Invented in the early 1900s, plexiglass has a long and storied history. Its main claim to fame is that it’s a stronger and more resilient glass substitute that mimics the appearance of its predecessor and nothing else. Plexiglass and glass are both available in a variety of transparency levels and aesthetic designs, but the similarities between the two ends there. Originally, plexiglass sheets were designed to serve as a lightweight alternative to glass for a variety of applications. As a result, its popularity across various industries has only seen continuous growth over the years.

Invented in the early 1900s, plexiglass has a long and storied history. Its main claim to fame is that it’s a stronger and more resilient glass substitute that mimics the appearance of its predecessor and nothing else. Plexiglass and glass are both available in a variety of transparency levels and aesthetic designs, but the similarities between the two ends there. Originally, plexiglass sheets were designed to serve as a lightweight alternative to glass for a variety of applications. As a result, its popularity across various industries has only seen continuous growth over the years.

What Is Plexiglass?

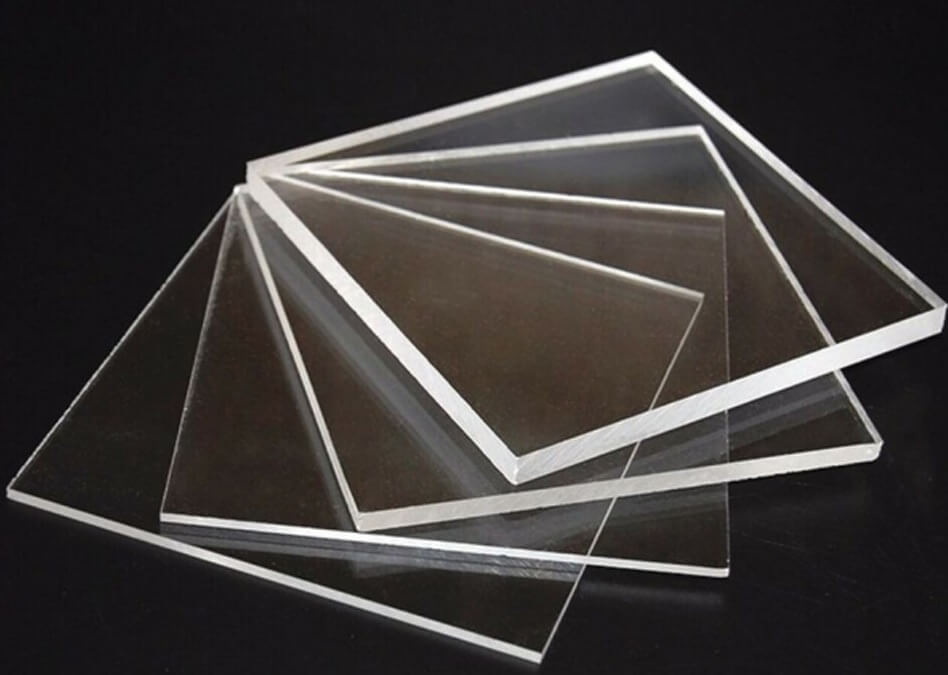

Plexiglass is a thermoplastic material that has the capacity to withstand a wide range of extreme temperatures and environmental conditions. Composed of polymethyl methacrylate and has a melting point of 160°C or 320°F. It’s also commonly referred to as acrylic or acrylic glass and is typically manufactured in large transparent and flat sheets. However, plexiglass can also be frosted or opaque. Plexiglass is the generic term for this material, whereas Plexiglas® is an official brand name.

When to Use Plexiglass

There are a number of notable benefits to using plexiglass for various commercial and residential construction projects or other types of applications where glass would traditionally be used. Plexiglass is a close second to glass and is even a better alternative in many ways. Here are a few reasons to use plexiglass sheets instead of glass for your next big or small project.

Cost Savings

Not only are plexiglass sheets cheaper and easier to manufacturer than glass, they’re also incredibly lightweight which makes transportation a breeze. Less weight means plexiglass sheets are easier to carry and can often be carried by one person. It also reduces the amount of weight on transport vehicles, which improves fuel efficiency and cost savings for your business.

Safety and Durability

Plexiglass sheets have been used as dividers to safeguard food displays and hot tables in restaurants, buffets, and bakeries for decades. The onset of the COVID-19 pandemic expanded the use of plexiglass protective dividers and sneeze guards to a variety of other industries and public settings. Now it’s widely used in more eateries, medical centers, retail stores, and grocery stores to help prevent the spread of viral transmissions. The reason plexiglass sheets are used as sneeze guards instead of glass is because they’re easy to sanitize and more impervious to damages like scratches or dents.

The lightweight nature of plexiglass sheets also makes them a lot easier to carry and install almost anywhere.

Versatility and Ease of Use

Unlike glass, plexiglass sheets are incredibly versatile and easy to use in virtually any indoor or outdoor setting. Plexiglass has garnered a number of different uses over the years thanks to its unmatched durability and versatility. During and after the manufacturing process, plexiglass can be customized to suit the practical requirements of all applications for which it’s used.

