Have you ever wondered why certain materials seem to balance strength, flexibility, and affordability so well? From a durable outdoor sign to a reusable packaging solution and even roofing material, innovative materials are transforming entire industries quietly. Coroplast sheets lead the revolution with unique properties and versatility.

Understanding Coroplast Sheets

These coroplast sheets are corrugated plastic sheets produced with polypropylene copolymer. They have lightness, are durable, and provide the best economical alternatives to numerous applications.

These sheets resist moisture, chemicals, and UV rays to guarantee durability in any indoor or outdoor setting. There are coroplast sheets available in several sizes, colors, and thicknesses, thus being ideal for industries looking for function but with customization.

Applications Across Industries of Coroplast Sheets

- Advertising and Marketing

Coroplast sheets are popularly used for temporary signage and promotional displays, with features like weather resistance and vibrant printability.

- Packaging and Shipping

Their rigid but lightweight construction makes coroplast sheets ideal for reusable packaging for the protection of goods during shipment.

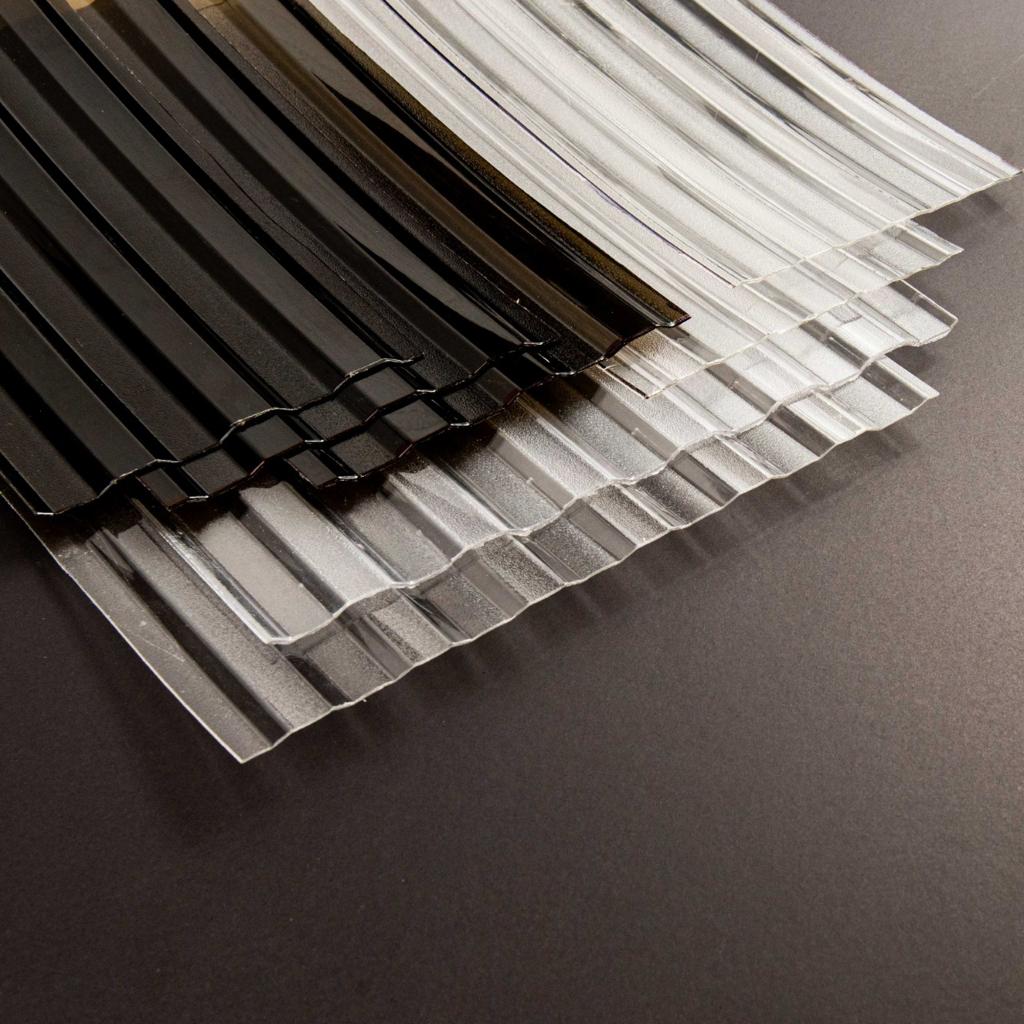

- Roofing Solutions

Coroplast sheets, when used with polycarbonate roof panels, add durability and cost-effectiveness to any roofing project.

