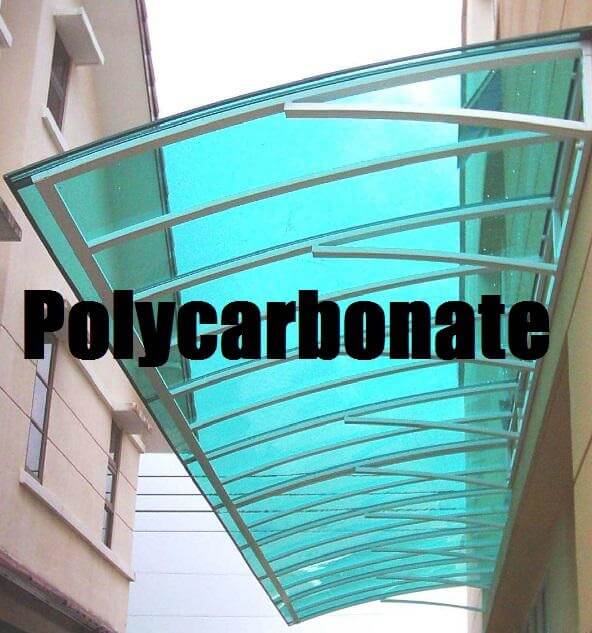

Polycarbonate is one of the most common building and roofing materials of choice in the construction industry. That’s because it has a lot going for it. In addition to being incredibly durable, flexible, lightweight, and versatile, polycarbonate is also scratch-resistant and fire-retardant. These are all important traits that make polycarbonate an ideal replacement for glass and other building materials traditionally used for decks and gazebos. Keep reading to learn about the different types of polycarbonate roofing panels that you should consider using for your new or existing outdoor structure.

Polycarbonate is one of the most common building and roofing materials of choice in the construction industry. That’s because it has a lot going for it. In addition to being incredibly durable, flexible, lightweight, and versatile, polycarbonate is also scratch-resistant and fire-retardant. These are all important traits that make polycarbonate an ideal replacement for glass and other building materials traditionally used for decks and gazebos. Keep reading to learn about the different types of polycarbonate roofing panels that you should consider using for your new or existing outdoor structure.

Solid Polycarbonates

Out of all of the varieties of polycarbonate sheets on this list, solid polycarbonates are the most visually plain, but they’re also extremely versatile and can be used for a wide range of applications. Solid polycarbonates come in a variety of colours that can be customized to match the aesthetic of your structure. They’re also available in different thickness levels ranging from 2 mm to 12 mm. Given their aesthetic and practical versatility, solid polycarbonate sheets are ideal for enclosing gazebos, decks, skylights, skywalks, stadium roofs, and other similar commercial or residential structures.

Embossed, Textured, Corrugated Polycarbonates

Embossed, textured, or corrugated polycarbonate sheets are similar in design and application to standard designs. The main difference is that these sheets have very pronounced ribbing that reinforces their durability and impact-resistance to withstand constant exposure to particularly harsh environmental elements. Ideal for greenhouses and gazebos, corrugated polycarbonate sheets transmit about 90% of sunlight and filter out harmful UV rays. Aside from these unique attributes, corrugated polycarbonate sheets are otherwise just as lightweight, flame-retardant, and immune to external damages as their counterparts.

