Top 5 Interior Trends Featuring ACP Wall Panels in 2025

Interior design is always evolving, but 2025 is shaping up to be a year where innovation, sustainability, and bold aesthetics take center stage. At the heart of this transformation are Aluminum Composite Panels (ACP), which are quickly becoming the go-to material for designers and architects seeking both style and function. From residential spaces to commercial environments, ACP wall panels are redefining what’s possible in interior design.

So, what makes ACP wall panels so special? Their unique blend of durability, versatility, and modern appeal allows them to seamlessly adapt to a wide range of design trends. Here are the top five interior trends for 2025 that showcase how ACP wall panels are leading the way in contemporary design.

1.) Textured and 3D ACP Wall Panels: Adding Depth and Dimension

Flat, featureless walls are a thing of the past. In 2025, designers are embracing textured and 3D ACP wall panels to create immersive, tactile environments. These panels go beyond simple color and finish, introducing depth and movement to any space.

Why is this trend so popular?

- Visual Interest: 3D ACP panels can mimic natural materials like stone, wood, or even sculptural forms, turning a plain wall into a work of art.

- Versatility: Whether you want subtle fluting, bold geometric patterns, or organic waves, ACP panels can be customized to fit your vision.

- Light Play: The dimensional surfaces interact with natural and artificial light, creating dynamic shadows and highlights throughout the day.

Where to use:

Textured ACP panels are perfect for accent walls in living rooms, hotel lobbies, office reception areas, and even retail spaces where first impressions matter.

At Canada Plastics & Belting, we offer a wide range of ACP panels with customizable textures and finishes, allowing you to bring this trend to life in any setting.

2.) Sustainability and Eco-Friendly Design

As environmental awareness grows, sustainability is no longer just a buzzword-it’s a necessity. In 2025, eco-friendly interiors are in high demand, and ACP wall panels are helping designers meet these expectations.

How are ACP panels sustainable?

- Recycled Content: Many ACP panels are made with recycled aluminum and eco-friendly cores, reducing their environmental impact.

- Energy Efficiency: ACP panels can reflect heat and light, helping to regulate indoor temperatures and lower energy consumption.

- Longevity: Their durability means less frequent replacements, reducing waste over time.

Designers are choosing ACP panels for:

- LEED-certified projects

- Green office renovations

- Eco-conscious residential builds

For more on sustainable building materials, check out this U.S. Green Building Council resource.

At Canada Plastics & Belting, we’re committed to providing ACP solutions that support greener, healthier interiors.

3.) Metallic Accents and Luxe Finishes

Luxury is making a comeback in 2025, but with a modern twist. Metallic ACP wall panels-in gold, bronze, copper, and brushed aluminum-are the ultimate way to add a touch of glamour and sophistication to any space.

Why metallics?

- Reflective Qualities: Metallic finishes bounce light around the room, making spaces feel larger and more open.

- Timeless Appeal: Metals never go out of style and can be paired with both classic and contemporary décor.

- Durability: ACP’s scratch-resistant surfaces ensure that your luxe look lasts for years.

Where to use:

- Feature walls in living rooms or bedrooms

- Restaurant and hotel interiors

- Office boardrooms and executive suites

Pair metallic ACP panels with neutral tones for a “quiet luxury” effect, or go bold by mixing metals for a more eclectic vibe. As highlighted by ELLE Decor, metallics are a cornerstone of the “new luxury” trend, blending opulence with practicality.

4.) Bold Colors and Custom Graphics

2025 is all about self-expression. Homeowners and businesses alike are moving away from safe, neutral palettes and embracing bold colors and custom graphics on their ACP wall panels.

What’s driving this trend?

- Personalization: Custom-printed ACP panels can display anything from abstract art to branded graphics, making each space unique.

- Vibrant Hues: Rich blues, emerald greens, and energetic reds are taking over, especially in creative workspaces and hospitality settings.

- Color Psychology: Designers are using color to influence mood-think calming greens in wellness centers or energizing oranges in collaborative offices.

Advantages of ACP panels for color and graphics:

- Advanced coatings keep colors vivid and fade-resistant, even in direct sunlight.

