HDPE Sheets in Industrial Construction:

Durability and Sustainability

As the construction industry evolves, the demand for materials that offer both exceptional performance and environmental responsibility has never been greater. High-Density Polyethylene (HDPE) sheets have rapidly emerged as a preferred solution in modern industrial construction, celebrated for their outstanding durability, versatility, and eco-friendly profile. This article explores the pivotal role HDPE sheets play in today’s industrial projects, focusing on their durability, sustainability, and the broad range of applications that make them indispensable for builders and architects alike.

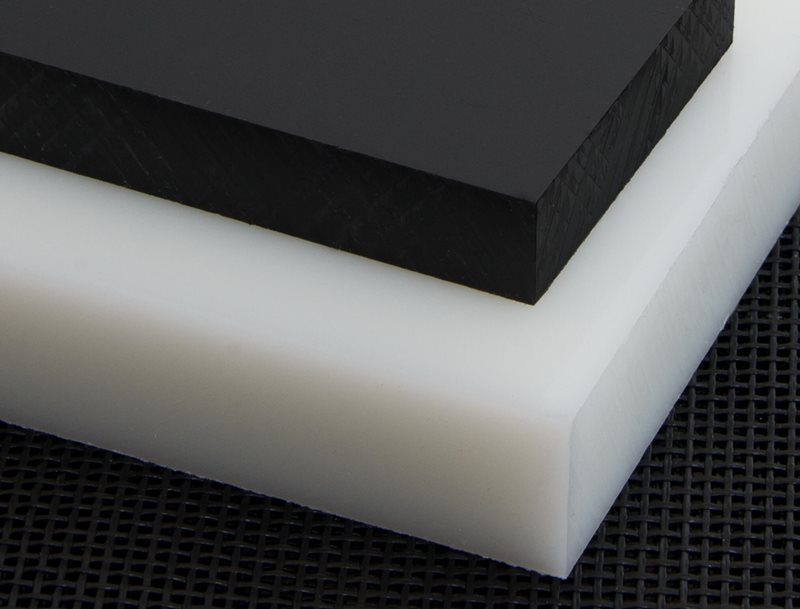

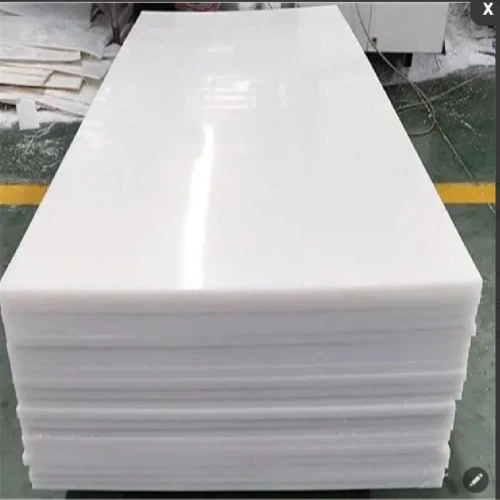

What Are HDPE Sheets?

HDPE sheets are flat panels manufactured from high-density polyethylene resin, a thermoplastic polymer known for its strength, chemical resistance, and adaptability. Available in a variety of thicknesses and sizes, HDPE sheets can be custom fabricated to meet the specific needs of diverse industrial construction projects. Their unique molecular structure gives them a high strength-to-weight ratio, making them both lightweight and exceptionally tough—qualities that are highly valued in demanding construction environments.

The Durability Advantage: Why HDPE Excels in Industrial Construction

- Exceptional Chemical Resistance

One of the defining features of HDPE sheets is their ability to withstand exposure to a wide range of chemicals, acids, and bases without degrading or corroding. In industrial settings—such as chemical processing plants, wastewater treatment facilities, and food processing environments—materials are often exposed to harsh substances that can rapidly deteriorate traditional construction materials. HDPE’s chemical resistance ensures long-term integrity and safety, reducing maintenance costs and the risk of structural failure over time.

- Low Moisture Absorption and Water Resistance

HDPE sheets are virtually impermeable to water and have an extremely low moisture absorption rate. This makes them an ideal choice for environments exposed to humidity, rain, or direct water contact. Unlike wood or certain metals, HDPE will not swell, warp, or rot, ensuring that structures remain stable and reliable even in wet or damp conditions. This property is especially valuable for outdoor applications, water containment systems, drainage solutions, and marine construction.

- High Impact Strength and Toughness

Industrial construction sites are subject to heavy mechanical stresses, impacts, and dynamic loads. HDPE sheets are engineered to absorb and dissipate impact energy, preventing cracking and breakage. This resilience is crucial for applications such as protective barriers, heavy-duty liners, and equipment guards, where safety and longevity are non-negotiable. The material’s toughness also contributes to safer work environments by reducing the risk of sudden material failure.

- Superior Weather and UV Resistance

HDPE’s resistance to UV radiation and extreme weather conditions means it retains its structural and aesthetic qualities over time, even when exposed to sunlight, temperature fluctuations, or harsh climates. UV-stabilized grades of HDPE further extend the lifespan of outdoor installations, reducing the need for frequent replacements and repairs.

- Lightweight and Easy to Fabricate

Despite its strength, HDPE is much lighter than traditional building materials like steel, concrete, or even some woods. This makes it easier to transport, handle, and install, reducing labor costs and speeding up project timelines. HDPE sheets can be easily cut, welded, bent, and shaped using conventional tools, allowing for custom solutions and rapid on-site adjustments.

