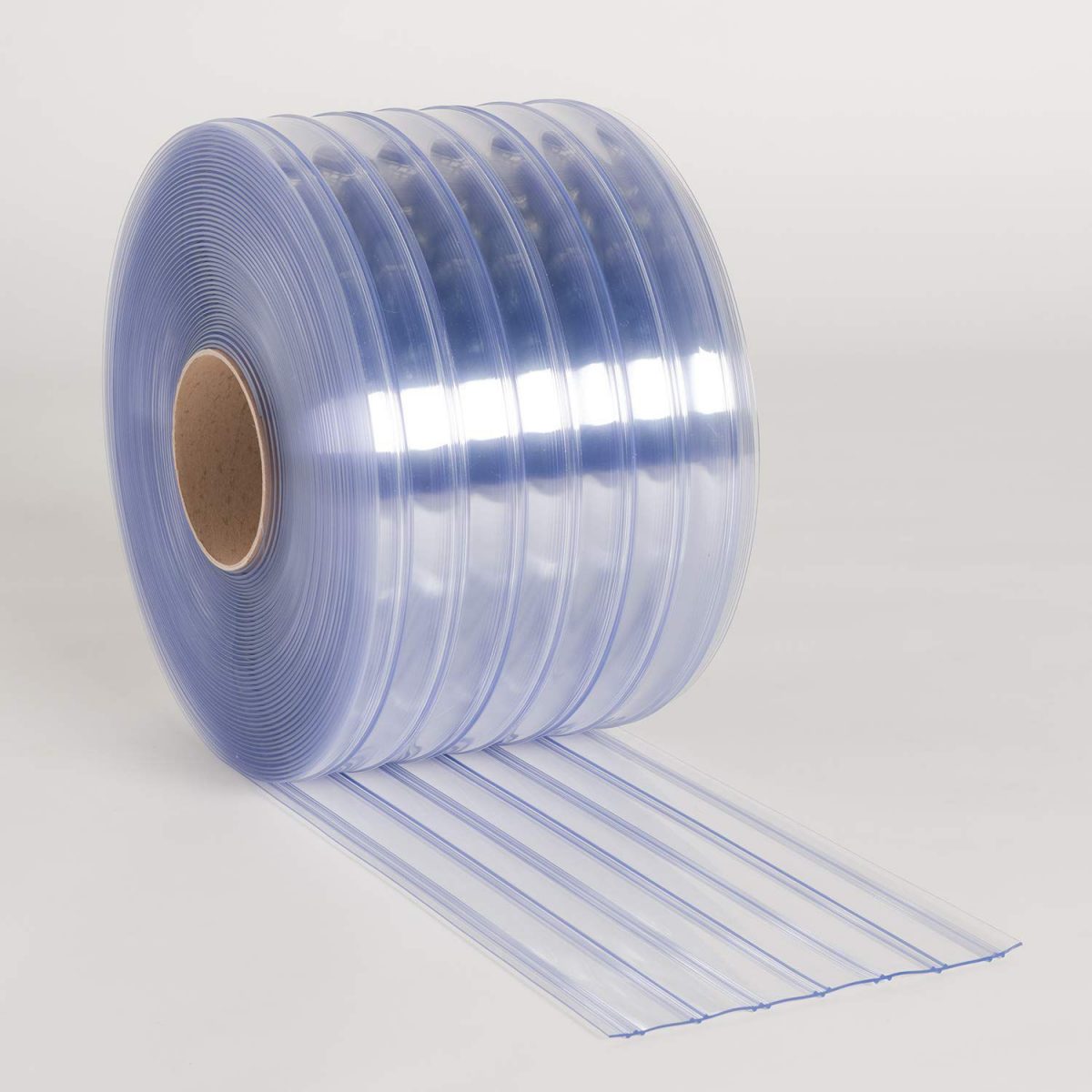

PVC curtains are increasingly becoming popular in food processing plants, and for the right reasons too.

Food processing plants lie at the heart of agricultural food processing, where raw crops become edible food items. As a highly industrialized setting, food processing plants have several advanced equipment and processing tools to ensure seamless processing operations and safety procedures while at it.

