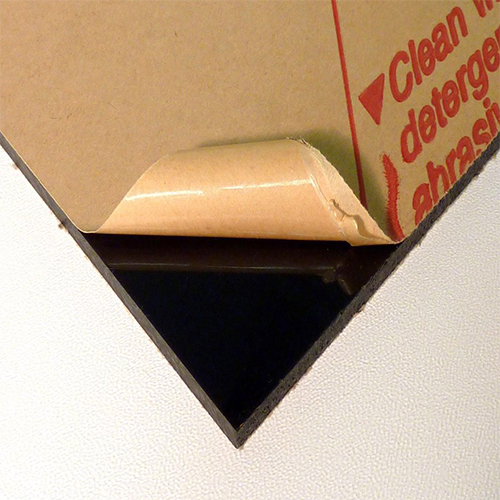

These sheets come in a variety of sizes, shapes, and colours, allowing you to create a unique and personalized enclosure for your pool. You can also choose from different levels of transparency, giving you control over how much natural light enters the space.

Better Insulation

Polycarbonate roofing sheets have excellent insulation properties, helping to regulate the temperature inside your pool enclosure. So, during hot summer days, your enclosure will stay cool and comfortable, while in colder months it will retain heat and keep the space warm.

Maintain Privacy

If privacy is a concern for you when it comes to your pool area, polycarbonate roofing sheets can provide a solution. They’re available in opaque or tinted options that can block the view from outside while still allowing natural light to enter the space, allowing you to enjoy your pool without worrying about prying eyes from neighbours or passersby.

Filter UV Rays

Polycarbonate sheets also filter out harmful UV rays. This is especially important for a pool enclosure as it not only protects you and your family from sunburn but also prevents damage to your skin and eyes.

Maintain the Water Temperature

Polycarbonate roofing sheets can help to maintain the water temperature in your pool by acting as a barrier, preventing cool air from entering the enclosure and keeping warm air trapped inside. As a result, your pool water will stay at a comfortable temperature for swimming.

Weatherproof Sheets

Polycarbonate sheets are highly weatherproof; they can withstand heavy rain, strong winds, and even hail without getting damaged or leaking. This means that you can use your pool all year round without worrying about unpredictable weather conditions ruining your plans.

Factors to Consider Before Installing Polycarbonate Pool Enclosure

Here are some things to think about before installing a polycarbonate roof for your pool’s enclosure.

Examine the Pool Area

Look at the size and shape of your pool, as well as any existing structures or obstacles that may impact the installation process. Consider factors such as sunlight exposure, wind patterns, and nearby trees or buildings that could affect the functionality of your enclosure.

Choose the Right Design

There are various designs and styles of polycarbonate pool enclosures to choose from, so take some time to explore your options. Think about aesthetics, functionality, and budget when selecting a design.

Know the Maintenance Required

Before installing polycarbonate pool enclosures, make sure you understand the maintenance requirements and are prepared to commit to them. This can include tasks such as cleaning the panels and lubricating moving parts.

Hire an Expert

A professional installer will have experience working with these structures and can ensure proper installation for optimal function and safety. Plus, they can offer valuable advice on design choices and maintenance tips.

Polycarbonate Roofing Sheets from Canada Plastics and Belting Inc.

Polycarbonate roofing sheets are a versatile and practical option for those looking to add a pool enclosure to their home. Canada Plastics and Belting Inc. is here to help make this decision even easier. We have a wide selection of high-quality polycarbonate sheets available at competitive prices, ensuring that every homeowner can find the perfect fit for their pool enclosure needs.

Contact us today to learn more about our inventory and how we can help you achieve the ultimate pool experience!

Are you in the market for a strong, durable roofing solution for your carport? If so, look no further than polycarbonate roofing sheets. Polycarbonate sheeting is an increasingly popular choice among homeowners because of its lightweight nature and excellent performance in extreme temperatures. With its impact-resistant surface and virtually unrivalled strength-to-weight ratio, polycarbonate roofing is undoubtedly one of the best options when it comes to carports.

Are you in the market for a strong, durable roofing solution for your carport? If so, look no further than polycarbonate roofing sheets. Polycarbonate sheeting is an increasingly popular choice among homeowners because of its lightweight nature and excellent performance in extreme temperatures. With its impact-resistant surface and virtually unrivalled strength-to-weight ratio, polycarbonate roofing is undoubtedly one of the best options when it comes to carports.