Aluminum composite panels (ACP) are made from a versatile material that can be used for a variety of applications. They are made up of two sheets of aluminum that are thermally bonded to a core material, usually polyethylene. This combination creates a panel that is lightweight, yet strong and durable. Aluminum composite panels can be used for both interior and exterior applications, making them the perfect solution for many projects!

Aluminum composite panels (ACP) are made from a versatile material that can be used for a variety of applications. They are made up of two sheets of aluminum that are thermally bonded to a core material, usually polyethylene. This combination creates a panel that is lightweight, yet strong and durable. Aluminum composite panels can be used for both interior and exterior applications, making them the perfect solution for many projects!

In this blog post, we explore the various applications of ACP in detail.

Interior Applications of Aluminum Composite Panels

Interior aluminum composite panels can be used for a variety of applications, such as wall cladding, ceiling panels, partitions, and more. Aluminum composite panels are a great choice for interior applications because they are easy to clean and maintain.

- Walls: Aluminum composite panels can be used to create beautiful, modern accent walls. They are lightweight and easy to install, making them a great option for DIY projects.

- False Ceilings: ACP can be used to create a variety of ceiling designs. False ceilings not only make the appearance of interiors more attractive, but they also aid in temperature regulation. Aluminum composite panels are perfect for this application since they are made of a polyethylene core that serves as a heat-proofing agent for temperature control.

- Partitions: Aluminum composite panels can be used to create stylish partitions. They are light and easy to handle, making them a great option for office spaces or home renovations.

- Sound Barriers: Since ACP are double layered, they can also be used as a sound barrier. Aluminum composite panels absorb sound and prevent sounds from travelling in indoor spaces like offices.

- Column Covers: Aluminum composite panels can be used to cover columns. They are fire resistant and have a high resistance to impact, making them a great option for both commercial and residential applications.

- Elevator Cabs: Lastly, aluminum composite panels can be used to create stylish elevator cabs. Since they are easy to install and maintain, they are a great option for high-rise buildings.

Exterior Applications of Aluminum Composite Panels

Exterior aluminum composite panels are the perfect solution for cladding, facades, and signage applications. ACP are resistant to weathering and fading and are available in a variety of colours and finishes. Aluminum composite panels allow you to create the perfect look for your project which is why they are an ideal choice for exterior applications.

- Cladding: Aluminum composite panels can be used for cladding. Due to the fact that they are lightweight, they are a great option for both new construction and renovation projects. Aluminum composite panels can endure a considerable amount of strain and, as a result, modern-day buildings are clad with it.

- Roof Edges: Aluminum composite panels can also be used for fascias and roof edges. Since ACP are resistant to weathering, it makes them particularly ideal for extending the lifespan of buildings and façades for both commercial and residential applications. In addition, they are easy to install and maintain.

- Curtain Walls and Parapet Walls: Due to their double-layer design, aluminum composite panels can be used to create curtain walls and parapet walls, which is why the are often used in both new construction and renovation projects.

- Signage: Lastly, outdoor signs and hoardings must endure temperature swings, winds, and exposure to rain and snow. Because of this, they must be made using a material that can weather the elements. Aluminum composite panels are ideal for outdoor signage because they are weather-resistant and light in weight.

Contact Canada Plastics & Belting for Aluminum Composite Panels in Toronto

Aluminum composite panels are the perfect solution for your next project! If you’re looking for ACP in Toronto, look no further than Canada Plastics & Belting Inc. We are proud to offer a wide selection of aluminum composite panels in multiple colours, sizes, and thickness options.

We’re a leading stockist and supplier of aluminum composite panels, acrylic sheets, plexiglass sheets, polycarbonate solid sheets, polycarbonate corrugated twin wall sheets, polycarbonate roofing panels, and more. Contact us today for all your aluminum composite panel needs or call us at 416-291-3036 for a free quote.

Are you looking for a versatile and strong building material? If so, then aluminium composite panels may be the perfect choice for you.

Are you looking for a versatile and strong building material? If so, then aluminium composite panels may be the perfect choice for you.

Awnings have been used for centuries to provide shade and shelter from the elements. Awnings are a great way to improve the look of your home, and they can also provide some protection from the rain and sun.

Awnings have been used for centuries to provide shade and shelter from the elements. Awnings are a great way to improve the look of your home, and they can also provide some protection from the rain and sun.

Acrylic sheets are one of the more versatile and enduring materials used across the globe in numerous industries and are now becoming people’s favorite especially black acrylic sheets. In all likelihood, it is possible that you have a lot of products in your home which are made up of acrylic, if not literally, most parts of your home are possibly constructed from some kinds of acrylic. Over the conventional glass used in homes, acrylic plastic offers many more advantages and offers a flexible approach to product design for many companies. The attractiveness that it brings to the whole space is just the perfect icing on the cake.

Acrylic sheets are one of the more versatile and enduring materials used across the globe in numerous industries and are now becoming people’s favorite especially black acrylic sheets. In all likelihood, it is possible that you have a lot of products in your home which are made up of acrylic, if not literally, most parts of your home are possibly constructed from some kinds of acrylic. Over the conventional glass used in homes, acrylic plastic offers many more advantages and offers a flexible approach to product design for many companies. The attractiveness that it brings to the whole space is just the perfect icing on the cake.