Sustainability: HDPE’s Eco-Friendly Credentials

- Recyclability and Reuse

HDPE sheets are 100% recyclable, and the recycling process does not significantly degrade their quality. This means that offcuts, end-of-life panels, and manufacturing scraps can be collected, processed, and reformed into new sheets or other products, diverting plastic waste from landfills and supporting a circular economy. In fact, many modern HDPE sheets are produced using a blend of virgin and recycled material, further reducing environmental impact.

- Reduced Environmental Footprint

The production of HDPE is relatively energy-efficient compared to many traditional materials. When recycled HDPE is used, the energy and resources required are even lower, resulting in a smaller carbon footprint. By choosing HDPE, construction projects can significantly reduce their overall environmental impact, conserve natural resources, and help meet green building standards such as LEED or BREEAM.

- Long Service Life and Low Maintenance

The durability and weather resistance of HDPE mean that installations last longer and require less frequent replacement or repair. This longevity reduces the demand for raw materials and the energy associated with manufacturing and transporting new components, further enhancing the sustainability profile of HDPE-based construction.

- Supporting Green Building Certifications

Incorporating HDPE—especially recycled grades—into construction projects can contribute to earning points in green building certification systems. HDPE’s recyclability, low emissions, and potential for reuse align with the goals of sustainable construction and responsible material sourcing.

Applications of HDPE Sheets in Industrial Construction

The unique properties of HDPE sheets have led to their adoption across a wide spectrum of industrial construction applications:

- Chemical Storage and Processing Facilities: Used for tank linings, chemical-resistant walls, and secondary containment systems.

- Water and Wastewater Infrastructure: Ideal for pipelines, liners, baffles, and covers due to their impermeability and chemical resistance.

- Protective Barriers and Guards: Employed as impact-resistant panels, safety barriers, and machine guards in manufacturing plants.

- Vapor and Moisture Barriers: Used as underlayment, crawl space liners, and wall assemblies to prevent moisture intrusion and condensation.

- Outdoor Structures and Site Furnishings: From playground equipment and outdoor furniture to signage and landscaping features, HDPE’s weather resistance ensures long-lasting performance.

- Marine and Dock Construction: HDPE’s resistance to saltwater, UV, and impact makes it ideal for docks, piers, and marina infrastructure.

- Green Building Elements: Used in the construction of eco-friendly decking, fencing, green roofs, and rainwater harvesting systems.

- Temporary Construction Solutions: Lightweight HDPE sheets are perfect for temporary partitions, walkways, and protective surfaces on job sites.

Economic Benefits: Cost-Effectiveness and Efficiency

- Lower Material and Installation Costs

HDPE sheets are generally more affordable than many traditional construction materials. Their lightweight nature reduces shipping and handling expenses, while their ease of fabrication and installation translates into lower labor costs and faster project completion.

- Reduced Maintenance and Replacement

The inherent durability and resistance to environmental factors mean that HDPE installations require less maintenance and are less prone to damage or failure. This results in significant long-term savings, making HDPE a smart investment for industrial projects with tight budgets and demanding performance requirements.

- Versatility and Adaptability

HDPE sheets can be custom fabricated to meet the unique demands of each project, from complex shapes to precise dimensions. This flexibility streamlines construction processes, minimizes material waste, and allows for innovative design solutions that might not be possible with more rigid or brittle materials.

Innovation and Quality Assurance

Manufacturers of HDPE sheets adhere to rigorous quality standards, ensuring each sheet meets industry requirements for performance and safety. Innovations in HDPE technology—such as UV stabilization, antimicrobial treatments, and custom color or texture options—continue to expand the possibilities for industrial construction. Customization ensures that HDPE can be tailored for specific densities, applications, and environmental exposures, providing precision and reliability for every project.

Challenges and Considerations

While HDPE sheets offer a host of benefits, there are some considerations to keep in mind:

- Thermal Expansion: HDPE expands and contracts with temperature changes more than some other materials. Proper installation techniques and allowances are necessary to accommodate this movement.

- Mechanical Fastening: Special care must be taken when fastening HDPE, as overtightening can cause deformation or stress cracking.

- Surface Finish: Although HDPE is tough, it can scratch more easily than metals or harder plastics. Selecting the right finish or protective layer can help maintain appearance in high-traffic areas.

Despite these considerations, the advantages of HDPE far outweigh the challenges, especially when proper design and installation practices are followed.

Building a Sustainable Future with HDPE

The shift toward sustainable construction is not just a trend—it’s a necessity. HDPE sheets embody the principles of modern, responsible building: durability, versatility, and a commitment to minimizing environmental impact. By choosing HDPE, industrial builders and designers are investing in materials that perform exceptionally well under pressure, support circular economy practices, and help create safer, longer-lasting, and more sustainable structures.

From chemical plants and water treatment facilities to outdoor infrastructure and green building projects, HDPE sheets are setting new standards for what’s possible in industrial construction. As technology advances and recycling practices become even more efficient, HDPE’s role in shaping a greener, more resilient built environment will only grow.

Ready to Build Smarter?

If you’re planning an industrial project and want to maximize durability, efficiency, and sustainability, consider integrating HDPE sheets into your design.

For high-quality, eco-friendly HDPE sheets and expert guidance, explore the range at Canada Plastics & Belting Inc.. Build for today – and for the future – with HDPE.