Sub-Categories

-

FRP WALL SHEETS (Copy)

Request QuoteFIBERGLASS RE-INFORCED PLASTIC

Standard & Flat Sheet FRP Wall Panels

Made for Beauty, Made for Ease, Made for LifeFor years, flat sheet FRP Wall Panels have grown a reputation for affordability, durability, and ease of installation in applications ranging from restrooms and kitchens to commercial interiors. Today, fiberglass wall panels are so much more!

We offer more customization options than any other manufacturer of fiberglass panels. Our FRP wall panels offer architects, builders, and designers a wall covering that not only provides all the characteristics they need, but also is suitable for virtually any interior application.

When other FRP manufacturers can’t or won’t, ours will

When you are shopping for fibreglass reinforced plastic (FRP) wall panels, wainscoting or wall cladding, ease of installation and durability are a basic requirement. However, for many out there searching, finding the right colour, finish, thickness or fire rating is where the search can get tough.

Flat sheet FRP wall panels solve that problem with more stocked standard colours, finishes, and sheeting options than any other FRP manufacturer, and a world of possibilities with value-added services like custom cuts, imaging, sublimating, laminating and much more.

Sizing Information

Standard Thickness: : 2mm (.08”)

Custom Thickness: FRP wall panels as thin as .045” or as thick as .170″ (pebbled) are possible

Widths: 60″ (5’) and 48″ (4’) are standard.Length: Cuts come in 8′, 9′, 10′ and 12′ standard lengths, with lengths up to 165ft available on rolls or coils. We can also cut to the length you need.

Fire Ratings

General purpose; Class C (FS=120 SD=290)

Low Flame, Class A LF (FS=25 and SD=450)

Low Flame and Smoke; Class A LF&S (FS= 20 SD=100)Vinyl Molding Profiles

Matching vinyl moldings for our standard stocked colours are available including inside and outside corners, as well as end caps and dividers in 8’ and 10’ (12’= white or special order only) lengths to handle any Kal-Lite FRP wall panels.

Aluminum Molding Profiles

We also offer the standard molding profiles in Aluminum with an anodized gray finish.Alternative Molding (Larger) Profiles

We do offer larger inside & outside corner (1 ½” x 1 ½”) profiles as well, for some of our more popular colors.Reasons to Use FRP Paneling/FRP Wallboard

- Non-porous

- Resin rich

- Extremely resistant to moisture

- Scratch resistant

- Impact resistant

- Lightweight

- Flexible

- More economical than other construction materials

- Mold and rust-resistant

- Aesthetically pleasing and available in a variety of colours and textures

- “Class A” Fire-rated FRP Panels available for medical and educational facilities

- Easy to install

- Resistant to odors

- Corrosion resistant

- Meets or exceeds USDA standards

Tips for Installing FRP Panels

The FRP panels must be stored at a temperature above 50 degrees for 24 hours before installation as they can contract and expand, causing them to bubble or buckle in areas after installation. Storing the FRP panels inside the area where they are to be installed is preferable. Always store on a flat surface. Installing FRP on flat, prepared, un-sanded walls will help prevent bubbles. Water-based adhesive should be applied with a trowel to the back of the wallboard after the divider piece is adhered using silicone. We suggest using Franklin Titebond water-based adhesive in standard applications using drywall, dura rock, or plywood as a substrate. Concrete block walls may require advanced polymer adhesive. It is imperative to measure and cut/route out for any plumbing fixtures or electrical boxes. When cutting Fiberglass Reinforced Plastic, the installer should subtract ½” from the vertical measurement and 1/8” for expansion around pipes and other projections. J-mould may be required at the base depending on the application, and it may also be used at the ceiling if installation takes place after the ceiling is installed. Make sure to clean all excess adhesive and silicone from the panels immediately.

Tools needed for Installing FRP Sheets

- Eye protection

- Filter masks should be worn while cutting FRP panels

- Shears

- Drill

- Trowel

- Carpenter’s square

- Hammer

- Tape measure

- Level

- Mouldings

- Fasteners if using

Cleaning FRP panels

Use a mild soap or detergent. FRP board is very easy to clean. Power washers may be used for stubborn staining, but abrasive cleaners should not be used.

https://youtu.be/0OzofHT83fc

For more information:

Our address: Canada Plastics & Belting Inc 100 Dynamic Drive Units 5-7 Scarborough ON M1V5C1