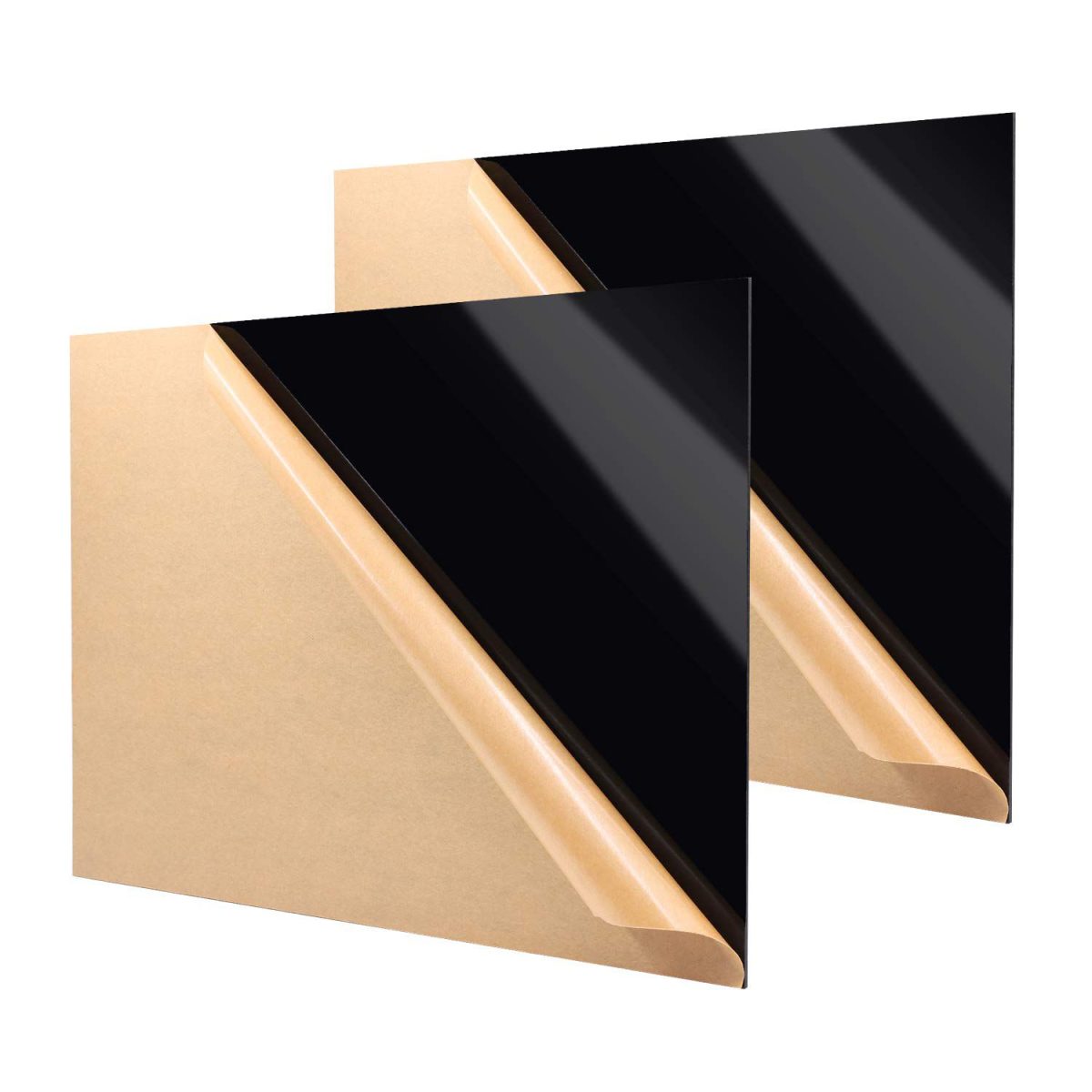

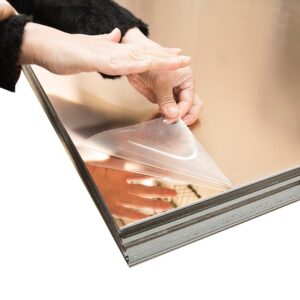

An acrylic mirror sheet is a piece of plastic that has been treated to have the same reflective properties as a traditional glass mirror. The surface of the sheet consists of thousands of tiny, mirrored facets, which give it its highly reflective appearance.

An acrylic mirror sheet is a piece of plastic that has been treated to have the same reflective properties as a traditional glass mirror. The surface of the sheet consists of thousands of tiny, mirrored facets, which give it its highly reflective appearance.

Made of polymethyl methacrylate (PMMA), also known as acrylic, acrylic mirror sheets have many uses in a wide range of industries. This type of plastic is highly durable and offers excellent resistance to weathering, moisture, heat, and UV radiation. In addition, acrylic mirror sheets are lightweight and easy to work with, making them ideal for a variety of applications.

Made of polymethyl methacrylate (PMMA), also known as acrylic, acrylic mirror sheets have many uses in a wide range of industries. This type of plastic is highly durable and offers excellent resistance to weathering, moisture, heat, and UV radiation. In addition, acrylic mirror sheets are lightweight and easy to work with, making them ideal for a variety of applications.