Aluminum composite panels (ACP) refer to thin panels of two coiled aluminum sheets without an aluminum core. They are made with polyethylene and a fire-resistant filler. ACPs are popular for their fine finishes and lightweight properties.

In this piece, we list some amazing properties of aluminum composite panels that make them popular for building projects.

Benefits of Aluminum Composite Panels

Lightweight

When it comes to coating or finishing surfaces, aluminum composite panels are preferred because they are lightweight. Aluminum composite panels are approximately 66% lighter than materials like steel and other metals, weighing as low as 4.6 kg per square meter.

Available in Different Shapes, Sizes, and Colours

Aluminum composite panels come in a variety of shapes, sizes, and colours. They can be used to coat different types of systems as well as for creative projects with a wide array of colours available. They can also be cut to fit specific sizes and shapes if the need arises.

Cost-Effective

Aluminum composite panels are cost-effective building solutions because they are easy to use and cost less to maintain than other metal options. They also cost less to install in terms of labour and purchasing materials.

Anti-Corrosion

Aluminum composite panels are pretreated with a protective coating that provides additional protection from corrosion. However, the aluminum panels also release a thin layer of aluminum oxide that keeps the panel from corroding when exposed to air. This makes it easy to maintain the external appearance of the panels.

Low Cost of Maintenance

Aluminum composite panels require very little to no maintenance compared to other finishes like steel and wood which require a lot of maintenance and can be quite expensive to maintain. Aluminum composite panels require cleaning once a year; however, it’s best to contact professionals to handle the cleaning.

Highly Functional

Aluminum composite panels are highly functional in that they are available in different shapes, sizes, colours, and even types and they can be used for their thermal properties, insulation of sound, and wind. They are also easy to clean and can be used to reduce the cost of energy. Aluminum composite panels can also be recycled.

Safe to Use

Aluminum composite panels are built with fire-resistant materials and are even earthquake-resistant making them a safe option for building adventures. There are reduced risks of fire outbreaks as well as lower chances of damaging structures due to earthquakes and small disasters.

Eco-Friendly

Aluminum composite panels are environmentally friendly because they can be recycled to create other products. Also, they are made from recycled materials like aluminum, minerals, and a few other polymers. Aluminum composite panels can retain all properties during their making and design stage.

Durability

Aluminum composite panels are durable due to the non-corrosive characteristics that keep them from getting damaged easily. Also, their ability to be combined with other products makes them last longer; thereby, making them a good option for building projects.

Good Design Options

Another amazing property of aluminum composite panels is that there are numerous design options to choose from depending on the type of project or the type of finishing required. They are available in different colours and textures, which makes them very versatile for building projects.

Applications of Aluminum Composite Panels

Some applications of aluminum composite panels include:

- Lining interior surfaces like walls, cupboards, tables, kitchen units, wardrobes, and even ceilings

- Coating all types of exterior surfaces

- Covering spaces like the interior surfaces of subways, columns, tunnels, telephone booths, and even renovation projects

- Making signage, building kiosks, fascias, and even POP projects

Methods of Installing Aluminum Composite Panels

There are several methods for installing aluminum composite panels in buildings and they include:

Welding

Hot air welding with the aid of a solder is the most common method of installing aluminum composite panels. This method is preferred for the strength of the connection created and the

joint can last a long time without repairs.

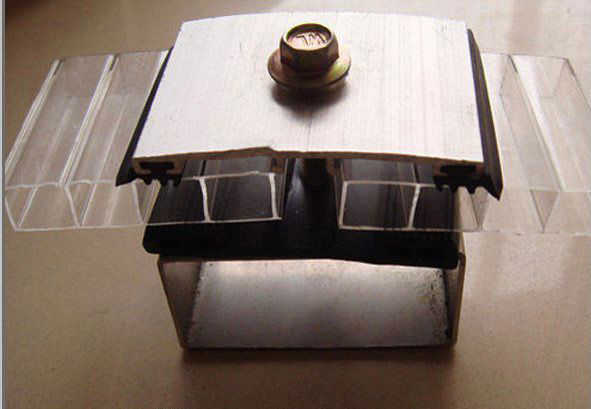

Screwing

Aluminum composite panels can be attached by screws. This method is also durable and can be used for both interior and exterior surfaces. Gaskets are used for external screw installations.

Gluing

Another method of installing aluminum composite panels is with the use of metal glues or other high-tension adhesives. This is another long-lasting method of installing aluminum composite panels; however, this method is not advised for use in areas that are exposed to moisture.

Contact Canada Plastics & Belting for Aluminum Composite Panels in Toronto

The best aluminum composite panel installation result is obtained when the job is done by professionals. If you’re looking for ACP in Toronto, look no further than Canada Plastics & Belting Inc. We are proud to be a top aluminum composite panel distributor in Toronto and we offer a wide selection of aluminum composite panels in multiple colours, sizes, and thickness options. Contact us today for all your aluminum composite panel needs or call us at 416-291-3036 for a free quote.