Ever wonder why aluminum composite panels (ACP) have become a popular material for false ceilings? From its light weight to the sleek look it gives buildings, it is no surprise it is in so much demand today.

In this article, you will discover eight benefits of aluminum composite panels you did not know about. But before delving into the advantages, let’s briefly explain what aluminum composite panels are made of.

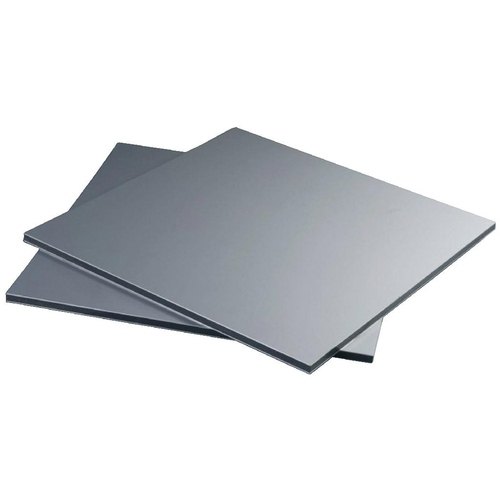

What Are Aluminum Composite Panels?

Aluminum composite panels are multi-layered panels with two aluminum sheets bonded to a non-aluminum core. The core is made of polyethylene or fire-retardant mineral-filled core. While polyethylene cores are lighter and more affordable, fire retardant cores, although more expensive, provide a higher level of fire protection, so it is preferred for larger and taller buildings.

Advantages of Using Aluminum Composite Panels for False Ceilings

Here are some of the benefits you get from using aluminum composite panels for false ceilings.

Lightweight

One of the things aluminum composite panels are well-known for is their light weight. This feature makes them very easy to install and work with. On top of that, they are extremely durable too. ACP’s lightweight does not compromise its strength.

Durable and Long-Lasting

Aluminum composite panels can last longer than wood and glass, as well as other false ceiling materials such as fiber, metal, etc. Wood is susceptible to termite attacks and warping, while glass is brittle. ACP, on the other hand, can withstand harsh weather conditions and UV rays, making it perfect for outdoor and indoor applications.

Heat and Sound Insulation

The primary purpose of false ceilings is to enhance the beauty of the interior of the building and provide sound and thermal insulation, which keeps the room cool and noiseless. The polyethylene core that makes up aluminum composite panels is an effective sound and heat insulator, making it a perfect material for false ceilings.

Easy to Install

Due to its light weight, working with aluminum composite panels is such a breeze compared to heavier materials such as glass. You can easily cut, fold, and shape it to your desired size with no hassle, saving you stress and time.

Fire-Resistant and Safe

This is one of the reasons why aluminum composite panels are highly sought after. Aluminum composite panels are made with fire-resistant mineral core, which is a building material that can help prevent fire and its ripple effects. This is why it is essential for large buildings such as schools, hospitals, and industries where fire safety is most important.

Versatile in Design and Customization

When we talk about versatility, ACP takes all the glory. Aluminum composite panels can be easily folded, bent, and cut into different sizes. That’s not all; you can have your ACP in any colour and finish. So, if you need it to complement the colour of your home or brand or you have a specific feeling you want to achieve, ACP can give you that.

Low Maintenance and Easy to Clean

ACPs are already pre-treated with a protective layer, so they do not rust or require painting. You only need mild soap and a damp cloth to clean aluminum composite panels.

Variety of Sizes & Colour Choices

ACPs are available in different sizes and colours so that they can fit perfectly into any ceiling design. If you need ACP to match the theme of your space and style effortlessly, Canada Plastics and Belting, Inc. will create a custom one to suit your needs.