Since plexiglass is typically delivered in large sheets, it can be cut down to size on construction sites prior to installation. That way, you can always be sure that you have the correct size and shape needed for your specific project. Its incredibly lightweight design also makes it easier to transport large quantities of plexiglass at a time. So, even if you make a mistake in the reconfiguration process, you can always order extra plexiglass sheets and use the leftovers for other projects. The fact that plexiglass sheets are so lightweight also makes it easier to take them in and out of storage as needed.

Light Transmission Capabilities

Plexiglass has light transmission and distribution capabilities that are comparable to glass. In fact, plexiglass has become the go-to material of choice for a lot of commercial and residential contractors for this reason along with the fact that it’s so lightweight and easy to install. Plexiglass sheets also have exceptional UV blocking capabilities that protect structural interiors and those who use them.

Plexiglass sheets are suitable fixtures for any structures that require a great deal of steady light transmission and even distribution throughout the premises. Structures such as homes, greenhouses, apartment buildings, and storefronts can all reap the benefits of plexiglass instead of the traditional glass.

Applications for Plexiglass Sheets

Given all of their many attributes, plexiglass sheets have become increasingly ubiquitous across commercial, residential, and industrial applications over the years. Most often, plexiglass sheets are used for windowpanes, but their uses have expanded far beyond standard construction elements. In light of the pandemic, more and more businesses have opted to use plexiglass sheets as sneeze guards or dividers to create separation between customers and employees. Other common uses of plexiglass sheets include the following.

Skylights

As mentioned, plexiglass sheets provide excellent light transmission, distribution, and UV protection all at the same time. Spaces that are lacking natural lighting can benefit greatly from skylights made out of plexiglass. It’s an incredibly durable material that can withstand virtually all external and internal environmental elements including snow, rain, wind, and even various temperatures.

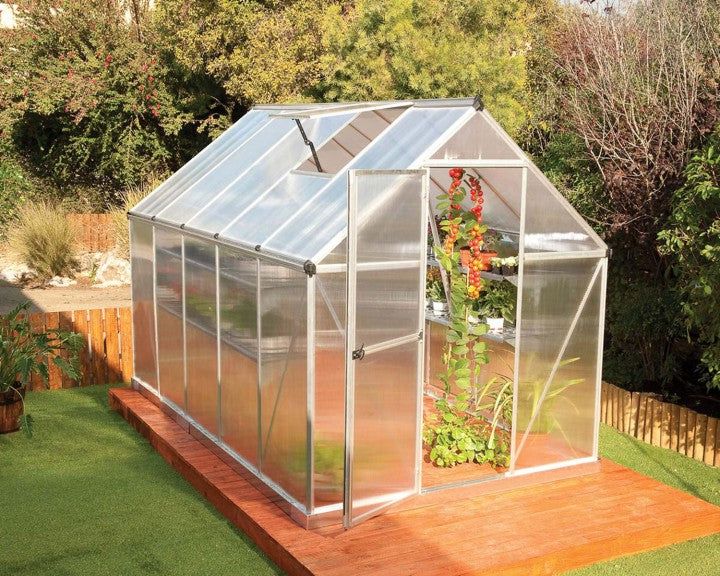

Greenhouses

Plexiglass is also perfectly suited for use in greenhouses. Not only does it distribute light evenly so that every plant gets the nutrients it needs from the sun, but it also blocks out harmful UV rays and protects the plants from external elements.

Print Signs, Art, and Advertising

Plexiglass has turned the art of print media on its head. In the past, plexiglass was only used as a protective external casing for static paper or canvas signs, prints, and pieces of advertising to prevent damages. While plexiglass is still used as a protective casing for various types of print advertising and art, its use has evolved significantly.

Now, many artists and advertisers are actually printing their work and brand messaging directly on plexiglass platforms. This is a much more space, time, and cost-efficient option for individual artists and large brands alike because it reduces the amount of materials used for each piece without compromising on durability and quality.

Plexiglass Suppliers in the GTA

Canada Plastics & Belting Inc. is one of the top plexiglass distributors in Toronto and the GTA. We have a wide inventory of various types of plexiglass products that come in various shapes, colours, and transparencies. Choose from the products we have in stock or place customized orders that are specific to the requirements of your commercial or residential project. Contact us today to learn more about our products.

Glass is bulky, heavy, and extremely fragile. Plexiglass, on the other hand, has all of the same aesthetic appeal and functionality of glass without its negative traits. It’s extremely versatile and can be used for numerous different residential and commercial construction projects. Considering plexiglass Acrylic Glass Sheets is one of the most versatile glass substitutes on the market, it’s also surprising that it happens to be an extremely affordable commonly used building material. In fact, you’ve most likely seen a structure featuring plexiglass and automatically assumed it was glass. Keep reading to learn about the most common and best uses of plexiglass.