- Creative Projects

From DIY organizers to artistic designs, coroplast sheets not only empower creators but also provide a versatile medium to bring their ideas to life. Furthermore, these sheets are lightweight, durable, and easy to work with, making them ideal for both beginners and experienced crafters. Therefore, whether you’re crafting for personal use or professional projects, coroplast sheets offer endless possibilities to unleash your creativity.

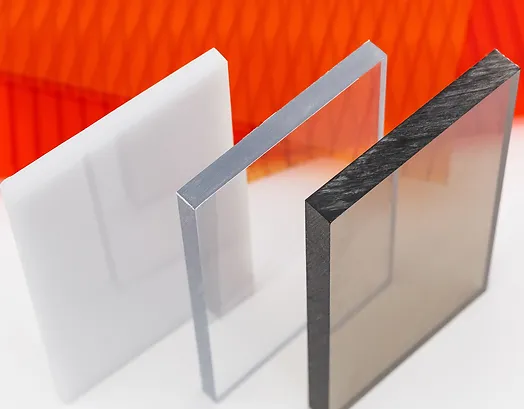

3 Types of Coroplast Sheets

- Standard Coroplast Sheets

Standard coroplast sheets are versatile, lightweight, and affordable. They are used in temporary signage, school projects, and crafting because they are easy to customize and durable.They are ideal for DIY enthusiasts and businesses alike and are a practical choice for creating impactful, low-cost solutions.

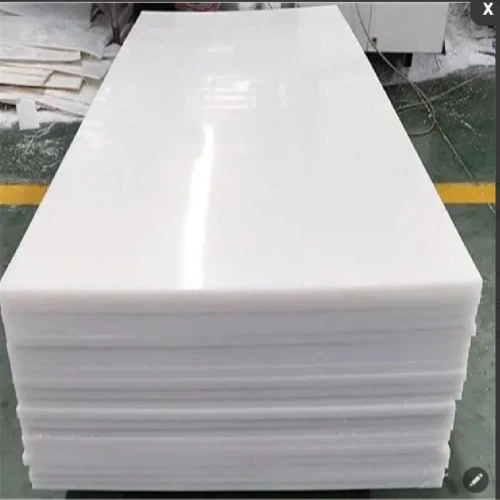

- White Acrylic Coroplast Sheets

White acrylic sheets are highly valued for their smooth, clean surface, which provides a professional finish. Such sheets are ideal for advertising and retail industries that require high-quality visuals. Such sheets offer excellent printability for sharp graphics and clear text, making them ideal for use in promotional stands, point-of-purchase displays, and indoor or outdoor advertisements. Their light but sturdy nature does guarantee they can be light enough to move around and installed in places for perfect branding and display purposes.

- Black Coroplast Sheets

Black Coroplast sheets are also durable and have an industrial look for aesthetic application purposes. Coroplast sheets are often used in construction for floor covers or temporary barrier purposes. They are resistant to water, chemicals, and UV radiation, giving them an exceptionally long period of operation within demanding situations. In signage applications, black Coroplast sheets can be commonly used since their modernized, polished finish disguises grime and abrasions making them well-suited for upscale displays and business identities.

Canada Plastics: Your Partner for High-Quality Plastic Solutions

Canada Plastics is a premier brand in high-quality materials such as coroplast sheets, white acrylic sheets, and polycarbonate roof panels. They offer a wide range of items in their catalog, targeting different sectors like advertising, construction, packaging, and creative DIY projects. Focusing more on durability and reliability, the materials from Canada Plastics meet high standards, making them one of the most trusted brands by professionals and hobbyists alike.

What makes Canada Plastics different is its commitment to satisfaction for customers through personalized solutions. They offer customization, professional advice, and shipping to every corner of the nation to ensure clients find their desired materials for their projects. Be it designing professional signages, constructing sturdy roofs through polycarbonate panels, or coming up with unique packaging solutions, Canada Plastics can do it all—bringing quality, expertise, and convenience to every project.

FAQS

- What are Coroplast sheets used for?

Coroplast sheets are utilized for temporary signage, packaging, construction, advertising, and DIY projects due to their lightweight and durable properties.

- Where can I get the best Coroplast Sheets?

You can get high-quality coroplast sheets, black and white, from Canada Plastics. They offer customization services and reliable shipping across Canada.

Conclusion

Coroplast sheets are versatile and durable enough for industries and DIYers alike. With the adaptability, combined with Canada Plastics‘ high-quality options and excellent service, they are a perfect material for many applications. Explore the possibilities today and take your projects to the next level.