Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

Plastic sheets are now used to replace glass in both residential and commercial projects. Lexan and acrylic are the most common plastic sheets on the market today. But why are Lexan sheets so popular? Here are answers to seven frequently asked questions about Lexan sheets.

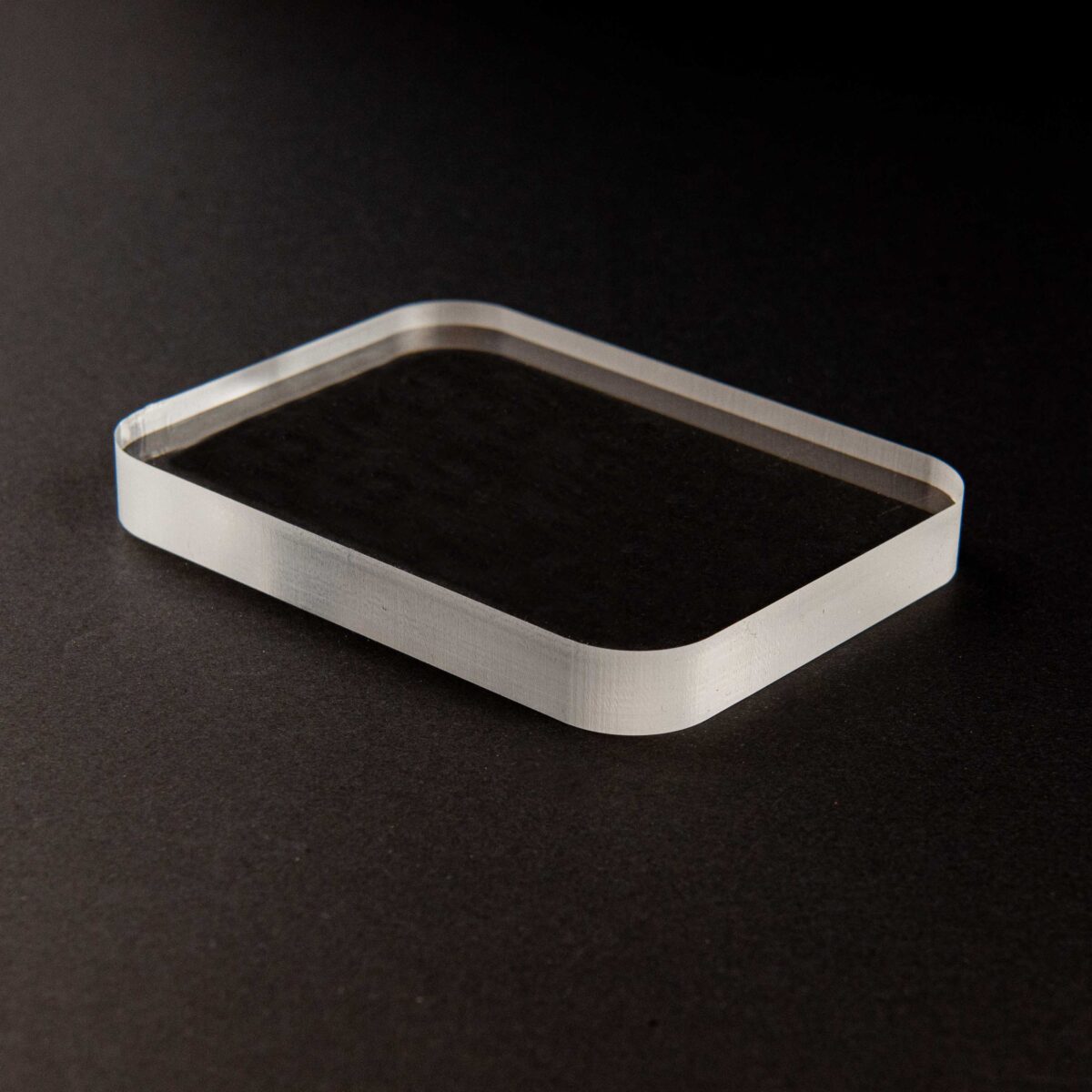

1. What Are Lexan Sheets?

Lexan is a trademarked name for polycarbonate sheeting manufactured by General Electric. Lexan can be anything from 0.75 mm (0.03 inch) to 12 mm (0.47 inch) thick. General Electric introduced Lexan in 1960, but the material is now manufactured by SABIC in Riyadh, Saudi Arabia.

When it comes to polycarbonate sheeting, Lexan is among the most well-known names in the industry. It is six times lighter than glass and has a high impact resistance. Not only is it low in flammability and thermoformable, it is also flame retardant.