Glass is bulky, heavy, and extremely fragile. Plexiglass, on the other hand, has all of the same aesthetic appeal and functionality of glass without its negative traits. It’s extremely versatile and can be used for numerous different residential and commercial construction projects. Considering plexiglass Acrylic Glass Sheets is one of the most versatile glass substitutes on the market, it’s also surprising that it happens to be an extremely affordable commonly used building material. In fact, you’ve most likely seen a structure featuring plexiglass and automatically assumed it was glass. Keep reading to learn about the most common and best uses of plexiglass.

Although PVC strip curtains and doors are built to last a long time in all kinds of industrial settings such as warehouses and distribution centers, they will eventually start to show signs of wear and tear. Years of constant rough usage including pushing, pulling, and direct contact with industrial machines all contribute to the deterioration and damage of your PVC strip warehouse curtains. The time will come when they’ll need to be replaced. Keep reading to learn about the different types of damages that indicate it’s time to replace your PVC strip curtains.

Although PVC strip curtains and doors are built to last a long time in all kinds of industrial settings such as warehouses and distribution centers, they will eventually start to show signs of wear and tear. Years of constant rough usage including pushing, pulling, and direct contact with industrial machines all contribute to the deterioration and damage of your PVC strip warehouse curtains. The time will come when they’ll need to be replaced. Keep reading to learn about the different types of damages that indicate it’s time to replace your PVC strip curtains.

Invented in the early 1900s, plexiglass has a long and storied history. Its main claim to fame is that it’s a stronger and more resilient glass substitute that mimics the appearance of its predecessor and nothing else.

Invented in the early 1900s, plexiglass has a long and storied history. Its main claim to fame is that it’s a stronger and more resilient glass substitute that mimics the appearance of its predecessor and nothing else.

As the COVID-19 pandemic rages on with new variants of the virus emerging, restaurants need to remain hyper-vigilant when it comes to imposing health and safety precautions. Providing hand sanitizing stations and asking customers to maintain physical distance and wear masks in common areas has become standard operating procedures for all dine-in restaurants and businesses in general. But with the Omicron variant spreading rapidly, it’s time for restaurants to take it a step further. Grocery stores have long since adopted the use of sneeze guards to protect employees and customers alike. Now it’s time for

As the COVID-19 pandemic rages on with new variants of the virus emerging, restaurants need to remain hyper-vigilant when it comes to imposing health and safety precautions. Providing hand sanitizing stations and asking customers to maintain physical distance and wear masks in common areas has become standard operating procedures for all dine-in restaurants and businesses in general. But with the Omicron variant spreading rapidly, it’s time for restaurants to take it a step further. Grocery stores have long since adopted the use of sneeze guards to protect employees and customers alike. Now it’s time for

Polycarbonate Corrugated Panels is one of the most versatile and commonly used building materials currently on the market. Horticulturists, in particular, have made excellent use of multiwall sheets for greenhouses thanks in large part to their numerous qualities.

Polycarbonate Corrugated Panels is one of the most versatile and commonly used building materials currently on the market. Horticulturists, in particular, have made excellent use of multiwall sheets for greenhouses thanks in large part to their numerous qualities.

Polycarbonate roofing panels have been around in the construction industry for decades, but have only recently started gaining popularity for various design and building applications such as greenhouse structures. The reason for its slow ascent into mainstream uses for gazebo roofing is because most people like to stick to old faithful: glass. What they don’t realize is that there are a lot of great benefits to using greenhouse polycarbonate sheets instead. Unfortunately, there’s a lot of misinformation going around about the efficacy of greenhouse polycarbonate sheets and how they work. To help clear the air, here are some of the biggest myths and misconceptions that you should know about so you can make a more informed decision.

Polycarbonate roofing panels have been around in the construction industry for decades, but have only recently started gaining popularity for various design and building applications such as greenhouse structures. The reason for its slow ascent into mainstream uses for gazebo roofing is because most people like to stick to old faithful: glass. What they don’t realize is that there are a lot of great benefits to using greenhouse polycarbonate sheets instead. Unfortunately, there’s a lot of misinformation going around about the efficacy of greenhouse polycarbonate sheets and how they work. To help clear the air, here are some of the biggest myths and misconceptions that you should know about so you can make a more informed decision.

If you have worked or visited a factory recently you may remember some industrial barriers that were installed over there. These barriers are called

If you have worked or visited a factory recently you may remember some industrial barriers that were installed over there. These barriers are called

Roofing is one of the most important components when it comes to commercial and residential property construction. These days, there’s no shortage of roofing system material options to choose from. Among the many options are wood, clay, stone, metal, and polycarbonate plastic.

Roofing is one of the most important components when it comes to commercial and residential property construction. These days, there’s no shortage of roofing system material options to choose from. Among the many options are wood, clay, stone, metal, and polycarbonate plastic.