When planning your next outdoor construction project, selecting the right roofing material can make all the difference. UV-coated polycarbonate corrugated sheets have emerged as a leading choice for Canadian homeowners and builders who demand both performance and longevity. These innovative panels combine exceptional durability with superior UV protection, making them ideal for everything from greenhouse construction to patio covers.

The Harmful Effects of UV Radiation on Humans and Materials

Understanding the impact of ultraviolet radiation helps explain why UV protection is so crucial in building materials. Health Canada identifies UV radiation as invisible energy that affects our health in different ways depending on its wavelength and intensity.

- UVA radiation (320-400nm) penetrates deep into skin and can cause immediate tanning, premature aging, and contribute to certain skin cancers. While about 95% of UVA reaches Earth’s surface, it’s less energetic than UVB radiation.

- UVB radiation (280-320nm) is more energetic and responsible for sunburns and most skin cancers. Fortunately, the ozone layer absorbs much of this radiation, with only about 5% reaching our planet’s surface.

Beyond human health concerns, UV radiation wreaks havoc on building materials. Prolonged exposure causes:

- Fading and discolouration of surfaces

- Material brittleness that leads to cracking

- Structural degradation that compromises integrity

- Surface chalking and deterioration

Research shows that UV-induced photo-oxidation reactions in plastics result in surface discolouration and cracking, accompanied by loss of mechanical integrity over time. Without proper protection, even high-quality materials can fail prematurely under Canada’s varying UV conditions.

The Role of UV Protection in Modern Construction

UV-resistance has become a critical factor when choosing outdoor roofing materials for Canadian construction projects. Our climate presents unique challenges, with UV intensity varying significantly by season, altitude, and surface reflection—especially from snow, which can reflect up to 85% of UV radiation.

Critical applications where UV protection is essential include:

- Skylights and transparent roofing

- Greenhouse glazing

- Outdoor recreational structures

- Commercial building facades

- Residential carports and pergolas

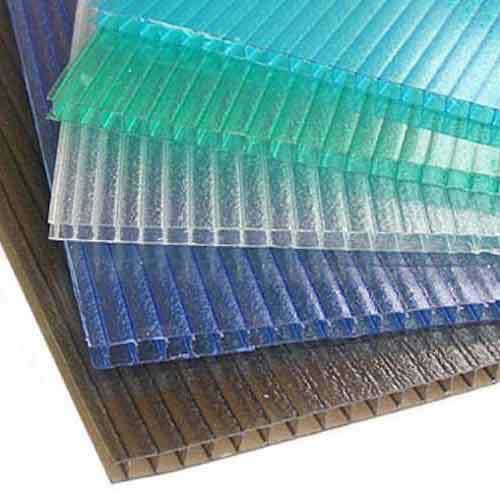

Why UV-Coated Polycarbonate Corrugated Sheets Are Ideal for Roofing

UV-coated polycarbonate corrugated sheets outperform traditional materials like PVC and metal in several key areas. Below are some of the benefits of UV-coated polycarbonate sheets:

Superior Light Transmission with UV Filtering

One of polycarbonate’s most valuable features is its ability to allow up to 85% natural light transmission while blocking harmful UV rays. This creates an ideal balance where you receive:

- Abundant natural lighting that reduces electricity costs

- Reduced glare for comfortable indoor environments

- Minimal heat buildup that prevents overheating

- Complete UV protection for both occupants and interior furnishings

This makes UV-coated polycarbonate perfect for applications requiring daylight without UV exposure risks.

Resistance to Yellowing, Cracking, and Heat Distortion

The UV coating prevents the most common forms of material degradation:

- Anti-yellowing protection maintains a crystal-clear appearance

- Crack resistance ensures long-term structural integrity

- Heat distortion prevention maintains shape even in extreme temperatures

- Chemical stability resists environmental pollutants

Quality UV-coated polycarbonate maintains its original properties for decades, with many manufacturers offering 10-year warranties against yellowing and significant light transmission loss.

Applications for UV-Coated Corrugated Sheets

- Pergolas: Create comfortable outdoor living spaces with filtered natural light and complete weather protection.

- Carports: Protect vehicles from UV damage, hail, and weather while maintaining visibility and reducing the feeling of being enclosed.

- Patios: Extend outdoor entertaining seasons with polycarbonate corrugated roofing panels that don’t block natural light.

- Greenhouses: Provide optimal growing conditions with high light transmission, UV plant protection, and excellent insulation properties.

- Covered Walkways: Ensure safe, well-lit passages between buildings while protecting from elements.

- Outdoor Gazebos: Create year-round rooms that resist fading and maintain structural integrity with corrugated polycarbonate panels for outdoor spaces.

Make the Smart Choice for Your Project with Canada Plastics and Belting Inc.

UV-coated polycarbonate corrugated sheets represent the perfect marriage of functionality and durability for Canadian construction projects. They offer superior protection against our harsh UV conditions while delivering the light transmission, impact resistance, and thermal performance that traditional materials simply cannot match.

Whether you need polycarbonate corrugate sheets for your greenhouse, are creating a carport to protect your vehicles, or designing an outdoor living space, UV-coated polycarbonate provides unmatched value through reduced maintenance, enhanced longevity, and consistent performance year after year.

Ready to experience the difference quality makes? Explore Canada Plastics and Belting Inc.’s comprehensive collection of UV-coated polycarbonate solutions and discover why more Canadian builders are making the switch to this revolutionary material. Contact us today to explore your options.