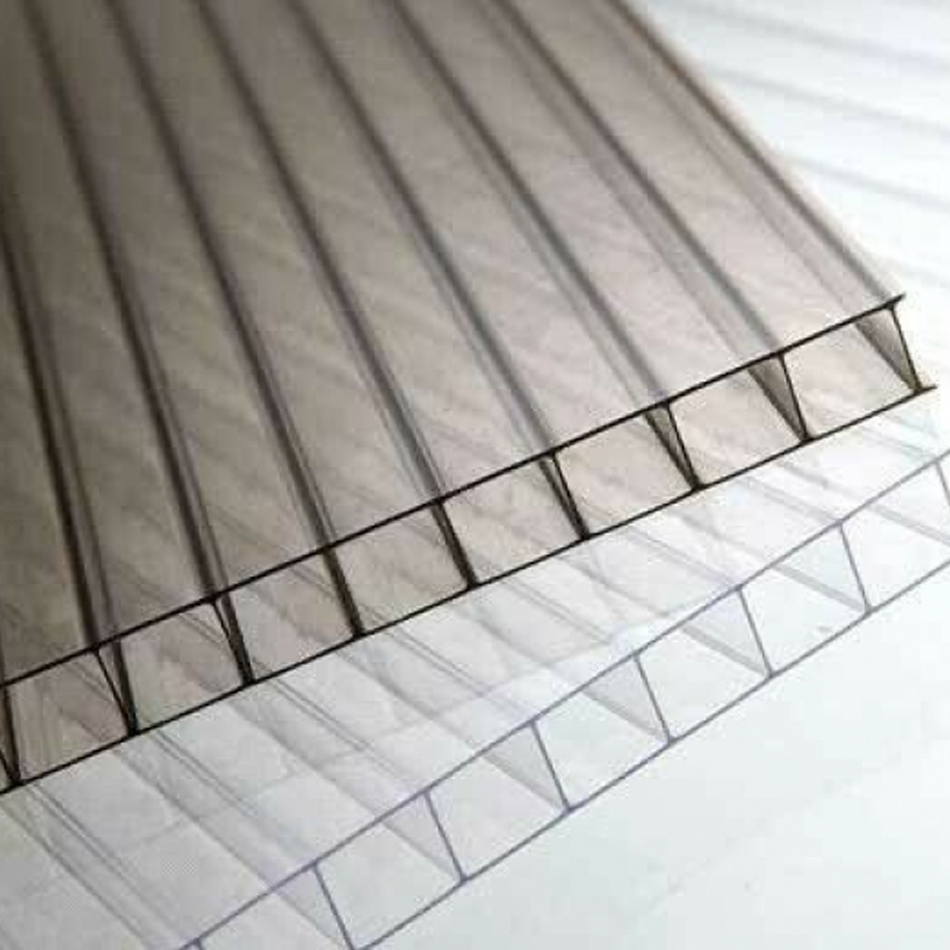

Twin-Wall Polycarbonate Sheets

Also known as multi-wall polycarbonate sheets, this design incorporates the use of multiple layers to further reinforce the strength, durability, stability, and impact resistance capacities of any structures to which they’re added. Multi-wall sheets typically consist of two smooth layers of solid polycarbonate on either side with one or more honeycomb-ribbed sheet sandwiched in between. Given their unparalleled strength, sturdiness, and uncanny resemblance to glass, most polycarbonate twin wall sheet suppliers typically recommend this design for outdoor residential and commercial structures such as decks, gazebos, ATMs, garages, parking structures, walkways, etc. Like their predecessors on this list, twin or multi-wall polycarbonate sheets are fully capable of providing extensive protection against external elements including UV rays, rain, snow, sleet, and any other harsh weather conditions.

They’re also available in a variety of colours, thicknesses, and transparencies according to the specific requirements of each building project.

Polycarbonate Sheet Suppliers in Toronto

You can end your search for “twin-wall sheet distributors” and “polycarbonate sheet suppliers near me” here. Canada Plastics & Belting Inc. is one of the foremost providers of top-quality polycarbonate sheets that are perfectly suited for a variety of construction projects in Toronto and the GTA. Whether you’re working on a residential DIY project or you need polycarbonate sheets for a large-scale construction development, we can provide you with the right product to suit your needs. Contact us today.

Polycarbonate is quickly becoming one of the most commonly used building materials in the professional and DIY construction industry. Even if you don’t know what polycarbonate is, the chances are very high that you’ve probably seen it used for a number of structures and construction projects over the past few years. Often used as a lightweight and more durable replacement for glass or standard plastic, polycarbonate has a lot of great qualities that make it a worthy contender for a substitute material for gazebo roof panels.

Polycarbonate is quickly becoming one of the most commonly used building materials in the professional and DIY construction industry. Even if you don’t know what polycarbonate is, the chances are very high that you’ve probably seen it used for a number of structures and construction projects over the past few years. Often used as a lightweight and more durable replacement for glass or standard plastic, polycarbonate has a lot of great qualities that make it a worthy contender for a substitute material for gazebo roof panels.

Over the past few years, polycarbonate has gradually become the go-to alternative building material to replace glass and acrylic for a number of reasons. It’s an extremely versatile material that boasts many different qualities that make it suitable for a variety of construction applications, including roofing. Constructed using thermoplastic polymer, polycarbonate roofing panels are completely transparent and durable, which makes them the ideal choice for greenhouses, skyscrapers, and automobiles. Keep reading to learn all about the benefits of polycarbonate gazebo roof panels for your next professional or DIY construction project.

Over the past few years, polycarbonate has gradually become the go-to alternative building material to replace glass and acrylic for a number of reasons. It’s an extremely versatile material that boasts many different qualities that make it suitable for a variety of construction applications, including roofing. Constructed using thermoplastic polymer, polycarbonate roofing panels are completely transparent and durable, which makes them the ideal choice for greenhouses, skyscrapers, and automobiles. Keep reading to learn all about the benefits of polycarbonate gazebo roof panels for your next professional or DIY construction project.

As far as roofing materials go, polycarbonate is arguably one of the most cost-effective, lightweight, affordable, and flexible choices available. It’s also more commonly used for roofing than most people think. People typically assume that all roofs are made up of clay, cement, asphalt, wood, or slate. Hardly anyone ever ventures to guess that a roof could consist of polycarbonate roofing panels.

As far as roofing materials go, polycarbonate is arguably one of the most cost-effective, lightweight, affordable, and flexible choices available. It’s also more commonly used for roofing than most people think. People typically assume that all roofs are made up of clay, cement, asphalt, wood, or slate. Hardly anyone ever ventures to guess that a roof could consist of polycarbonate roofing panels.

Twin-wall polycarbonate sheets, which are also known as multiwall sheets, are the ideal material choice for a variety of commercial construction and at-home DIY projects. They’re incredibly durable, yet lightweight, and they offer exceptional light transmission, which makes multiwall sheets great for greenhouses. Whether you’re running a professional operation or working on a personal project, working with the right polycarbonate sheet suppliers in Ontario makes a world of difference. Keep reading to learn more about the benefits of multiwall sheets for greenhouses and other applications.

Twin-wall polycarbonate sheets, which are also known as multiwall sheets, are the ideal material choice for a variety of commercial construction and at-home DIY projects. They’re incredibly durable, yet lightweight, and they offer exceptional light transmission, which makes multiwall sheets great for greenhouses. Whether you’re running a professional operation or working on a personal project, working with the right polycarbonate sheet suppliers in Ontario makes a world of difference. Keep reading to learn more about the benefits of multiwall sheets for greenhouses and other applications.