- Seamless installation allows for large, uninterrupted graphic displays.

- Easy to clean and maintain, making them ideal for high-traffic areas.

Whether you want to make a statement or reinforce your brand, ACP wall panels offer endless possibilities for creative expression.

5.) Indoor-Outdoor Integration

One of the most exciting trends for 2025 is the blurring of boundaries between indoor and outdoor spaces. Homeowners and designers are seeking harmony with nature, and ACP wall panels are the perfect material to achieve this seamless transition.

Why ACP panels excel here:

- Weather Resistance: ACP panels withstand humidity, UV rays, and temperature fluctuations, making them ideal for both interiors and sheltered exteriors.

- Natural Finishes: Wood-look and stone-look ACP panels create visual continuity between garden-facing rooms and outdoor patios.

- Low Maintenance: Unlike real wood or stone, ACP panels require minimal upkeep and retain their beauty year-round.

Applications:

- Sunrooms and covered patios

- Pool houses and cabanas

- Open-plan living areas with retractable doors

Pair ACP wall panels with large windows, sliding glass doors, and lush indoor plants for a true biophilic design that brings the outdoors in.

Why ACP Wall Panels Are the Future of Interior Design

Beyond these trends, there are several reasons why ACP wall panels are becoming the preferred choice for designers and property owners:

Versatility

ACP panels can be cut, shaped, and finished in countless ways, making them suitable for virtually any design vision-from minimalist to maximalist.

Durability

Resistant to moisture, impact, and fading, ACP panels are built to last. This makes them a smart investment for both residential and commercial projects.

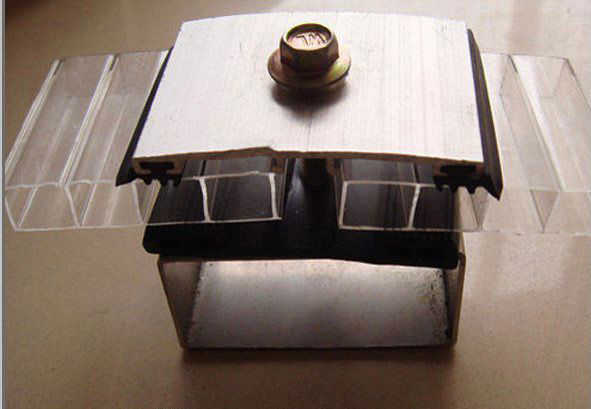

Easy Installation

Lightweight and easy to handle, ACP panels can be installed quickly, reducing labor costs and project timelines.

Low Maintenance

Unlike traditional materials that require regular painting, sealing, or repairs, ACP panels retain their appearance with simple cleaning.

Cost-Effectiveness

While offering a high-end look, ACP panels are often more affordable than natural materials, especially when considering their longevity and low upkeep.

How to Incorporate ACP Wall Panels Into Your Next Project

Ready to embrace these 2025 trends? Here are some tips for integrating ACP wall panels into your space:

- Start with a Statement Wall: Choose a bold color, texture, or metallic finish for a single accent wall to instantly update your space.

- Mix and Match: Combine different ACP finishes-such as matte and gloss, or wood and metal-for a layered, designer look.

- Think Beyond Walls: ACP panels can also be used for ceilings, cabinetry, and even furniture fronts for a cohesive design.

- Consult the Experts: Work with experienced suppliers like Canada Plastics & Belting to ensure you select the right panel type, finish, and installation method for your needs.

Conclusion

As we move into 2025, ACP wall panels are at the forefront of interior design innovation. Their unmatched versatility, sustainability, and aesthetic range make them the ideal choice for anyone looking to create modern, functional, and beautiful spaces. Whether you’re drawn to textured 3D surfaces, eco-friendly materials, luxe metallics, bold colors, or seamless indoor-outdoor living, ACP panels offer the perfect solution.

At Canada Plastics & Belting, we’re proud to offer a comprehensive selection of ACP wall panels that meet the demands of today’s designers and tomorrow’s trends. Explore our range and let your creativity take flight!