The Installation Process for Aluminum Composite Panels for False Ceilings

Installing aluminum composite panels can be done in any of the following methods:

Installation Methods

- Welding

- Gluing

- Using rivets

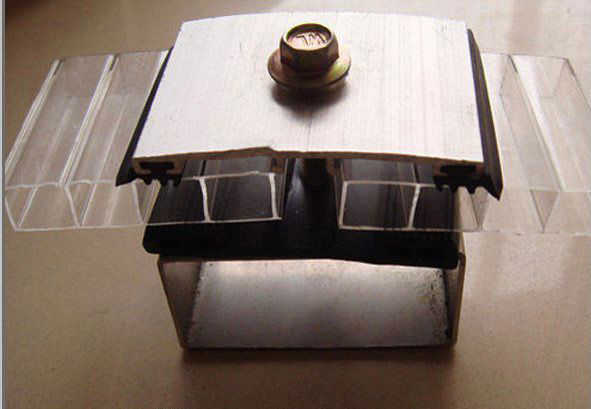

- Profile connection

- Screw connection

- Mechanical connection

Tools Required

- Sharp cutting tool

- Circular saw or jigsaw

- Drill

- Saw

- Rivet gun

- Sealant

Installing Aluminum Composite Panels

- Cut the panels along the cutting line to ensure straight and square edges

- Ensure the enveloping edge and supported keel are perpendicular

- Dock the panels close together starting from one corner or middle row

- Ensure straight and staggered seams, avoiding staggering on the same keel

- For double-layer panels, do not let the seams of both layers fall on the same keel

Maintenance and Cleaning of Aluminum Composite Panels

Regular cleaning is essential to maintain the sheets quality of aluminum composite panels. But not to worry, cleaning is quite simple. Follow the steps below.

Do’s and Don’ts of Cleaning Aluminum Composite Panels

- Do not clean your aluminum composite panel when the temperature is higher than 40°C

- Do not use strong alkali or acid detergent

- Clean a small piece to test it is safe before cleaning the entire part

- Clean from top to bottom and follow it immediately with a proper rinsing with water to completely remove the cleansing agents

Cleaning Methods and Precautions

- Checking the temperature is essential. If you clean aluminum composite panel sheets at freezing temperatures, the water solution will freeze on the surface of the ACP. Similarly, if you clean ACP in hot temperatures, the heat will dry it quickly, leaving soap marks on the surface.

- You can use an isopropyl solution if mild soap and water don’t give the best results

- Avoid using a sponge, squeegee, or any material that can scrub the painted surface

Choose Canada Plastics and Belting Inc. for Aluminum Composite Panels in Toronto

Aluminum composite panels are a versatile and durable material for false ceilings. They come in different colours and finishes that can complement your theme. They are also lightweight, have fire-resistant properties, and require little maintenance. Use aluminum composite panels for your next false ceiling project and see the ease of use for yourself. Contact us today or call us at (416) 291-3036 for a free quote.

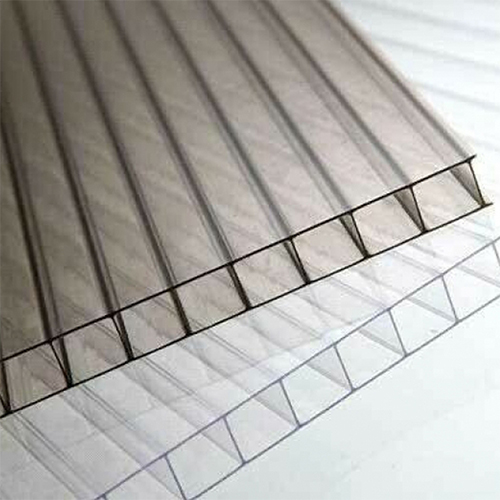

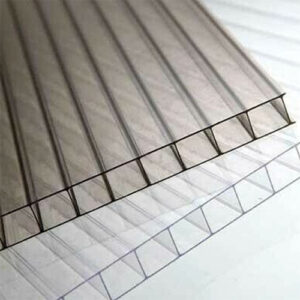

Polycarbonate sheet

Polycarbonate sheet

If you’re enthusiastic about home aesthetics, then you’ll be aware that a good design doesn’t only apply to the more open places in your house, such as the living room and the porch. Your bathroom deserves just as much attention as these areas, so it’s pretty annoying to have your walls stained and damaged from exposure over time to bathwater.

If you’re enthusiastic about home aesthetics, then you’ll be aware that a good design doesn’t only apply to the more open places in your house, such as the living room and the porch. Your bathroom deserves just as much attention as these areas, so it’s pretty annoying to have your walls stained and damaged from exposure over time to bathwater.