Innovation is the beacon that has guided the textile manufacturing industry through the ages. From the first mechanized looms to today’s cutting-edge automation, the goal has always been the same: to enhance efficiency without compromising on quality. In this pursuit of progress, a new key player has quietly yet profoundly changed textile production processes—the advanced polytetrafluoroethylene (PTFE) conveyor belt.

Innovation is the beacon that has guided the textile manufacturing industry through the ages. From the first mechanized looms to today’s cutting-edge automation, the goal has always been the same: to enhance efficiency without compromising on quality. In this pursuit of progress, a new key player has quietly yet profoundly changed textile production processes—the advanced polytetrafluoroethylene (PTFE) conveyor belt.

Keep reading as we discuss how PTFE belts are weaving a new narrative for textile manufacturers.

The Role of PTFE Belts in Textile Manufacturing

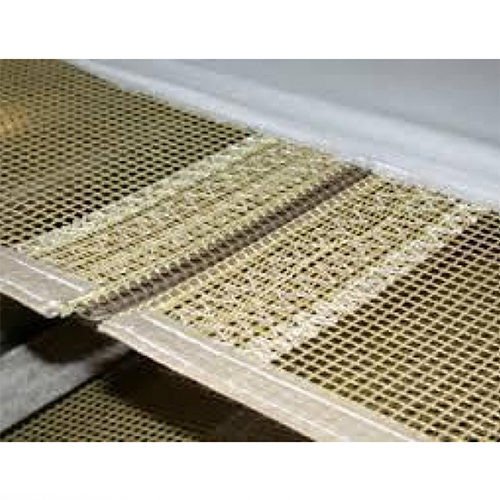

Conveyor belts are the lifeblood of the production line, responsible for transporting raw materials (e.g., fibres, yarns, and fabrics) and finished products seamlessly through various stages. They ensure the continuity of manufacturing, the precision of processes, and the fluidity of operation.

Perhaps the most complex task of a textile conveyor belt is to maintain the tension in the fabric as it moves along the production line. The conveyors need to smoothly guide the fabric, applying the perfect amount of control to ensure that the pattern, texture, and design elements remain as intended.

How New Developments in PTFE Are Benefiting the Textile Industry

Recent advancements within the PTFE universe have translated into belts with enhanced non-stick properties, unrivaled heat resistance, and steadfast resistance to a litany of chemicals—attributes that are tailor-made for the textiles domain.

Enhanced Non-Stick Properties

With improved non-stick capabilities, PTFE conveyor belts are revolutionizing the textile sector. The days of fabric snags and unexpected disruptions are on the wane. Instead, textile manufacturers are experiencing unprecedented smoothness in their operations, ensuring that every inch of fabric meets the desired standard without the imperfections that used to be common.

Improved Heat Resistance

In textile finalization processes like drying and setting, PTFE’s remarkable resistance to high temperatures is a critical attribute that ensures the conveyor belt not only survives but thrives. This translates into unyielding support for the fabric, regardless of the fiery backdrop against which it’s being shaped into a final product.

Increased Chemical Resistance

The textile world is a colour canvas, often brought to life through chemical treatments that can be harsh on machinery. PTFE belts, however, are resistant to these harsh chemicals, outlasting other conveyor materials. Their durability allows for a more sustainable production process, where machinery can withstand the chemical treatments necessary to give textiles their unique qualities.

Analysis of Productivity Gains from Using PTFE Conveyor Belts

Let’s look at some of the standout benefits of PTFE conveyor belts in terms of productivity.

Reduced Downtime

The seamless flow enabled by these belts increases the production speed and the consistent tension control contributes to the uniform quality of the produced fabrics. Overall, this translates into a significant boost to the facility’s productivity metrics.

Improved Fabric Quality

PTFE belts provide the foundation for impeccable quality, with their non-stick properties minimizing defects and ensuring that every patch of fabric that emerges reflects the manufacturer’s commitment to excellence.

Increased Production Speed and Sustainability

In the broader context, improved productivity isn’t just about numbers; it’s also about treading the path of sustainability with a lighter environmental footprint. PTFE conveyor belts lower energy consumption by facilitating faster, more efficient production processes that reduce waste and support sustainability initiatives within the textile industry.

Embrace Efficiency and Sustainability with Advanced PTFE Conveyor Belts

The infusion of PTFE conveyor belts in the textile manufacturing sector proves that even small components can spark big improvements. These belts have significantly boosted efficiency, production quality, and sustainability.

Discover what having a PTFE conveyor belt in your textile manufacturing facility can do for operations. Contact Canada Plastics and Belting Inc., the leading supplier of PTFE conveyor belts in Toronto, for a seamless transition into the world of woven excellence.

The heart of any restaurant operation is its kitchen. Here, the synergy of culinary skills and efficient design can mean the difference between churning out a memorable dining experience and a kitchen nightmare. The high-octane, quick-turnaround demand of the food industry necessitates that a restaurant’s kitchen is not only functional but adaptable to the fast pace of change as well. In this article, we’ll explore an under-the-radar secret that could revolutionize your kitchen renovations: FRP wall sheets.

The heart of any restaurant operation is its kitchen. Here, the synergy of culinary skills and efficient design can mean the difference between churning out a memorable dining experience and a kitchen nightmare. The high-octane, quick-turnaround demand of the food industry necessitates that a restaurant’s kitchen is not only functional but adaptable to the fast pace of change as well. In this article, we’ll explore an under-the-radar secret that could revolutionize your kitchen renovations: FRP wall sheets.