Tel: +1 416 291 3036

-

G1 10MM X 50MM X 70A Natural White

-

G1 10MM X 50MMX 70A Shore Transparent White

-

G1 5MM X 30MM White 70A Shore

-

G1 5MM X 30MM X 75A Shore Green

-

G1 8MM X 50MM X 70A Shore Natural White

-

G1 8MM X 60MM X 55A SHORE NATURAL WHITE

-

G1 8MM X 60MM X 65A Shore Red Watts

-

G1 8MM X 60MM X 70A Shore Natural White

-

G1 9MM X 50MM X 65A Shore Red Flat

-

G1 9MM X 50MM X 70A Shore White

-

G1 9MM X 50MM X 75A Shore Green

-

G1 9MM X 50MM X 90A Shore White

-

G3 5MM X 30MM X 65A Shore Red

-

G3 5MM X 30MM X 80A Shore Dark Blue

-

G3 8MM X 60MM X 65A Shore Red

-

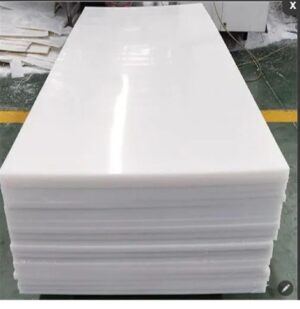

HDPE CUTTING BOARD

Request QuoteHigh-Density Polyethylene (HDPE) Cutting Boards

In the world of culinary arts, the importance of a reliable cutting board cannot be overstated. Whether you’re dicing fresh vegetables, slicing tender meats, or chopping an array of spices, the surface you choose directly impacts food safety, kitchen hygiene, and even the longevity of your precious knives. For restaurant owners, managers, and professional chefs seeking an upgrade from traditional materials, the high-density polyethylene (HDPE) cutting board presents a superior choice.

The benefits of HDPE cutting boards range from excellent durability and ease of cleaning to heat resistance and compliance with FDA regulations. Canada Plastics and Belting Inc. is a trusted supplier of top-quality HDPE cutting boards for commercial kitchens in Toronto and the GTA.

Key Features

HDPE cutting boards have emerged as a staple in both commercial and home kitchens, thanks to their myriad advantages over conventional materials like wood or bamboo.

- Safe for Food Contact: Our HDPE cutting boards are FDA-compliant, ensuring safe food preparation and peace of mind.

- Superior Durability: HDPE is known for its exceptional strength and resistance to warping, cracking, and chipping. These cutting boards can withstand everyday use and last for years.

- Gentle on Knives: The slightly textured surface prevents knives from dulling while providing a secure grip for chopping.

- Easy to Clean: HDPE’s nonporous surface inhibits bacterial growth and allows for effortless cleaning with soap and water. It is also dishwasher-safe for ultimate convenience.

- Sanitary Choice: Unlike wood or bamboo boards, HDPE does not harbour bacteria or require special oils for maintenance.

- Heat Resistant: These boards withstand high temperatures without warping or compromising integrity, making them suitable for hot food preparation.

HDPE Cutting Board Properties

Understanding the technical specifications helps illustrate why HDPE cutting boards stand out:

- Tensile Strength: 4,000 psi

- Flexural Modulus: 200,000 psi

- Izod Impact (Notched): 1.3 ft-lbs/in of notch

- Heat Deflection Temperature @66 Psi: 172 ºF

- Water Absorption (Immersion 24 Hours): 0.1%

- Coefficient of Linear Thermal Expansion: 7 in/in/ºFx10-5

Top HDPE Cutting Board Applications

HDPE cutting boards are versatile, serving various applications across the culinary industry:

- Home Kitchen: Ideal for daily meal preparation, slicing, dicing, and chopping a variety of ingredients.

- Commercial Kitchens: Trusted by professional chefs and food service establishments for their durability and hygiene standards.

- Food Processing: Used in food processing facilities for meat, poultry, and seafood preparation.

- Catering and Events: Perfect for catering events, buffets, and food presentations due to their sleek and professional appearance.

- Outdoor Grilling: Convenient for outdoor grilling and BBQs, providing a reliable surface for food preparation.

Available HDPE Cutting Board Options

Understanding the needs of various kitchen environments, we offer cutting boards in multiple thicknesses and sizes, including standard and custom cut-to-size options to fit any counter or workstation perfectly.

Why Choose Canada Plastics and Belting Inc.?

At Canada Plastics and Belting Inc., we are committed not just to delivering quality kitchen tools, but also to enhancing the efficiency and safety of your culinary operations.

