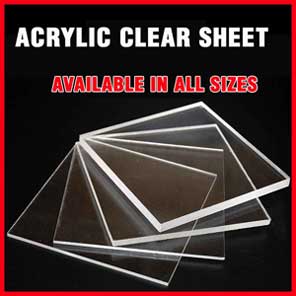

Acrylic sheets are some of the most commonly used plastic materials used in commercial, industrial, and residential construction projects. Often used as a strong replacement for glass, acrylic sheets can be transparent or opaque and they come in a variety of custom colours to match the aesthetic of the structure to which they’re being applied. They work as a solid alternative to glass—which is heavy, expensive, and extremely fragile.

Acrylic sheets are some of the most commonly used plastic materials used in commercial, industrial, and residential construction projects. Often used as a strong replacement for glass, acrylic sheets can be transparent or opaque and they come in a variety of custom colours to match the aesthetic of the structure to which they’re being applied. They work as a solid alternative to glass—which is heavy, expensive, and extremely fragile.

Contrary to glass, acrylic sheets are completely lightweight, affordable, and versatile. They can be cut, resized, or reshaped on the spot to fit specific structural parameters and dimensions whereas glass would need to be transported back and forth on and off the jobsite to make modifications. Naturally, people have a lot of questions for acrylic sheet suppliers in terms of how well their products work, cost, and whether they hold up for long periods of time. We have the answers.

1. What Is Acrylic Used for?

Applications for acrylic sheets can vary from home improvement to sporting equipment, aquariums, military technology, sculptures, fluorescent light fixtures, and so much more. Acrylic sheets are so durable and versatile that they serve a multitude of purposes depending on the specific application in question. When it comes to construction, for instance, acrylic sheets can replace glass windows and skylights. They’re easier and more lightweight to transport and install. Plus, acrylic sheets are not fragile like glass and won’t shatter if dropped. They’re completely scratch-, corrosion-, and UV-resistant.

2. Are Acrylic Sheets Expensive?

Technically, acrylic sheets have a higher upfront cost than traditional glass sheets would. But, it’s still a worthwhile alternative for a number of reasons. As mentioned, acrylic is lightweight, durable, and a lot easier to install than glass. Acrylic and glass also share a lot of similar qualities in the sense that they’re both transparent and they both let in a lot of natural lighting. The reason acrylic costs more is because it’s a lot stronger and more weather-, scratch-, and impact-resistant than glass. Plus, acrylic is likely to last longer than glass and can endure exposure to all kinds of weather and environmental elements without showing signs of degradation, so you’ll definitely get your money’s worth.

3. Is Acrylic Plexiglas Durable?

Yes, acrylic Plexiglas is incredibly durable, especially compared to glass. It’s also about 50% lighter in weight than glass, which is another reason why it’s the more preferable choice for various applications. Acrylic Plexiglas can be manufactured using a cast or extruded method (free-form). Either way, it’s incredibly durable and the chemical compounds (polymethyl methacrylate) used in the manufacturing process make it shatterproof as well as temperature-, weather-, and impact-resistant. Even if it does sustain damages or breaks, unlike glass, acrylic Plexiglas pieces would have dull edges, and this minimizes the risk of injury. This is an important safety feature that makes acrylic the perfect material for a variety of applications that require human contact and use.

4. What’s the Difference between Acrylic and Plastic?

Contrary to what a lot of people think, acrylic isn’t an alternative to plastic. Actually, it’s a type of plastic material. The main difference is that acrylic is an industrial-grade thermoplastic that’s typically formulated for applications that require the utmost durability, temperature, and impact-resistance. For instance, if you’ve ever watched a hockey game and you see the players body-checking one another into the baseboards, then you’ve seen acrylic plastic in action. The baseboards, which are made of acrylic sheets, are designed to be able to take a hit without cracking in freezing conditions.

5. Is Acrylic Better Than Glass?

Acrylic is the superior alternative material to glass for a number of reasons. As mentioned, acrylic is more durable while weighing half as much as its glass counterparts. This makes for seamless transportation and installation. Accidents and human errors can happen on construction sites. While they’re not ideal occurrences, having versatile materials on hand makes it a lot easier to fix mistakes. If glass gets damaged, it needs to be replaced and this can cause a lot of delays in an industry where time is money. Acrylic is a lot less likely to get damaged. Even if damages do occur, acrylic can be cut down to size and reshaped onsite to make it more suitable for the project.