While the heavy machinery and processing tools are important features of these industrial plants, the physical condition of the establishment is just as important.

Food processing plants must have a mechanism for efficient temperature control. As food is produced, there’s always the risk of having unhealthy elements contaminating the finished product.

This is where PVC curtains for the food industry come in. Wondering how they can complement industrial operations? Here are some advantages:

Easily Divides Work Areas

PVC strip curtains are great for separating work areas, particularly in places that could otherwise result in food contamination. For instance, in food processing plants, they can keep out dust, noise, and toxic fumes. Such clear divisions of work areas also mean that workers know which places are off-bounds and can keep certain activities off these sensitive areas.

Regulates Temperatures Effectively

A key advantage of installing PVC curtains in a food processing plant is its efficient means of regulating temperatures. PVC curtains are made of special materials that prevent energy loss. Thus, food processing plants can retain the temperature levels required for optimum functionality.

Maintains High Hygiene Levels

Industrial work spaces like food processing plans are often areas where various substances permeate the air. A PVC curtain strip can help to cordon off certain areas, effectively serving as a contaminant and dust barrier. As such, areas with cleaner air, where food items are exposed, do not come in contact with these contaminants. This is an excellent workplace hygiene practice.

Protects from Welding Areas

PVC curtains for the food industry help to create bays or barriers to allow high-energy welding operations to take place while offering protection to those in the space against the harmful effects of UV. Overt exposure to UV can cause arc-eye. PVC curtain stripes are welding-grade and have the standard properties necessary to filter UV in the workspace.

Prevents Pest and Pollutant Infiltration

Many food manufacturers face issues involving external pollutants and pests infiltrating working areas. The presence of pollutants and pests is a huge risk to the quality of the food being produced. As such, installing PVC strip curtains can prohibit or reduce the incursion of insects and pests in the food processing plant, while fumes, dirt, and dust are equally kept out.

Contains Noise Cancellation Properties

Within the food processing plant, many operations occur, of which effective communication is key. Certain areas are perpetually noisy, with the sounds of grinding machinery often drowning out any attempt at meaningful verbal communication. It would be counterproductive to have the operators unable to communicate effectively in the plant due to unrestricted noise. A PVC strip curtain can help to separate these noisy areas from where other business dealings occur. Moreover, the material has noise-cancellation properties, so noise does not need to permeate the entire air.

Cost-Effective and Easy to Maintain

As a small food manufacturer, PVC curtains are a great and efficient, budget-friendly option that requires low maintenance. The plastic strips are highly durable and do not damage easily.

Withstands Extreme Temperatures

Because of the industrial activities that occur there, food processing plants often have extreme temperatures—either extreme heat or cold. PVC strip curtains are made of a synthetic plastic polymer that can survive extreme temperatures, making them highly durable.

Provides Better Accessibility and Transparency to the Plant

You’d be surprised to learn that PVC strip curtains can provide needed transparency and accessibility between various sections of the facility, despite its protective and insulating properties. Workers can easily move across various sections, as the material is light and simply hangs on entryways. Nevertheless, there’s no risk of mistaking it for anything else, as it’s quite clear. Also, the material makes it an excellent light reflector within the food processing plant.

Provides Two-Way Easy Access

Unlike regular doors that often open in one direction only, PVC strip curtains provide much-needed two-way access within the food processing plant. Anyone can enter into a space and easily leave in the same way, increasing accessibility to various sections within the plant.

Are you looking for the best PVC curtains solution for your food processing plant or company? Look no further than Canada Plastics and Belting Inc. to get your PVC curtains. Contact us today to learn more about choosing and installing the right PVC strip curtain for your business.

When it comes to walk-in freezers, cold storage, and other commercial food and restaurant areas,

When it comes to walk-in freezers, cold storage, and other commercial food and restaurant areas,

If you have worked or visited a factory recently you may remember some industrial barriers that were installed over there. These barriers are called

If you have worked or visited a factory recently you may remember some industrial barriers that were installed over there. These barriers are called

Plastic is a durable, light weight, cheap and easily modified material and has been extensively used in our daily lives.

Plastic is a durable, light weight, cheap and easily modified material and has been extensively used in our daily lives.