2. Is Lexan and Polycarbonate the Same Thing?

Lexan and acrylic are also brand names for polycarbonate. Lucite is another name for acrylic.

But are Lexan and acrylic the same? No, they are not. People, especially DIYers mix up the two plastic sheets since they have similar properties.

Similarities

Both acrylic and polycarbonate are significantly more impact-resistant than glass, yet they are much stronger and weigh less. In addition, they are both easy to clean and have similar flexural strengths.

Acrylic and polycarbonate are both shatterproof, meaning that they break into a few bigger chunks unlike glass that is brittle and has no elasticity and can easily shatter into pieces. It is safe to say that both materials are much safer than glass.

Differences

While the two materials have some characteristics, there are also important distinctions. Their strengths and weaknesses also make them useful for different applications.

- Impact resistance: Acrylic is ten times more resistant to impact than glass is. However, the impact resistance of polycarbonate is 250 times that of glass. In other words, polycarbonate is stronger, which is why it is often used as a weatherproof glazing material and bulletproof glass.

- Cost: In comparison to acrylic, polycarbonate is more expensive. Acrylics, in contrast to polycarbonate, keep their high-quality appearance even after being heated and molded.

- Durability: Given its superior durability to acrylic, polycarbonate is the best material for bulletproof windows and other highly demanding usage. While its gloss surface and increased transparency make acrylic the superior material for display cases, its susceptibility to cracking makes it less desirable than polycarbonate because polycarbonate is more prone to scratch than crack.

3. Is Lexan Sheet Hard to Cut?

Lexan is quite simple to cut. It can be cut with either a circular saw or a jigsaw. When cutting longer polycarbonate lengths, a circular saw is recommended.

Note: If using a jigsaw, hold the sheets firmly in place while sawing to ensure a clean cut. Placing glue clamps on the sheet can help keep it from sliding up and down while sawing.

Even a newbie DIYer can easily cut a Lexan sheet by following these simple steps:

- Install a 1/16-inch laminate blade on a table saw. Raise the saw blade 1/2 inch above it

- Measure and tape the sawblade’s path across the Lexan. This ensures the saw blade cuts the tape lengthwise.

- Set the fence. The blade should cut down the tape line’s center. Tape prevents Lexan chips. If there are no tapes available, wearing safety goggle is recommended to prevent chips from entering the eyes.

- Start the saw. Hold the sides of the Lexan and slide it slowly into the blade.

- Push Lexan past the blade. If the Lexan starts to smoke, reduce the speed until it stops, and then continue to press until the Lexan clears the blade on the other side and take t ape.

4. How Do You Get Scratches Out of a Lexan Sheet?

When scratches are noticed on Lexan sheets, heat guns can be used to get rid of them. To remove scratches from a Lexan sheet, follow these instructions.

- Clean the Lexan surface.

- Apply heat to the scratched area using the heat gun at the recommended heat setting.

- To ensure consistent heat, move the heat gun up and down the scratched area at a constant rate. Repeated action can cause melting, so make sure it isn’t done for too long and that the gun isn’t too hot.

- Leave to cool and smoothen the uneven parts with sandpaper, then clean again.

5. Can You Bend the Lexan Sheet?

Polycarbonate is a strong plastic sheet that bends easily without breaking. It is much easier to bend than acrylic. Due to its elasticity, it may be bent hot or cold, though, cold bending is more common because it is way easier, especially for DIYers.

6. What Are the Benefits of Lexan Polycarbonate Sheets?

Lexan polycarbonate sheets have many benefits, from high impact resistance to resistance to cracks. The following are the advantages of using Lexan sheets for projects.

- Impact resistance that is 250 times higher than that of glass

- Resistant to cracks

- Highly resistant to diluted acids, gasoline, aliphatic hydrocarbons, and alcohols

- Can be cold-formed or bent

- Can be cut easily with a saw

- Provide 100% protection from harmful UV rays

- More flexible than acrylic and is available in different grades

- Highly transparent

7. What Are the Common Uses for Lexan Sheets?

Lexan is widely used in the following applications:

- Window covers

- Transparent visors for hockey and football helmets

- Bullet resistant glass

- LED light pipes and diffusers

- Reusable drinking bottles

- Phones and computers cases

- Machine guarding glass

- Greenhouses

Lexan Polycarbonate Sheet Suppliers in Toronto

Wondering where to get Lexan sheets? Canada Plastics & Belting Inc. is one of the biggest Lexan sheet suppliers in Toronto. We have years of experience in providing different grades of Lexan sheets and other plastics at affordable prices. Contact us today or request a quote for Lexan sheets for roofing and other applications.