6. Is Acrylic Stronger Than Plastic?

Acrylic is a type of plastic. In fact, it’s one of the most uniquely durable and versatile types of plastic material currently on the market, which is why it’s used for such a wide range of applications.

7. Is Acrylic Plastic Toxic?

While the final product itself isn’t toxic for human contact and use, the manufacturing process of acrylic plastic can admittedly be harmful to the environment and workers in the facility. Factory workers must wear protective gear to avoid coming into direct contact with acrylic plastic in its liquid form as it can release toxic fumes into the atmosphere. Still, this is nothing compared to the very toxic fumes released by other similar commercial and industrial building materials. Compared to other materials on the market, acrylic actually has a relatively low fume output and in its final form, it’s classified as a non-hazardous material by the Occupational Safety and Health Administration (OSHA).

8. Does Acrylic Get Discoloured After Too Much Sun Exposure?

Discolouration isn’t a concern for acrylic plastic because it’s formulated to withstand extensive sun and UV ray exposure. Acrylic plastic is derived from natural gasses, which makes it UV-resistant. This quality is the main reason why acrylic plastic is typically used for skylights, greenhouses, shed windows, and any other structures that need to sustain long-term sun exposure.

9. Is Clear Acrylic Weather-Resistant?

Clear acrylic sheets are incredibly weather-resistant. Like their colour counterparts, there’s absolutely no risk of discolouration due to extensive sun and UV ray exposure. These panels have a general lifespan of about 10+ years and can withstand all kinds of weather conditions including snow storms, heavy rain, strong winds, hail, and more.

10. How Many Different Types of Acrylic Sheets Are There?

There are three types of acrylic sheets currently available on the market:

- Extruded acrylic sheets

- Cell cast acrylic sheets

- Continuous cast acrylic sheets

Acrylic Sheet Distributors in Toronto and the GTA

Canada Plastics & Belting Inc. is one of the leading white acrylic sheet distributors and coloured acrylic sheet suppliers in the GTA. Our stockroom is full of a wide assortment of transparent and opaque acrylic plastic sheets that are suitable for a variety of applications. Contact us today to learn more.

From order picking to storing and organizing new inventory, continuous movement is one of the biggest constant traits of the supply chain industry. All of that movement often generates a lot of dust, dirt, and contaminants—it’s totally unavoidable. Without proper provisions in place, those contaminants can easily spread from one employee to another. Moreover, they can also be carried into areas that require high levels of sanitation and temperature control.

From order picking to storing and organizing new inventory, continuous movement is one of the biggest constant traits of the supply chain industry. All of that movement often generates a lot of dust, dirt, and contaminants—it’s totally unavoidable. Without proper provisions in place, those contaminants can easily spread from one employee to another. Moreover, they can also be carried into areas that require high levels of sanitation and temperature control.

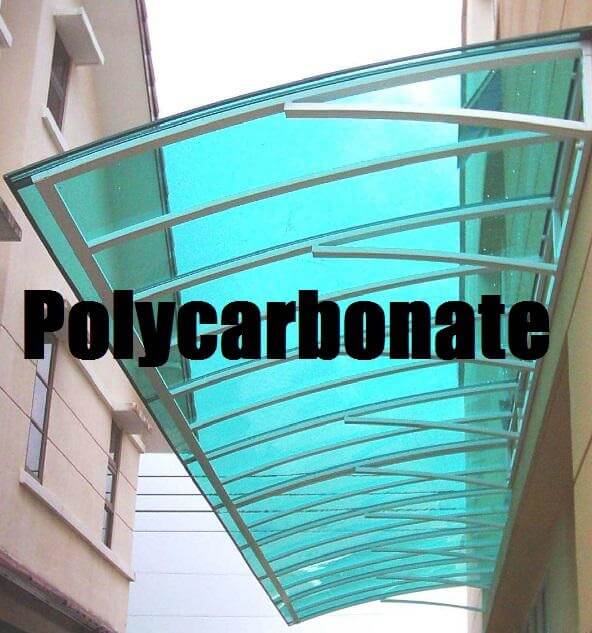

Polycarbonate is quickly becoming one of the most commonly used building materials in the professional and DIY construction industry. Even if you don’t know what polycarbonate is, the chances are very high that you’ve probably seen it used for a number of structures and construction projects over the past few years. Often used as a lightweight and more durable replacement for glass or standard plastic, polycarbonate has a lot of great qualities that make it a worthy contender for a substitute material for gazebo roof panels.