- Quality Assurance: Our cutting boards undergo rigorous quality control measures to ensure superior performance and longevity.

- Customer Satisfaction: We prioritize customer satisfaction, providing prompt assistance and support to address any inquiries or concerns.

- Environmentally Friendly: Committed to sustainability, our HDPE cutting boards are recyclable and eco-friendly.

Upgrade your kitchen with a Canada Plastics &and Belting Inc. HDPE cutting board! Contact us online or by phone, or visit our store today for more information.

- Phone Number: (416) 291-3036

- Email: info@canada-plastics.com

-

HDPE Sheets

Request QuoteHigh-Density Polyethylene (HDPE) Sheets

High-density polyethylene (HDPE) sheets are a versatile thermoplastic formed from a chain of ethylene molecules. Often used in industrial settings, they have forged their way into commercial and residential landscapes due to their robust, weather-resistant, and chemically inert makeup. Interior designers, homeowners, and DIY enthusiasts are increasingly discovering the potential these sheets hold for enhancing their designs and projects.

Key Features

Canada Plastics and Belting Inc.’s HDPE sheet features:

- Superior Durability: Crafted from HDPE, our sheets offer exceptional strength and durability, ensuring longevity in various applications.

- Versatility: HDPE sheets from Canada Plastics are versatile and adaptable, suitable for a wide range of industrial, commercial, and residential applications.

- Chemical Resistance: Resistant to chemicals, acids, and solvents, our HDPE sheets provide reliable performance even in challenging environments.

- Weatherproof Effects: With excellent weather resistance, our sheets withstand harsh outdoor conditions, making them ideal for outdoor signage, construction projects, and more.

- Ease of Fabrication: HDPE sheets are easy to cut, weld, and shape, allowing for seamless customization to fit specific project requirements.

- FDA Compliance: Our HDPE sheets meet FDA regulations for food contact, making them ideal for food processing, packaging, and other applications requiring safe contact with edibles.

HDPE Properties

Core properties of our HDPE sheets include:

- Tensile Strength: 4,000 psi

- Flexural Modulus: 200,000 psi

- Izod Impact (Notched):3 ft-lbs/in of notch

- Heat Deflection Temperature @66 Psi: 172 ºF

- Water Absorption (Immersion 24 Hours):1%

- Coefficient of Linear Thermal Expansion: 7 in/in/ºFx10-5

Top HDPE Sheet Applications

The applications of HDPE sheets span a wide gamut, with some of the most common including:

- Chemical tanks

- Cutting boards for food preparation

- Water pipe flanges (HDPE pipe grade)

- Outdoor and indoor playground systems

- Marine construction (pile guards, bumpers, anti-skid surfaces)

- Orthotics and prosthetics

- Light-duty tank, chute, and bin linings

- Truck liners

- Outdoor cabinetry and furniture

Available Thickness and Sizes

Canada Plastics carries a variety of colours and sizes in HDPE sheets, ensuring that your project’s specific needs are met with precision. From a thickness range of 3 mm to 75 mm, our HDPE sheets can be custom-cut to your required dimensions, giving you the flexibility to design without limits. The standard size is 48” x 96”.

Thickness Size Color 3mm 48” x 96” Natural 4.5mm 48” x 96” Natural 6mm 48” x 96” Natural 10mm 48” x 96” Natural 12mm 48” x 96” Natural 16mm 48” x 96” Natural 20mm 48” x 96” Natural 25mm 48” x 96” Natural 32mm 48” x 96” Natural 40mm 48” x 96” Natural 50mm 48” x 96” Natural 75mm 48” x 96” Natural Why Choose Canada Plastics and Belting Inc.?

Choosing the right HDPE sheets for your project is a crucial decision. Canada Plastics and Belting Inc. is an ideal partner in your plastic endeavours, offering:

- Quality Assurance: We adhere to stringent quality control measures to deliver products that meet the highest standards.

- Customer Satisfaction: Focusing on customer satisfaction, we strive to provide exceptional service and support at every stage.

- Expertise: Backed by years of experience and expertise in the plastic industry, we are your trusted partner for all plastic solutions.

Contact us today to discuss your HDPE sheet requirements. Our team of experts can help you choose the right product for your application.

