Truck beds are designed to handle a variety of tasks, from hauling construction materials to carrying camping gear. This multi-purpose nature exposes the bed to constant wear and tear, including common threats like scratches, dents, and corrosion.

Truck beds are designed to handle a variety of tasks, from hauling construction materials to carrying camping gear. This multi-purpose nature exposes the bed to constant wear and tear, including common threats like scratches, dents, and corrosion.

High-density polyethylene (HDPE) truck bed liners offer excellent protection, preserving your truck bed’s condition and extending its lifespan. This blog post explores the benefits and how these HDPE sheets keep your truck bed pristine.

How HDPE Truck Bed Liners Prevent Truck Beds from Scratches, Dents, and Corrosion

Understanding the characteristics of HDPE sheets is key to appreciating how HDPE truck bed liners effectively prevent damage.

Protection from Scratches

HDPE sheets for truck bed liners act as a barrier between your truck bed and potential sources of scratches. The durable material absorbs the impact of sharp tools, cargo, and debris, preventing them from reaching the bed’s surface. Common causes of scratches, such as moving heavy equipment or transporting sharp objects, are effectively mitigated with HDPE liners.

Defense against Dents

The impact resistance of HDPE material makes it an excellent choice for preventing dents. Whether you’re loading heavy construction materials or accidentally dropping tools, HDPE truck bed liners absorb the impact, protecting the underlying metal bed. This ensures that your truck bed remains dent-free, maintaining its structural integrity.

Corrosion Prevention

One of the most significant advantages of HDPE truck bed liners is their resistance to water, chemicals, and rust. The non-porous nature of HDPE prevents moisture from seeping into the truck bed, reducing the risk of corrosion. By keeping water and chemicals at bay, HDPE liners contribute to the longevity of your truck bed, ensuring it remains rust-free for years to come.

Long-Term Benefits of HDPE Truck Bed Liners

Extended Truck Bed Longevity

HDPE truck bed liners act as a protective shield, minimizing wear and tear on the underlying metal bed. This barrier prevents rust and extends the lifespan of the truck bed, allowing you to enjoy your vehicle for longer without worrying about costly repairs.

Preserved Resale Value

A well-protected truck bed retains its resale value much better than a damaged or worn-out bed. When it comes time to sell your truck, potential buyers will appreciate the pristine condition of the bed, leading to a higher resale price. HDPE liners ensure that your truck remains in top condition, maximizing its value.

Practical Tips for Using HDPE Truck Bed Liners

To get the most out of your HDPE truck bed liners, follow these practical tips:

- Clean and dry the truck bed thoroughly: This prevents moisture and corrosion from building up under the liner.

- Consider adhesive or double-sided tape: For added security, use adhesive or tape to keep the liner in place.

- Leave a small gap: Allow around 1/4 inch for expansion and contraction, ensuring a snug fit.

- Clean periodically: Use mild soap and water to clean the liner and maintain its appearance.

- Inspect for wear or damage: Regularly check for any signs of wear or damage and tighten loose fasteners.

- Distribute loads evenly: Prevent excessive wear by evenly distributing the load in the truck bed.

- Avoid dragging heavy or sharp objects: Minimize scratches by lifting and placing objects instead of dragging them.

- Avoid sudden impacts in cold climates: HDPE can become brittle in cold temperatures, so handle heavy objects with care.

- Seal cut edges: Use plastic trim to seal cut edges and prevent moisture intrusion.

Choose Canada Plastics’ HDPE Sheets for Truck Bed Liners

Protecting your truck bed with custom HDPE sheets is a cost-effective solution that offers numerous benefits. By investing in HDPE liners, you can extend the lifespan of your truck bed, preserve its resale value, and enjoy the peace of mind that comes with knowing your vehicle is well-protected.

Contact Canada Plastics and Belting Inc., a leading HDPE sheets supplier in Toronto, for top-quality HDPE truck bed liners and start safeguarding your truck today.

Fiber-reinforced plastic (FRP) sheets are making waves in the design world. Known for their durability and versatility, these sheets are increasingly being used in contemporary spaces. But it’s the aesthetic potential of white FRP sheets that truly sets them apart. With their sleekness, reflective properties, and ease of maintenance, they are a dream material for anyone looking to modernize their space.

Fiber-reinforced plastic (FRP) sheets are making waves in the design world. Known for their durability and versatility, these sheets are increasingly being used in contemporary spaces. But it’s the aesthetic potential of white FRP sheets that truly sets them apart. With their sleekness, reflective properties, and ease of maintenance, they are a dream material for anyone looking to modernize their space.