Polycarbonate is quickly becoming one of the most commonly used building materials in the professional and DIY construction industry. Even if you don’t know what polycarbonate is, the chances are very high that you’ve probably seen it used for a number of structures and construction projects over the past few years. Often used as a lightweight and more durable replacement for glass or standard plastic, polycarbonate has a lot of great qualities that make it a worthy contender for a substitute material for gazebo roof panels.

Over the past few years, polycarbonate has gradually become the go-to alternative building material to replace glass and acrylic for a number of reasons. It’s an extremely versatile material that boasts many different qualities that make it suitable for a variety of construction applications, including roofing. Constructed using thermoplastic polymer, polycarbonate roofing panels are completely transparent and durable, which makes them the ideal choice for greenhouses, skyscrapers, and automobiles. Keep reading to learn all about the benefits of polycarbonate gazebo roof panels for your next professional or DIY construction project.

Over the past few years, polycarbonate has gradually become the go-to alternative building material to replace glass and acrylic for a number of reasons. It’s an extremely versatile material that boasts many different qualities that make it suitable for a variety of construction applications, including roofing. Constructed using thermoplastic polymer, polycarbonate roofing panels are completely transparent and durable, which makes them the ideal choice for greenhouses, skyscrapers, and automobiles. Keep reading to learn all about the benefits of polycarbonate gazebo roof panels for your next professional or DIY construction project.