-

L-Shape 8MM X 60MM X 70A Shore

-

Lohmann 2.0

-

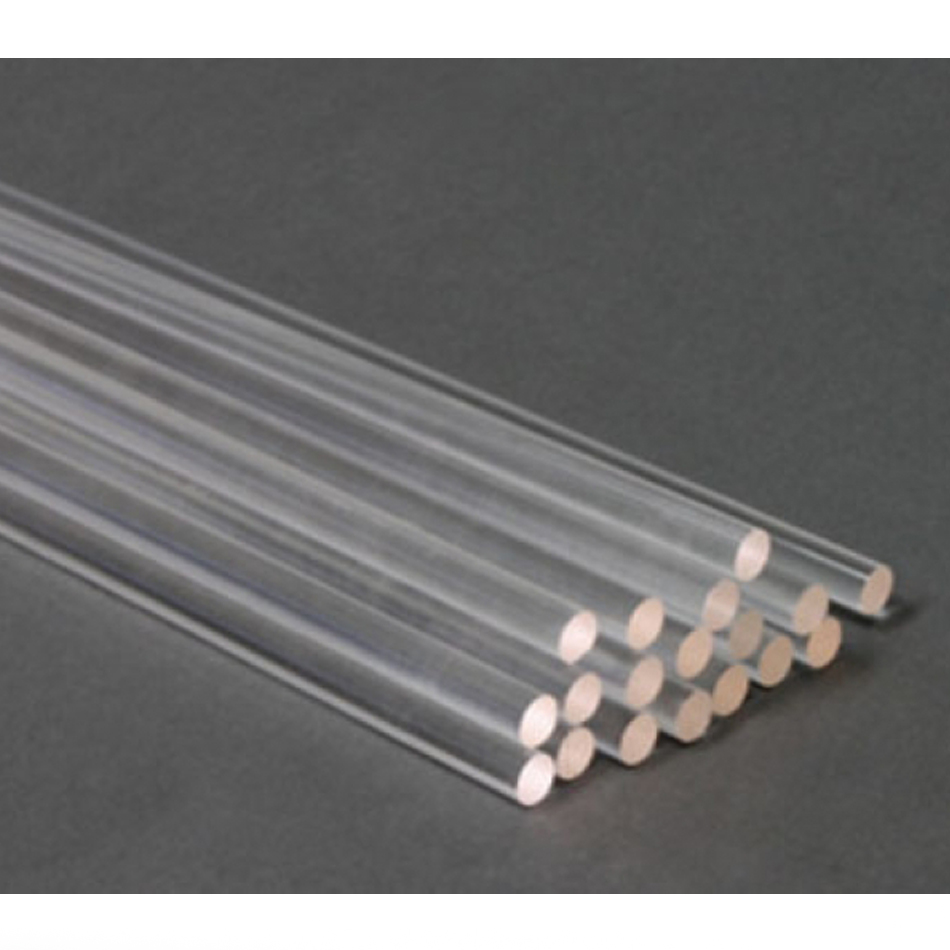

Nylon Rods

Request QuoteNylon is the Generic name for a family of Long Chain Polymeric Amides. Ganeral Characterstics of the nylons include toughness, strength, abrasion and fatigue resistance

Nylon is the Generic name for a family of Long Chain Polymeric Amides. Ganeral Characterstics of the nylons include toughness, strength, abrasion and fatigue resistance, low coefficient of friction, resiliency and heat resistance. Many of these properties can be enhanced by the addiction of filler such as molybdenum disulphide. Nylons are resistant to hydrocarbons, alkalies, keytones and esters.

Key feature And Benefits:

- Very High Sliding Properties

- High mechanical Strength

- Good fatigue resistance

- Excellent wear Resistance

- Absorbs moisture, therefore, cannot be used underwater

- High Impact Strength and toughness

- Low Power Factor Requirements

- High wear Resistance

Following Sizes are Available in stock:

- 1/2″ x 1mt long

- 5/8″ x 1mt long

- 3/4″ x 1mt long

- 1″ x 1mt long

- 1-1/4″ x 1mt long

- 1-1/2″ x 1mt long

- 2″ x 1mt long

- 2-1/2″ x 1mt long

- 3″ x 1mt long

- 3-1/2″ x 1mt long

- 4″ x 1mt long

Other sizes are available upon request

For more information:

Our address: Canada Plastics & Belting Inc 100 Dynamic Drive Units 5-7 Scarborough ON M1V5C1

Tel: +1 416 291 3036

-

P0 5MM X 25MM X 80A Shore Dark Blue Fimor

-

P0 5MM X 30MM 65A Shore Red Fimor

-

P0 5MM X 30MM 75A Green Fimor