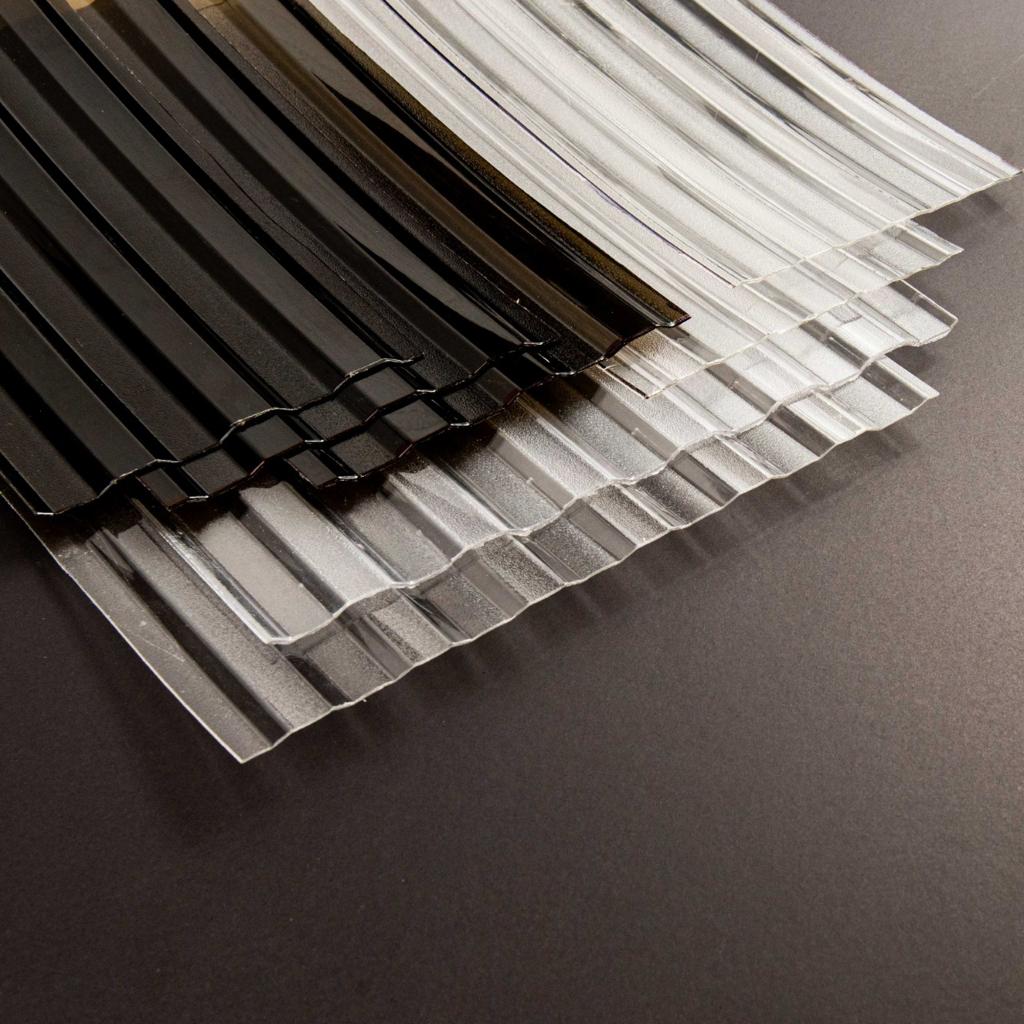

In the quest for sustainable living, homeowners are increasingly turning to green solutions that don’t compromise on style or functionality. Polycarbonate awnings, a modern alternative to traditional materials, are gaining popularity due to their eco-friendly properties and impressive durability. Whether you’re looking to reduce your energy bills, protect your interiors, or simply add a sophisticated touch to your home, polycarbonate awnings are an excellent choice. Canada Plastics & Belting Inc. offers top-tier sustainable awnings, perfectly suited for homeowners in Toronto who are committed to going green.

In the quest for sustainable living, homeowners are increasingly turning to green solutions that don’t compromise on style or functionality. Polycarbonate awnings, a modern alternative to traditional materials, are gaining popularity due to their eco-friendly properties and impressive durability. Whether you’re looking to reduce your energy bills, protect your interiors, or simply add a sophisticated touch to your home, polycarbonate awnings are an excellent choice. Canada Plastics & Belting Inc. offers top-tier sustainable awnings, perfectly suited for homeowners in Toronto who are committed to going green.