Did you know that the sun’s UV rays can cause irreversible damage to your furniture and belongings? As sunlight pours into your home or office, it brings with it invisible but powerful ultraviolet (UV) radiation that can wreak havoc on your valuable items. Fortunately, polycarbonate window awnings offer an effective and stylish way to protect your furniture and belongings from the harmful effects of the sun’s UV rays.

Did you know that the sun’s UV rays can cause irreversible damage to your furniture and belongings? As sunlight pours into your home or office, it brings with it invisible but powerful ultraviolet (UV) radiation that can wreak havoc on your valuable items. Fortunately, polycarbonate window awnings offer an effective and stylish way to protect your furniture and belongings from the harmful effects of the sun’s UV rays.

Understanding Sun Damage

Understanding the advantages of polycarbonate awnings can help you make an informed decision about enhancing the protection of your home’s interior.

UV radiation is a form of electromagnetic radiation emitted by the sun. While UV radiation is crucial for life on Earth, prolonged exposure to it can have adverse effects on indoor environments. When UV rays penetrate through windows, they can cause significant damage to your interior furnishings over time.

The Impact on Furniture and Belongings:

- Fading: One of the most noticeable effects of UV radiation is the fading of colours in furniture, carpets, and artwork. The vibrant hues of your sofas, rugs, and paintings can gradually lose their intensity, leaving them looking dull and aged.

- Material Degradation: Prolonged sun exposure can lead to the breakdown of materials such as wood, fabric, and plastics. This degradation weakens the structural integrity of your furniture, reducing its lifespan and aesthetic appeal.

- Heat Damage: UV rays also contribute to increased indoor temperatures, which can exacerbate wear and tear on household items. Electronics, in particular, are susceptible to heat damage, potentially shortening their functional lifespan.

Why Polycarbonate Awnings Are the Answer

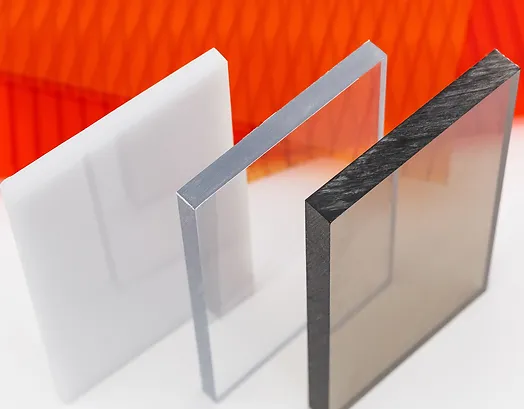

Polycarbonate is a lightweight, shatter-resistant plastic material renowned for its ability to block UV radiation. Polycarbonate window awnings act as a physical barrier, significantly reducing the amount of UV rays that reach your windows.

Additional Benefits

Polycarbonate awnings are not only effective but also durable and weather-resistant. They come in various styles and designs, allowing homeowners and business owners to choose options that complement their existing architecture while providing essential protection.

Benefits of Installing Polycarbonate Window Awnings

Furniture and Fabrics

Polycarbonate awnings can significantly slow down the fading and discolouration of furniture upholstery, carpets, and rugs. By blocking harmful UV rays, these awnings help maintain the original beauty and vibrancy of your interior decor. Additionally, they offer protection for valuable antique furniture and artwork displayed near windows.

Artwork and Photos

UV rays can cause fading and deterioration of photographs, paintings, and other artwork. Polycarbonate window awnings help preserve the vibrancy and value of your treasured pieces by shielding them from harmful radiation.

Electronics and Appliances

Sun exposure can also affect electronics and appliances near windows, such as TVs and computers, leading to potential heat and UV damage. Installing polycarbonate awnings can help protect these valuable items, ensuring their longevity and optimal performance.

Choose Polycarbonate Window Awnings from Canada Plastics and Belting Inc.

Polycarbonate window awnings offer a comprehensive solution to protecting your furniture and belongings from sun damage. By blocking harmful UV rays and reducing indoor heat, these awnings help preserve the integrity and aesthetics of your interiors.

If you’re looking to safeguard your home or office with the best UV protection, consider polycarbonate window awnings. Contact Canada Plastics and Belting Inc., a leading polycarbonate awnings supplier in Toronto, to learn more today.

Hygiene and safety stand as the cornerstones of quality and customer satisfaction in the world of food service. Among the myriad of tools and equipment that populate commercial kitchens, cutting boards are perhaps the most understated yet crucial for maintaining these standards. But they aren’t a one-size-fits-all type of product. Enter high-density polyethylene (HDPE) cutting boards, a superior choice for food service professionals, architects, interior designers, and homeowners alike.

Hygiene and safety stand as the cornerstones of quality and customer satisfaction in the world of food service. Among the myriad of tools and equipment that populate commercial kitchens, cutting boards are perhaps the most understated yet crucial for maintaining these standards. But they aren’t a one-size-fits-all type of product. Enter high-density polyethylene (HDPE) cutting boards, a superior choice for food service professionals, architects, interior designers, and homeowners alike.