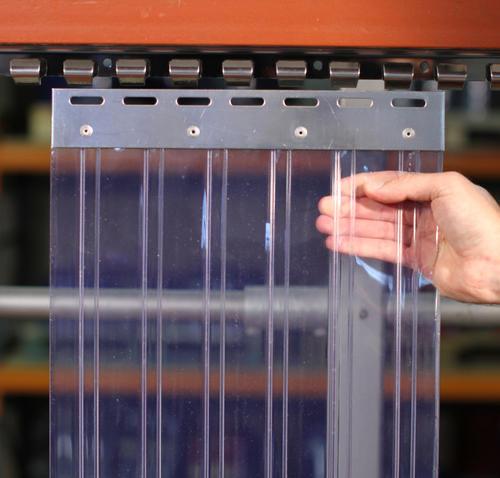

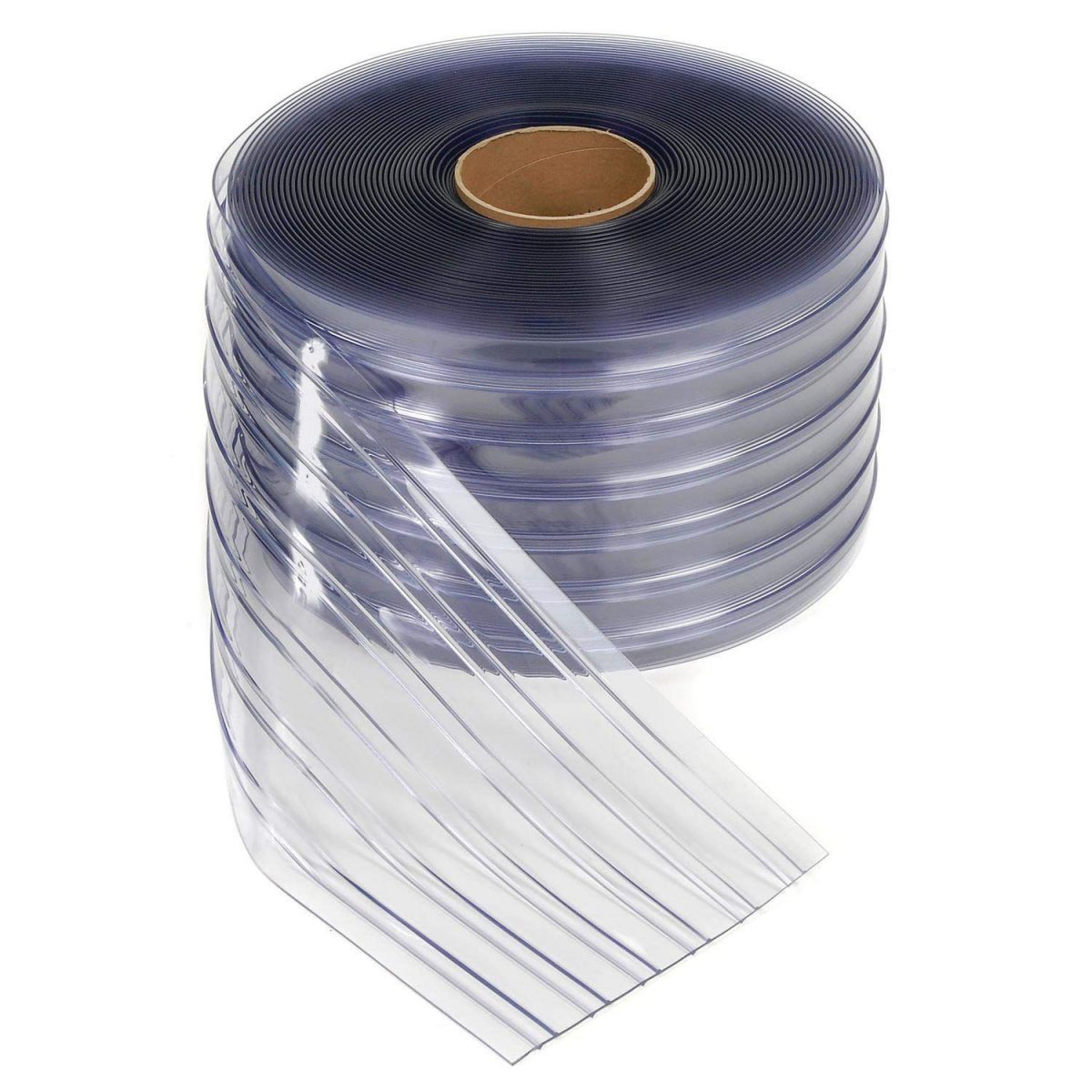

Chances are that if you’ve ever been in a retail store, manufacturing plant, or a warehouse, you’ve probably seen or come in contact with a PVC strip door curtain. You might not have thought twice about it at the time, but PVC strip curtains can actually come in handy if you happen to own or work for a manufacturing or distribution business. PVC is a type of industrial or commercial-grade plastic that’s extremely durable and versatile, making it the perfect choice for any type of high-traffic fast-paced environment that involves a lot of maneuvering and transporting of products.

Chances are that if you’ve ever been in a retail store, manufacturing plant, or a warehouse, you’ve probably seen or come in contact with a PVC strip door curtain. You might not have thought twice about it at the time, but PVC strip curtains can actually come in handy if you happen to own or work for a manufacturing or distribution business. PVC is a type of industrial or commercial-grade plastic that’s extremely durable and versatile, making it the perfect choice for any type of high-traffic fast-paced environment that involves a lot of maneuvering and transporting of products.

As far as roofing materials go, polycarbonate is arguably one of the most cost-effective, lightweight, affordable, and flexible choices available. It’s also more commonly used for roofing than most people think. People typically assume that all roofs are made up of clay, cement, asphalt, wood, or slate. Hardly anyone ever ventures to guess that a roof could consist of polycarbonate roofing panels.

As far as roofing materials go, polycarbonate is arguably one of the most cost-effective, lightweight, affordable, and flexible choices available. It’s also more commonly used for roofing than most people think. People typically assume that all roofs are made up of clay, cement, asphalt, wood, or slate. Hardly anyone ever ventures to guess that a roof could consist of polycarbonate roofing panels.